Artificial graphite, method for preparing artificial graphite, negative electrode comprising artificial graphite, and lithium secondary battery

A technology of artificial graphite and graphitization, applied in the direction of secondary batteries, graphite, negative electrodes, etc., can solve the problems of reduced productivity of secondary batteries, defects in electrical properties, etc., to improve safety, and solve the effects of fire and explosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

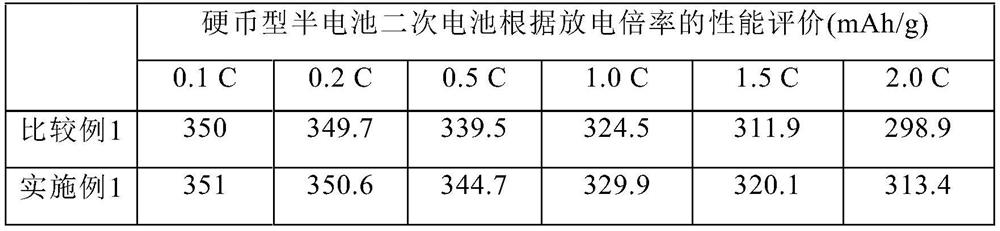

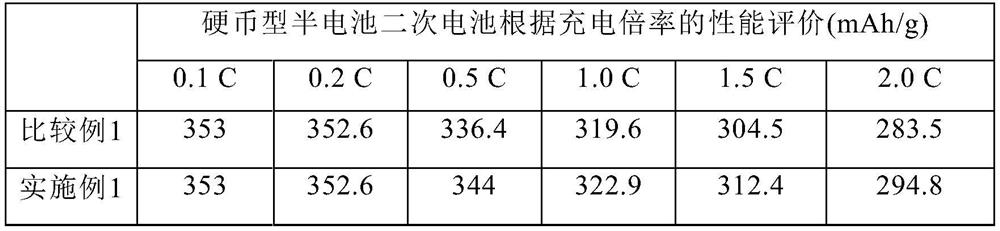

Examples

Embodiment 1

[0106] (1) Preparation of artificial graphite

[0107] First, coke as a raw material is pulverized to an average particle size (D 50 ) was 10 μm, and a first deironing treatment was performed using an electromagnetic deironing system under a magnetic force of 36,000 gauss to remove magnetic foreign matter contained in the pulverized coke raw material.

[0108] The de-ironized product was pelletized at 800°C for 24 hours using a horizontal pelletizing system.

[0109] The granulated product was heat-treated using an Atcheson graphitization furnace at 2,800° C. for 400 hours, including heating time and cooling time, for graphitization.

[0110] Then, 100 parts by weight of the graphitized product was mixed with 5 parts by weight of pitch (solid pitch) as a carbon coating material using a vertical / horizontal mixer, and carbonization was performed at a temperature of 1500° C. for 24 hours, Thereby carbon coating is performed.

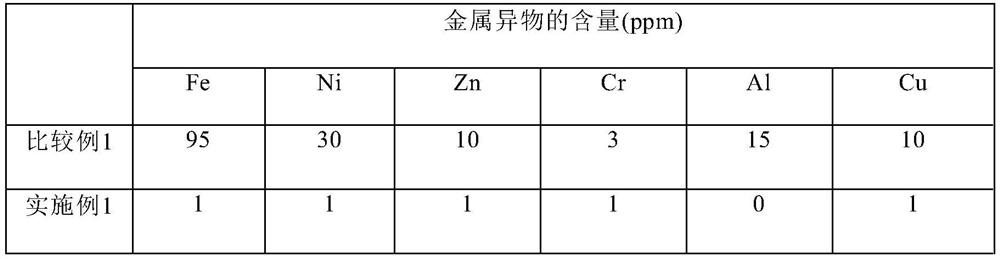

[0111] After that, the second deironing was perfor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| magnetic force | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com