Perovskite film rhythmic deposition production method and equipment

A production equipment and production method technology, applied in the field of perovskite film rhythmic deposition production method and equipment, can solve problems such as lattice distortion, overgrowth stoichiometric ratio, abnormality, etc., and achieve improved reaction speed and high reliability with reproducible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

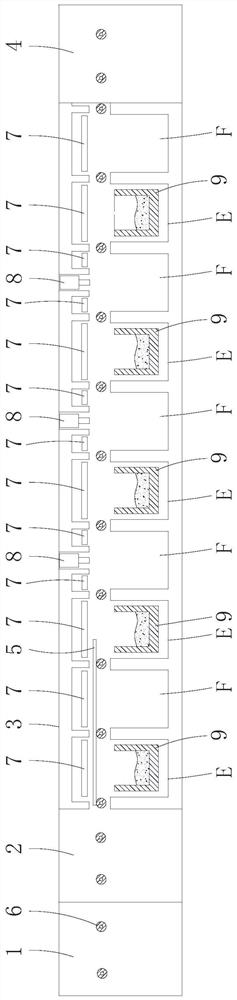

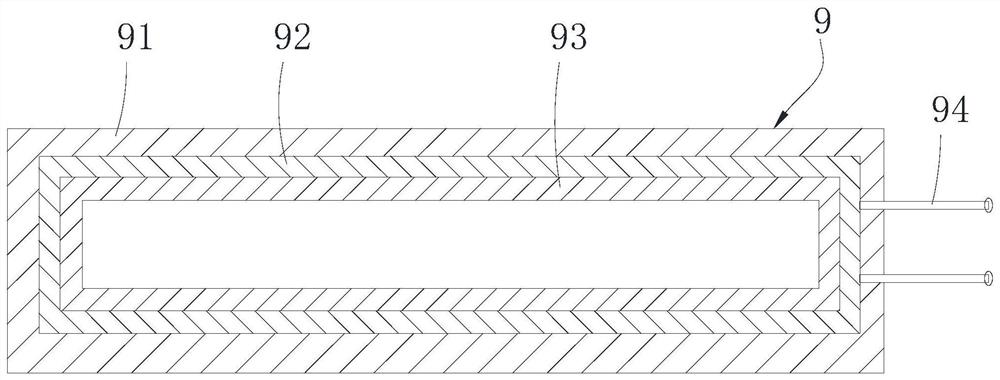

Please continue to refer to the attached figure 2 As shown in the figure, the first perovskite film rhythm deposition production equipment disclosed in the present invention is composed of a sample injection chamber 1, a heating chamber 2, a deposition reaction chamber 3 and a sample output chamber 4, wherein the sample injection chamber 1 is similar to Due to the effect of the transition chamber, the substrate 5 to be deposited enters the low pressure chamber from the atmospheric pressure outside the chamber, and the heating chamber 2 is communicated with the deposition reaction chamber 3, and the temperature of the chamber is higher than that of the deposition reaction chamber 3, so that the substrate 5 to be deposited can be rapidly heated up. to the reaction temperature, and then enter the deposition reaction chamber 3 for reaction. The transport of the substrate 5 to be deposited is realized by a roller 6 driven by a servo motor, and the deposition surface of the substrat...

Embodiment 2

Please refer to the attached Figure 4 As shown, this embodiment is a rhythmic production method in which the length of the reaction section is constant and the length of the deposition section is gradually reduced, derived from the most basic perovskite thin film rhythmic deposition production equipment in Example 1. Taking the combination of three evaporation sources in the first deposition section as an example (there will be more in actual production), the basic process of using the perovskite film rhythmic deposition production equipment of this embodiment to prepare a perovskite film includes the following steps:

Step 21: Filling the chamber 3 of the deposition reaction chamber with nitrogen to make the pressure in the chamber reach normal pressure, then open the upper cover of the chamber, install the evaporation sources in the first to third evaporation source installation grooves, and combine them into the first deposition section, Then the fourth evaporation source i...

Embodiment 3

Please refer to the attached Figure 5 As shown, this embodiment is a rhythmic production method in which the length of the deposition section is constant and the length of the reaction section is increased, which is derived from the most basic perovskite thin film rhythmic deposition production equipment in Example 1. The basic process of preparing the perovskite thin film using the perovskite thin film rhythmic deposition production equipment of this embodiment includes the following steps:

Step 31. Fill the deposition reaction chamber 3 with nitrogen to make the pressure in the chamber reach normal pressure, then open the upper cover of the chamber, and install the evaporation source in the first evaporation source installation slot as the first deposition section, and then the second evaporation source. The source installation slot was left empty as the first reaction stage, then the evaporation source was installed in the third evaporation source installation slot as the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com