Blasting method for roadway or tunnel tunneling based on field mixed loading emulsion explosive

A technology of mixing and emulsifying explosives on site, which is applied in blasting and other directions, can solve the problems of less single-hole charge, small excavation section, and application obstruction, and achieve the effects of improving charge efficiency, reducing the number, and increasing footage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the scope of the described embodiments.

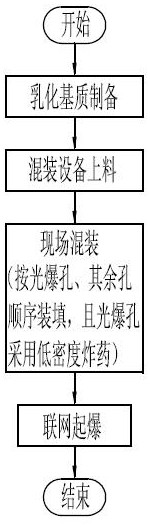

[0014] see figure 1 , a blasting method for roadway or tunnel excavation based on on-site mixing of emulsion explosives, comprising the following steps:

S1, emulsification matrix preparation: at the explosive production point or ground preparation station, the emulsification technology combining mechanical colostrum and static seminal milk is used to prepare the emulsification matrix;

S2, equipment feeding: put the prepared emulsified matrix into the emulsified matrix silo of the on-site mixing equipment, and configure different concentrations of sensitizers in the multiple sensitizer bins of on-site mixing;

S3, on-site mixing: move the mixing equipment to the vicinity of the tunnel face, use the mixing equipment to mix the emulsion explosives on-site and charge the blasting holes o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com