Nano oil displacement agent based on destroying oil-rock interaction as well as preparation method and application of nano oil displacement agent

An oil-displacing agent and nanotechnology, applied in the field of nano-oil-displacing agent and its preparation, can solve the problems of not easy peeling, dispersion, poor stability, destroying oil displacement performance, etc. The effect of oil displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The embodiment of the present invention also provides a preparation method of a nano-oil displacement agent based on destroying oil-rock interaction, comprising:

[0043] S1, mix the aldehyde group-containing reducing agent with water, and ultrasonicate for 15 minutes to obtain a reducing agent solution;

[0044] S2, adding the aminosilane coupling agent to the reducing agent solution and dissolving to obtain the first reaction solution;

[0045] S3, the first reaction solution is placed in a constant temperature water bath, stirred until the solution reaction changes from colorless to yellow, to obtain the second reaction solution;

[0046] S4, in the second reaction solution, add pH regulator, make the reaction terminate, obtain the third reaction solution;

[0047] S5. Dialyzing and separating the third reaction solution to obtain a nano-oil-displacing agent based on destroying the oil-rock interaction.

[0048] Preferably, the addition rate of the aminosilane coup...

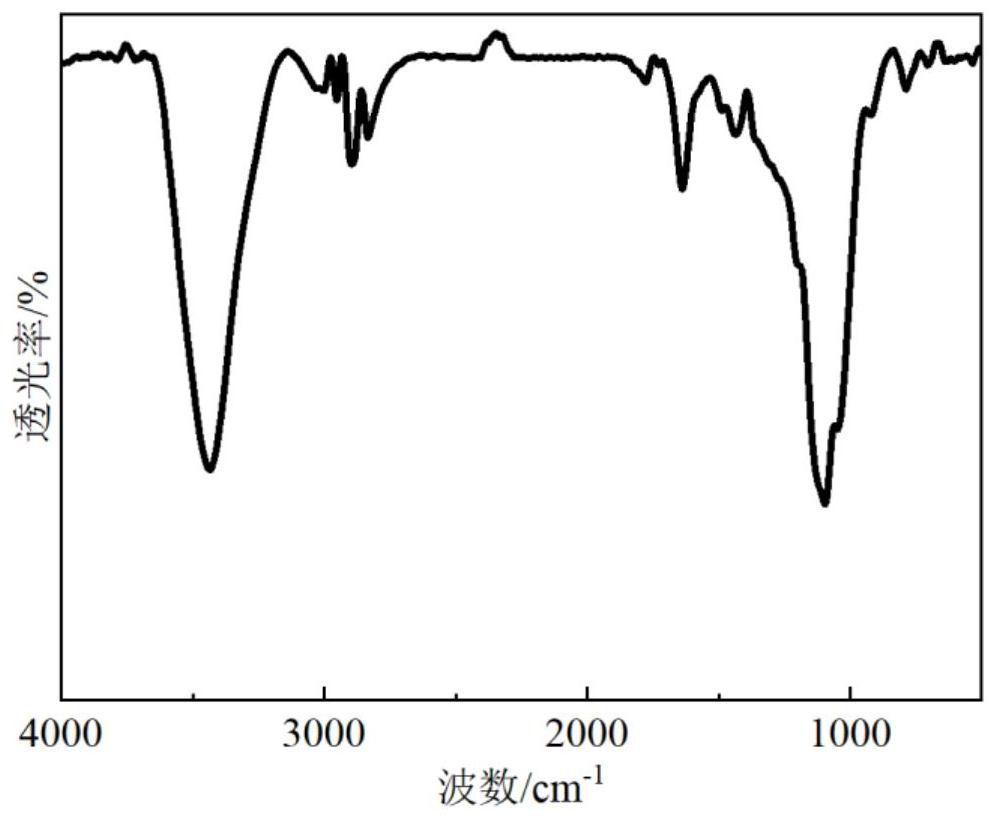

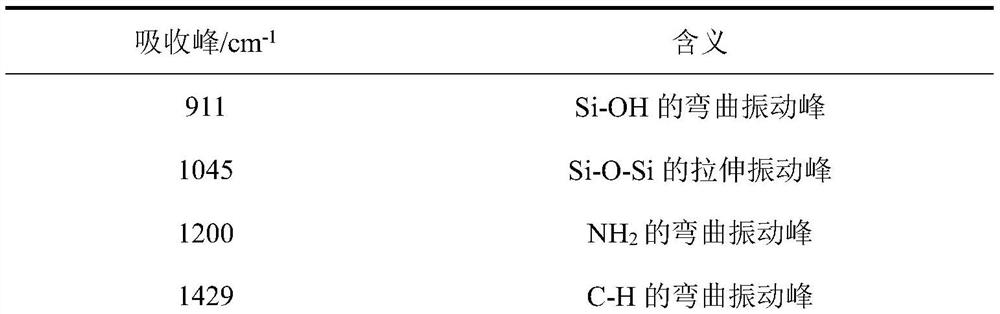

Embodiment 1

[0065] A nanometer oil-displacing agent based on destroying oil-rock interaction includes the following components by weight: 12% of an aldehyde group-containing reducing agent, 10% of an aminosilane coupling agent, 0.01% of a pH adjusting agent, and the balance is water.

[0066] A preparation method of a nano-oil-displacing agent based on destroying oil-rock interaction, comprising:

[0067] S1, 12g glucose is mixed with 78g water, ultrasonic is 15 minutes, make reducing agent solution;

[0068] S2, use 10g 3-aminopropyl triethoxysilane as aminosilane coupling agent with 0.5g·min -1 The speed is slowly added dropwise to the reducing agent solution and dissolved to obtain the first reaction solution;

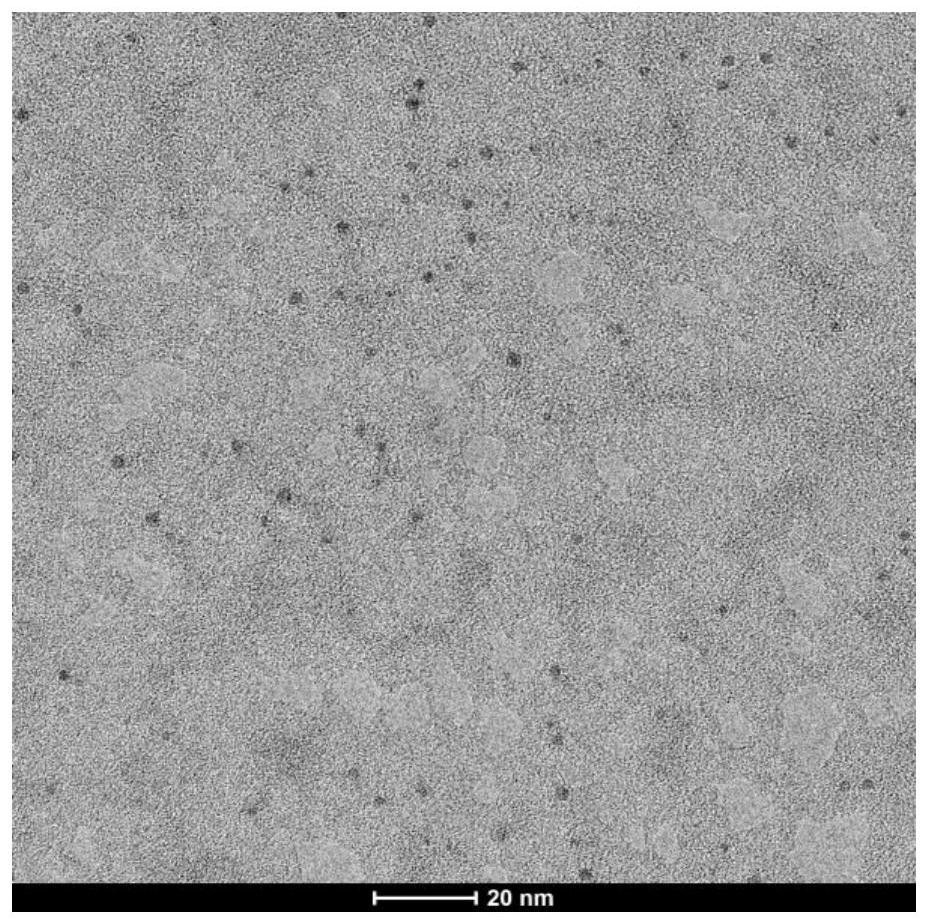

[0069] S3, the first reaction solution is placed in a constant temperature water bath, heated at a constant temperature of 20 DEG C and stirred with a rotating speed of 200 rpm, after 48 hours of reaction, the first reaction solution changed from colorless to light yellow, and...

Embodiment 2

[0077] A nanometer oil-displacing agent based on destroying oil-rock interaction includes the following components by weight: 15% of an aldehyde group-containing reducing agent, 12% of an aminosilane coupling agent, 0.02% of a pH adjusting agent, and the balance is water.

[0078] A preparation method of a nano-oil-displacing agent based on destroying oil-rock interaction, comprising:

[0079] S1, mix 15g of fructose with 73g of water, and ultrasonicate for 10 minutes to obtain a reducing agent solution;

[0080] S2. Use 12g N-(β-aminoethyl-γ-aminopropyl)dimethoxysilane as an aminosilane coupling agent at 0.3g·min -1 The speed is slowly added dropwise to the reducing agent solution and dissolved to obtain the first reaction solution;

[0081] S3, the first reaction solution is placed in a constant temperature water bath, heated at a constant temperature of 40°C and stirred with a rotating speed of 150 rpm, after 24 hours of reaction, the first reaction solution changed from c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com