Universal spiral air inlet type molten pool smelting furnace

A molten pool smelting furnace and air-inlet type technology, which is applied in the field of universal spiral air-inlet molten pool smelting furnace, can solve the problems of furnace body damage and prolong the cleaning cycle of the molten pool furnace, so as to ensure the ventilation performance and prolong the cleaning cycle , cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

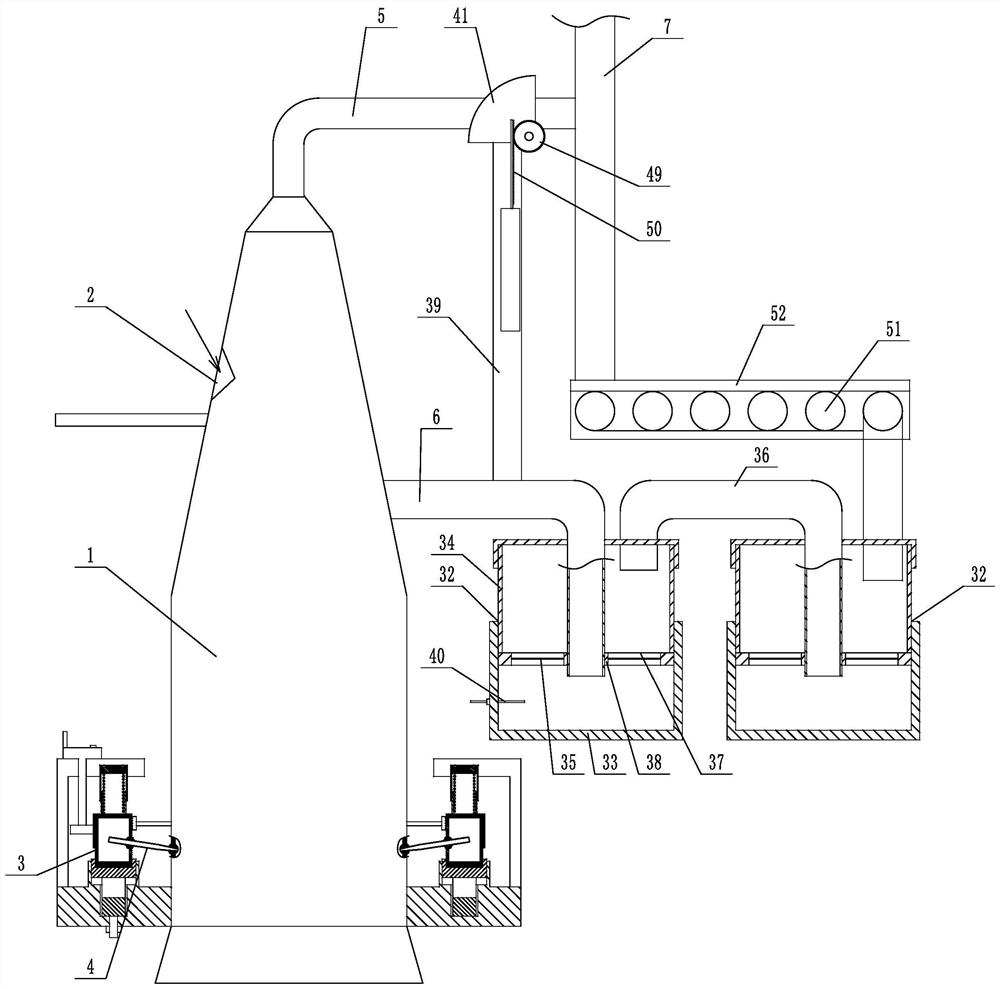

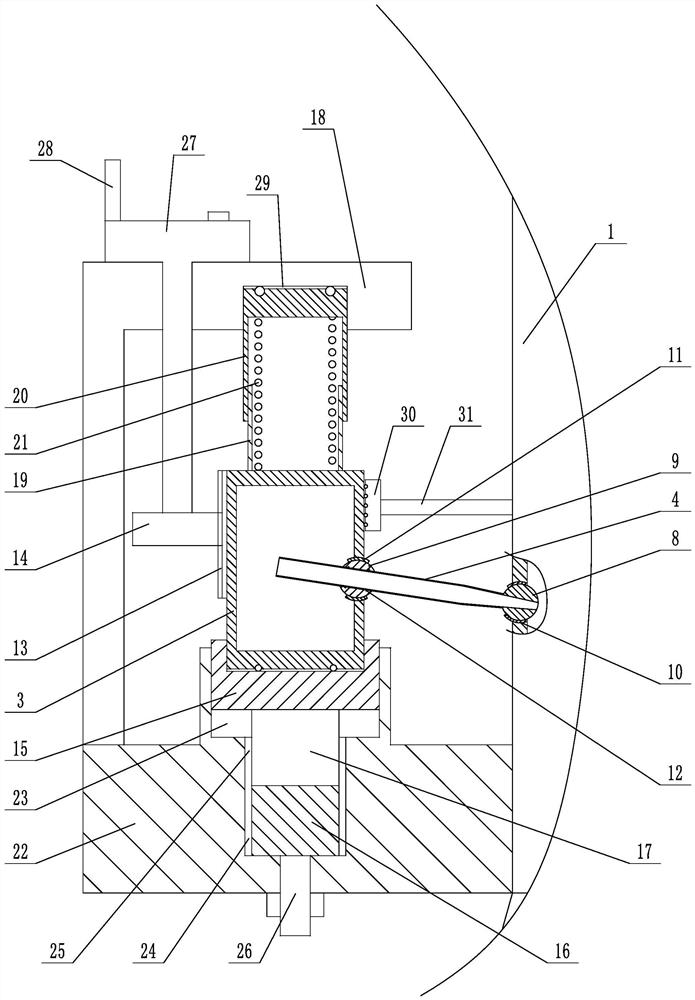

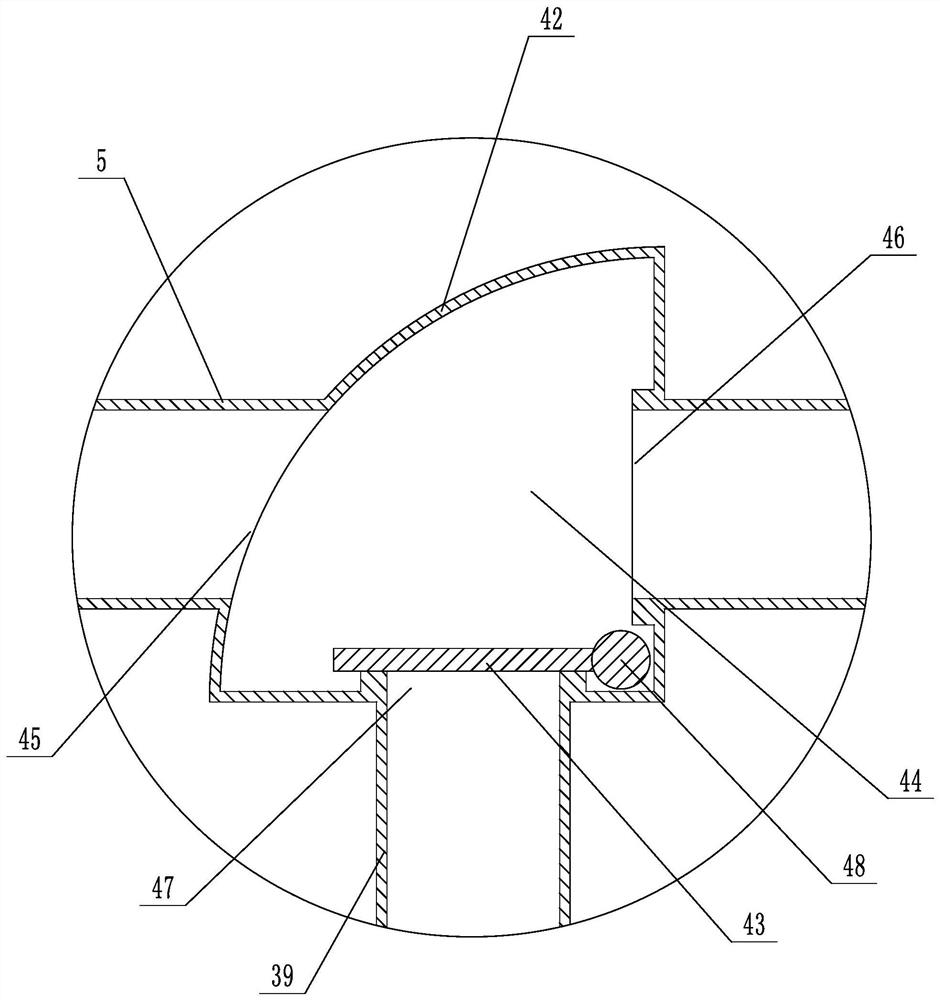

[0027] Example: a universal spiral inlet type molten pool melting furnace (see attached figure 1 , attached figure 2 , attached image 3 ), including the furnace body 1, the air inlet assembly is installed at the lower part of the furnace body, and the feeding port 2 is arranged on the upper part of the furnace body; between the furnace bodies. One end of the intake branch pipe can be universally rotated and installed on the furnace body, and the other end of the intake branch pipe can be universally rotated and installed on the intake manifold. The angle is adjusted, and the air inlet branch pipe is inclined to the furnace body to generate a spiral air flow in the furnace body; the furnace body is connected to the flue gas pipe 5 and the dust pipe 6, the flue gas pipe is connected to the suction pipe 7, and the dust pipe and the suction pipe are connected. The dust removal unit is connected between them, and the flue gas pipe and the dust pipe are respectively placed abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com