Ornament and manufacturing process thereof

A technology for making crafts and ornaments, which is applied in the direction of decorative art and special decorative structures, etc. It can solve problems such as complicated operation, inability to quickly make ore ornaments, and long process time, so as to achieve simple manufacturing process, improve poor blood circulation, and good color Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

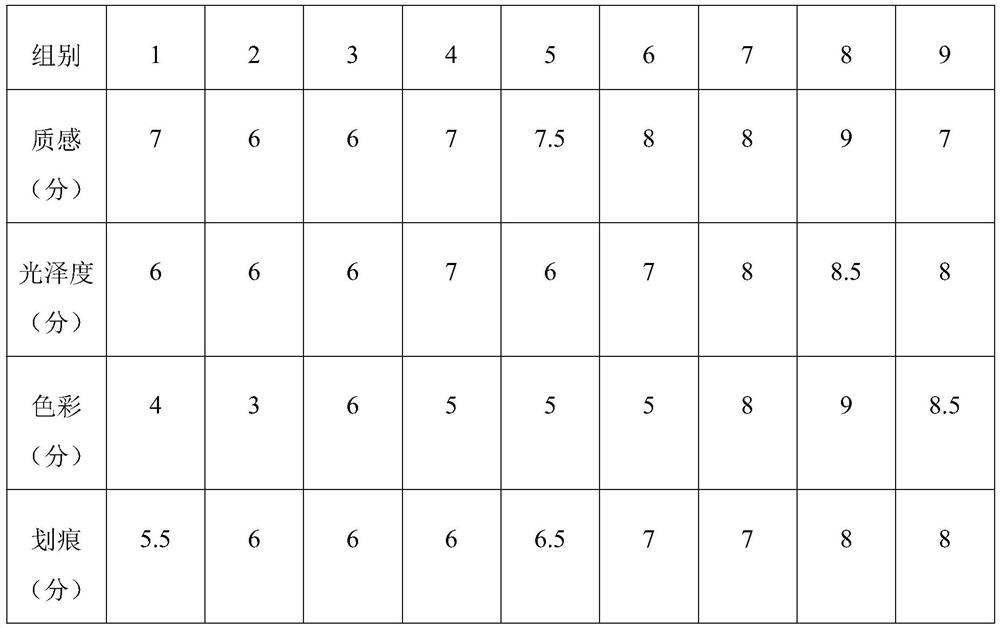

Examples

Embodiment 1

[0040] A production process for an ornament, comprising the following steps:

[0041] Raw materials: 100g Luliang stone and 10g epoxy resin AB glue.

[0042] Mould production: Take jade, wood or paraffin to carve out the designed sample, the sample is the mould;

[0043] Mold prefabrication: place the mold seed in the container, pour silica gel into it, and after the silica gel solidifies, take out the silica gel plate, which is the mold;

[0044] Jewelry production: first grind Lvliang stone into stone powder, the mesh number of stone powder is 10 mesh, then mix the stone powder with epoxy resin AB glue, then pour it into the mold, dry and solidify, and release the mold.

Embodiment 2

[0046] A production process for an ornament, comprising the following steps:

[0047] Raw materials: 200g Bianstone and 40g epoxy resin AB glue.

[0048] Mould production: Take jade, wood or paraffin to carve out the designed sample, the sample is the mould;

[0049] Mold prefabrication: place the mold seed in the container, pour silica gel into it, and after the silica gel solidifies, take out the silica gel plate, which is the mold;

[0050] Jewelry production: first grind the Bianstone into stone powder, the mesh number of the stone powder is 400 mesh, then mix the stone powder with the epoxy resin AB glue, then pour it into the mold, dry and solidify, and release the mold.

Embodiment 3

[0052] A production process for an ornament, comprising the following steps:

[0053] Raw materials: 180g Fugui red and 20g epoxy resin AB glue.

[0054] Mould production: Take jade, wood or paraffin to carve out the designed sample, the sample is the mould;

[0055] Mold prefabrication: place the mold seed in the container, pour silica gel into it, and after the silica gel solidifies, take out the silica gel plate, which is the mold;

[0056] Jewelry production: First grind Fugui Red into stone powder, the mesh number of stone powder is 100 mesh, then mix the stone powder with epoxy resin AB glue, then pour it into the mold, dry and solidify, and release the mold.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com