Method for treating high-salinity lithium-containing wastewater generated in lithium battery precursor preparation

A wastewater treatment and high-salt wastewater technology, applied in water/sewage treatment, heating water/sewage treatment, water/sludge/sewage treatment, etc., can solve high energy consumption, low efficiency, easy to block evaporator tubes, etc. problems, to achieve the effect of increasing recovery rate, reducing impact and prolonging cleaning cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

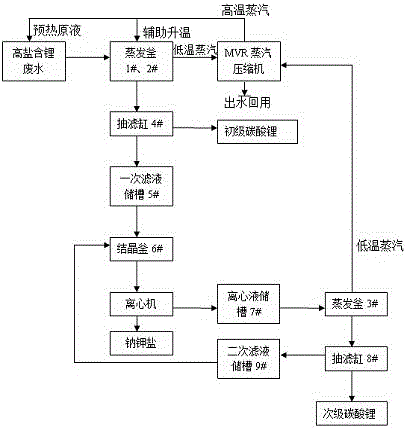

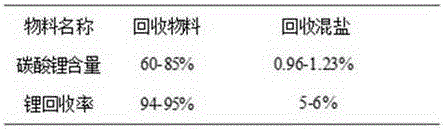

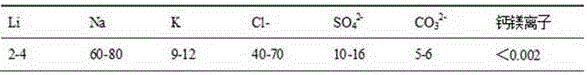

[0034] In this design, the lithium-containing high-salt wastewater discharged by an enterprise with an annual production of lithium carbonate and lithium hydroxide totaling 3,000 tons in a city in the northwest is used as the treatment object. The physical index of lithium-containing wastewater is pH=10-13, and the specific gravity is 1.05-1.10. , COD>2000, solid content<2%. The main components of wastewater are shown in Table 1.

[0035] Table 1. Lithium-containing high-salt wastewater composition list (g / L)

[0036]

[0037] The specific implementation steps are: (1) Negative-pressure evaporation of lithium-containing high-salt wastewater; (2) Recycling of negative-pressure low-temperature saturated steam through the MVR two-stage compressor after secondary heating; (3) Separation of high-temperature insoluble high-grade lithium salt; (4) Separation of crystalline sodium and potassium salts; (5) Separation and recovery of low-grade lithium salts and sodium and potassium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com