Profile control and displacement control method and device for fireflood well group

A fire-flooding well group and control-flooding technology, which is used in earth-moving drilling, wellbore/well components, and production fluids, etc., can solve the problems of ineffective production of injected gas, fast gas propulsion, and uneven suction, avoiding the The effect of "fingering" and gas channeling, increasing the swept area and reducing the passing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

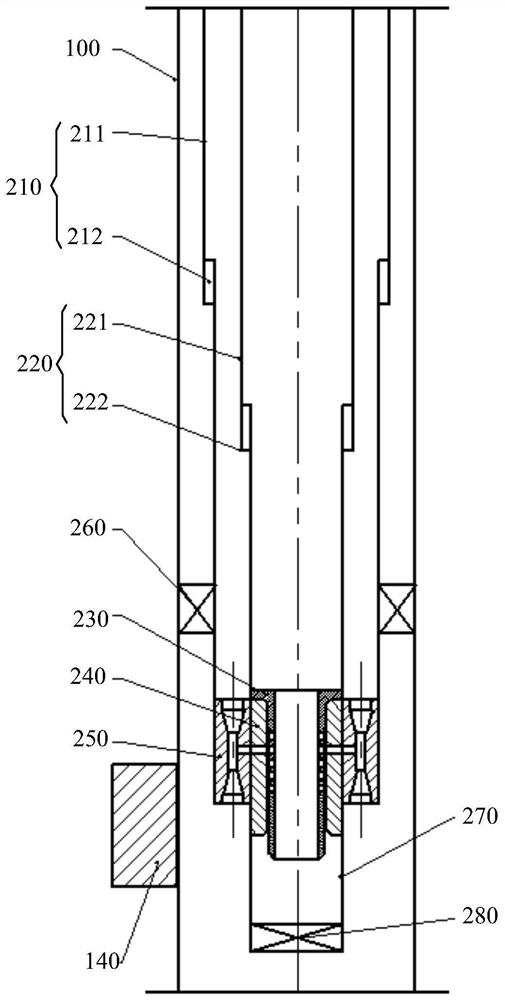

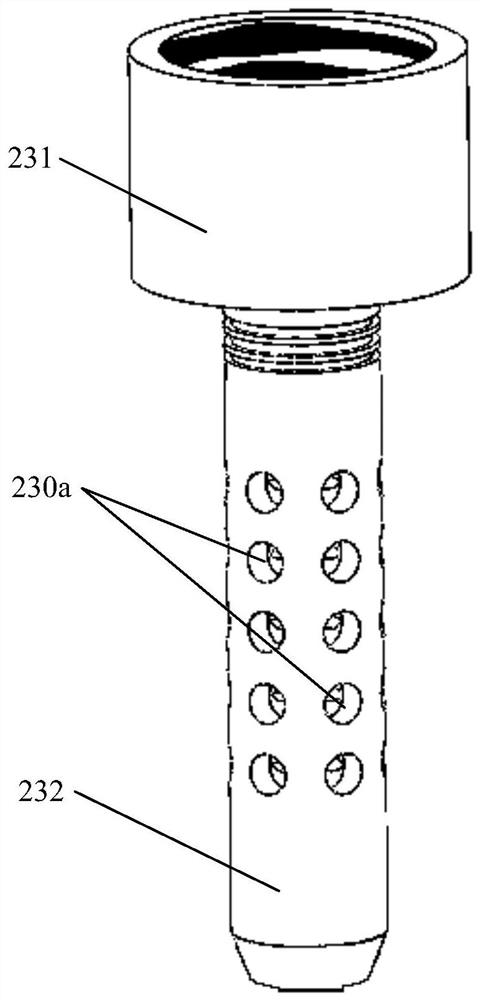

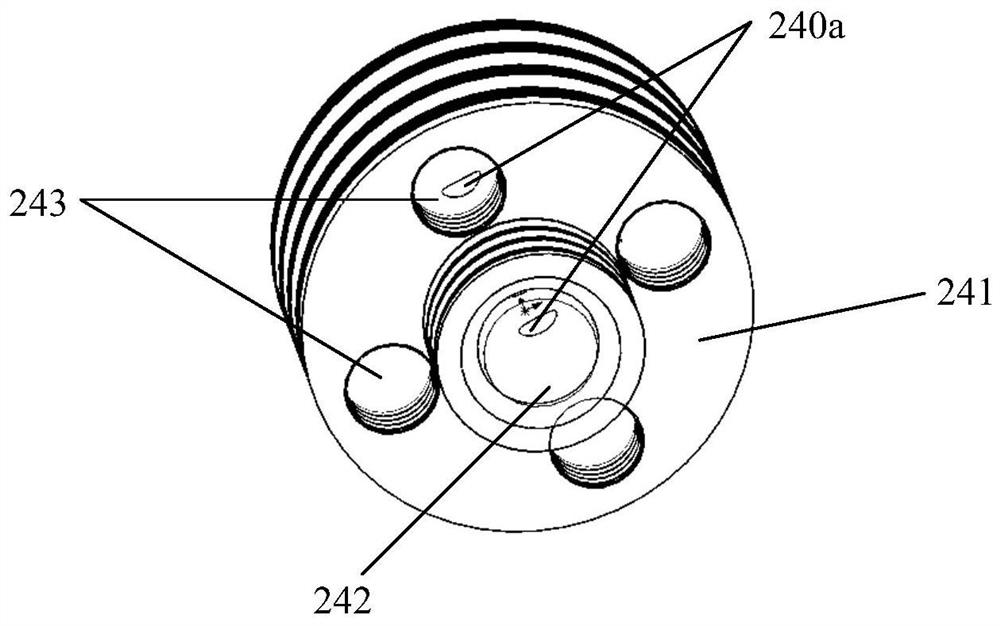

[0042] figure 1 A schematic structural diagram of the profile control and drive device provided in Embodiment 1; figure 2 A schematic structural diagram of the insertion tube in the profile control and drive device provided in Embodiment 1; image 3 It is a schematic structural diagram of the atomizer in the profile control and drive control device provided in Embodiment 1; Figure 4 A schematic structural diagram of the jet tube in the profile control and drive device provided in Embodiment 1; Figure 5 It is a schematic diagram of the change of the front and rear longitudinal upper live lines during the process of profile control and driving measures; Image 6 This is a schematic diagram of the change of the live line on the front and rear planes in the process of profile control and flood control (taking the reverse nine-spot well pattern as an example).

[0043] Among them, L1 represents the longitudinal advance of the live wire before profile control and drive; D1 rep...

Embodiment 2

[0081] This embodiment provides a method for profile control and drive based on the profile control and drive device in the first embodiment, including:

[0082] injecting gas into the annular space between the outer tube 210 and the inner tube 220, so that the gas enters the jet tube 250;

[0083] The liquid is injected into the inner tube 220, so that the liquid enters the jet tube 250 through the insertion tube 230 and the atomizer 240, and the gas and liquid entering the jet tube 250 are mixed to form aerosol and ejected from the jet tube 250, so that the gas The fog can be injected into the formation to produce the effect of profile control and flooding.

[0084] The production process based on the aforementioned profile control and drive device will be explained below. The production process includes: going down stage, ignition stage, normal gas injection stage, profile control and flooding stage.

[0085] In the downhole stage, the aforementioned profile control and d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com