Device and method for automatically measuring foam characteristics of lubricating oil

A measuring device and lubricating oil technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of low test efficiency, low degree of automation, time-consuming and labor-consuming, etc., to improve accuracy and test efficiency, and improve automation Level, the effect of shortening the constant temperature time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

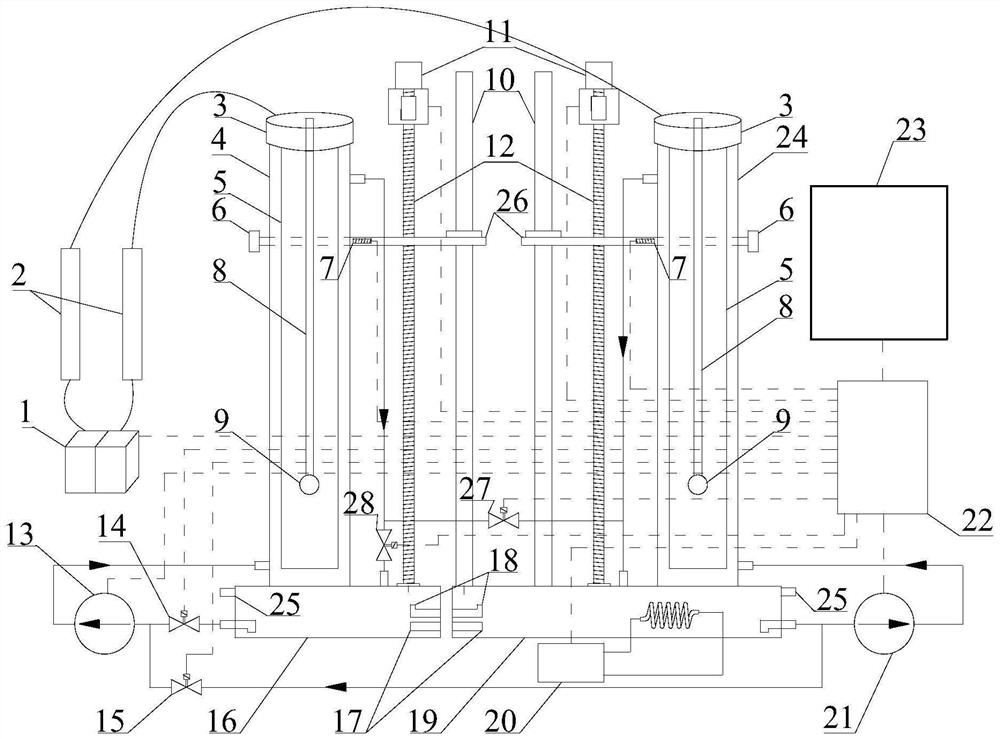

[0025] The principle of automatic determination of lubricating oil foam characteristics is to use the integrated control system to switch between different test procedures; The operation data of the movable photoelectric detection system and the servo motor are used to determine and measure the foam volume. as Figure 1As shown, the measuring apparatus comprises a high temperature bath system, a low temperature bath system, a high temperature constant temperature circulation system, a low temperature constant temperature circulation system, a pneumatic system, a photoelectric detection system and an integrated control system 22.

[0026] The air pump 1 of the gas path system is connected to the cylinder cover 3 through the flow meter 2 and the gas path; The high temperature bath system includes a measuring cylinder cover 3, a high temperature water bath cylinder 4, and a measuring cylinder 5; Cryogenic bath system includes measuring cylinder cover 3, cryogenic water bath tub 24, me...

Embodiment 2

[0028] The method for automatic determination of lubricating oil foam characteristics includes the following steps:

[0029] S1, to the 2 cylinder 5 respectively pour 190mL lubricating oil samples, the measuring cylinder 5 into the low temperature water bath 24 and high temperature water bath 4 respectively, installed the gas guide and diffusion head 9, cover the measuring cylinder cover 3, connected to the gas path.

[0030] S2, start the test procedure, the system automatically executes the following procedures, until the end of the experiment.

[0031] S3, open the high and low temperature water tank electric heater and refrigeration system, low temperature water tank to 24 °C and high temperature water tank to 93.5 °C.

[0032] S4, open high temperature automatic valve 14, high temperature return valve 28, close low temperature automatic valve 15, low temperature return valve 27, open high temperature circulation pump 13, low temperature circulation pump 21 respectively, the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com