Positive electrode framework structure of metal/metal oxide lithium-sulfur battery

A skeleton structure, lithium-sulfur battery technology, applied in battery electrodes, lithium storage batteries, structural parts, etc., can solve the problems of limiting LiPS conversion catalytic activity, low conductivity of metal oxides, and unsatisfactory electrocatalytic activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

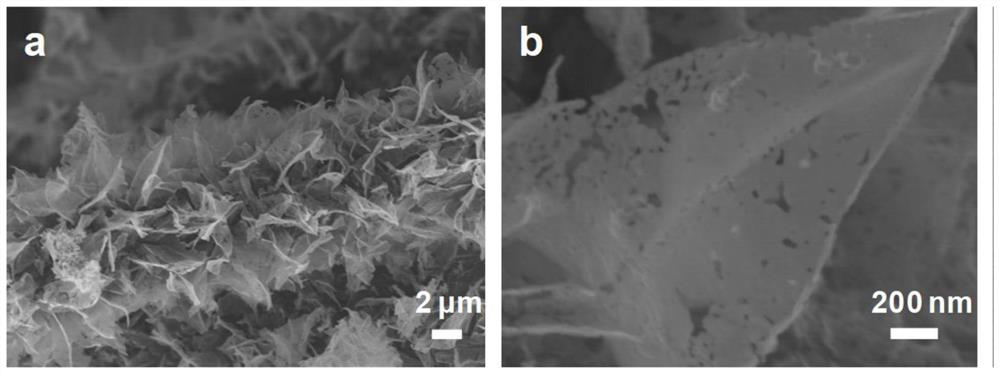

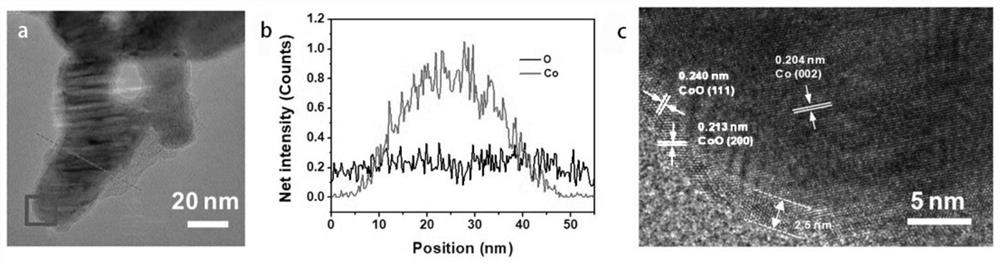

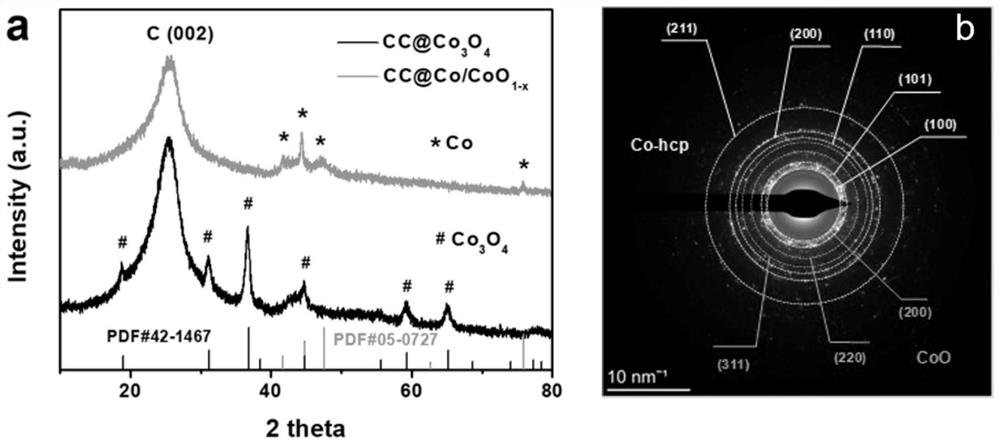

[0024] A two-dimensional porous core-shell structure combined with oxygen vacancies in CC@Co / CoO 1-x The cathode skeleton structure of the nanosheet array lithium-sulfur battery is characterized by, such as figure 1 shown, CC@Co / CoO 1-x With a uniform nanosheet array structure, the CC@Co / CoO 1-x Nanosheets with nanopores originating from Co 3 O 4 Huge volume shrinkage (about 49%) during particle conversion to Co; the CC@Co / CoO 1-x The unique 2D porous structure of nanosheet arrays makes CoO 1-x The nanosheets have high active sites, which have strong chemical interactions with LiPS, which are beneficial to promote the cleavage of S-S bonds in LiPS. In addition, Co / CoO 1-x Seamlessly joined together by many irregular nanosheets originating from H 2 reduced Co 3 O 4 The Co atoms obtained from the nanoparticles are polymerized, and this structure is conducive to accelerating charge transfer and enhancing structural stability. like figure 2 a and 2b, STEM and line scan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com