Directional well target depth design method

A design method and technology for directional wells, which are applied in the fields of seismology, instrumentation, climate sustainability, etc. for logging records, and can solve the problems of productivity reduction of unreachable reservoirs, errors between design depth and actual drilling depth, etc. To achieve the effect of widespread promotion, easy operation and good practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

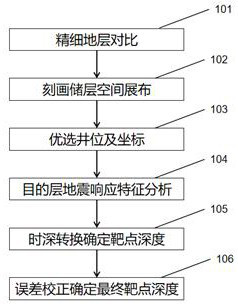

[0045] like figure 1 As shown, the directional well target depth design method includes the following steps:

[0046] Step 101, carry out a fine stratigraphic comparison study according to the completed directional well data, and confirm the corresponding relationship of sand bodies;

[0047]According to the drilled directional well data, combined with core observation, according to the vertical sedimentary cycle characteristics, combined with lithological and electrical characteristics, the target interval in the study area is divided into sand layers, and on this basis, the oil-bearing sand groups are divided into small layers. and the division of single sand bodies; use analytical laboratory and well logging data to analyze the development characteristics of the reservoir plane, clarify the provenance direction and law, and determine the corresponding relationship between sand bodies between wells.

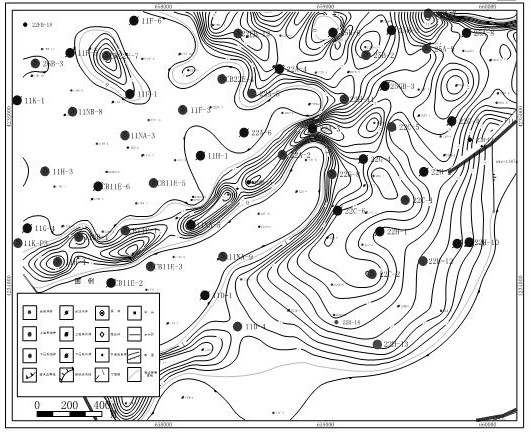

[0048] Step 102: Determine the spatial distribution characteristics of th...

Embodiment 2

[0059] Taking Well 22H-13 as an example, the design method of the target depth of the directional well is described in detail. The steps are as follows:

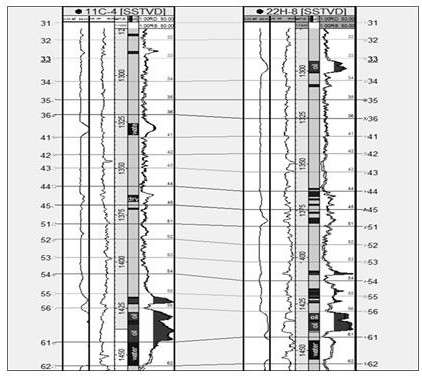

[0060] (1) According to the completed drilling data, combined with core observation, according to the vertical sedimentary cycle characteristics, combined with lithological and electrical characteristics, the target interval in the study area is divided into sand layers, and on this basis, the oil-bearing sand groups are divided into small layers and the division of single sand bodies. At the same time, the completion drilling analysis, testing, logging and other data are used to confirm the corresponding relationship between sand bodies in the target layer. The comparison chart of each layer is as figure 2 shown.

[0061] (2) According to the lithology data of the completed well core, analyze the physical properties of the test, the logging curve and the oil-bearing characteristics, interpret the effective thickness of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com