Device and method for eliminating reflected light noise at tail end of optical fiber and manufacturing method

A technology of reflected light and noise, applied in the field of sensing, can solve the problems of insufficient tail, knotting and smearing, and unrecoverable space, etc., to improve measurement accuracy, reduce reflected light noise, and eliminate multiple wavelength reflected light noise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

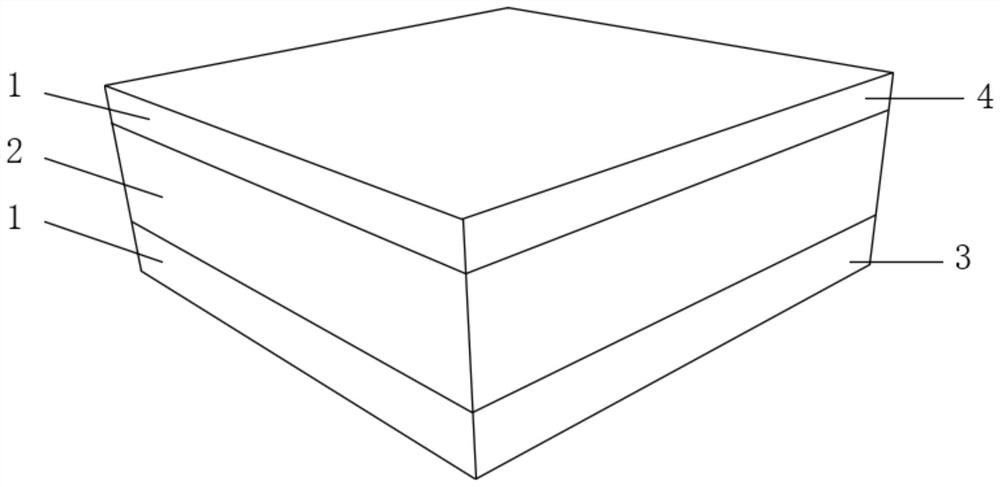

[0038] like Figure 1-2 As shown, this embodiment provides a device, method and manufacturing method for eliminating the reflected light noise from the end of the optical fiber, and the specific technical solution is as follows:

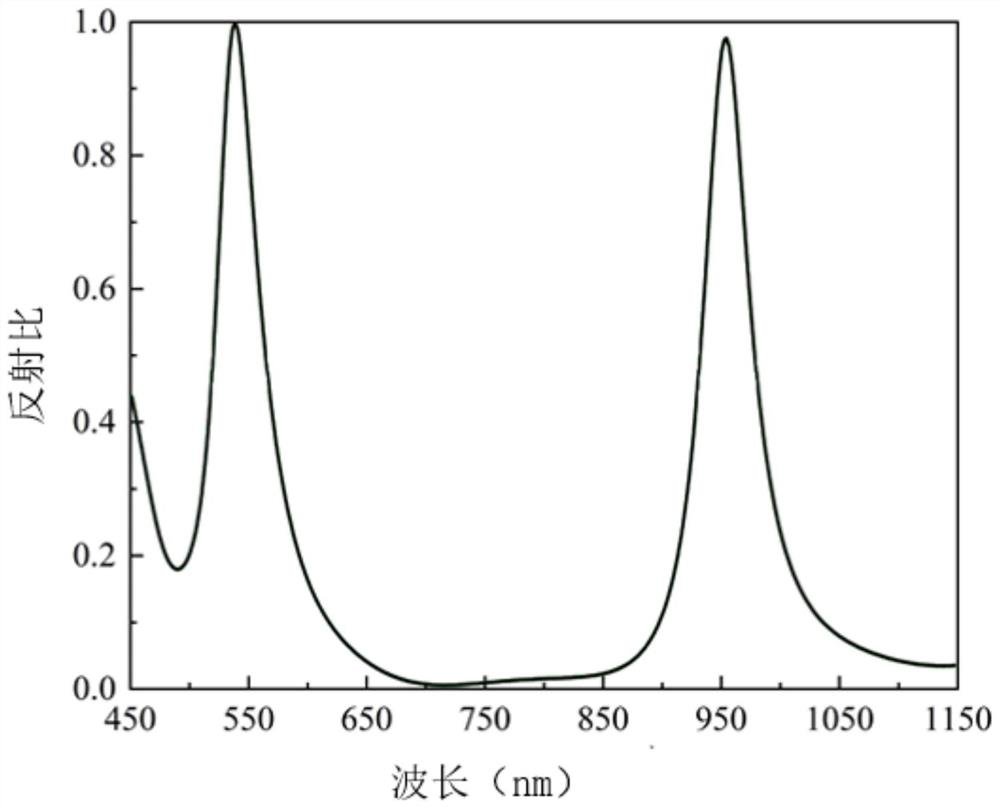

[0039] The scheme of the present invention adopts the absorption and filtering characteristics of the surface plasmon lattice resonance to realize the absorption of the reflected light at the end of the fiber, and eliminates the influence of the noise of the reflected light at the end of the fiber on the measurement. The core part of the device of the surface plasmon lattice resonance unit is as follows: Based on metal-medium-metal ("MIM" for short) nanoarrays, surface plasmons are electromagnetic oscillations formed by the interaction of free electrons and photons in the metal surface region. The interaction between surface charge oscillations and light-wave electromagnetic fields gives surface plasmons many unique and meaningful properties, especia...

Embodiment 2

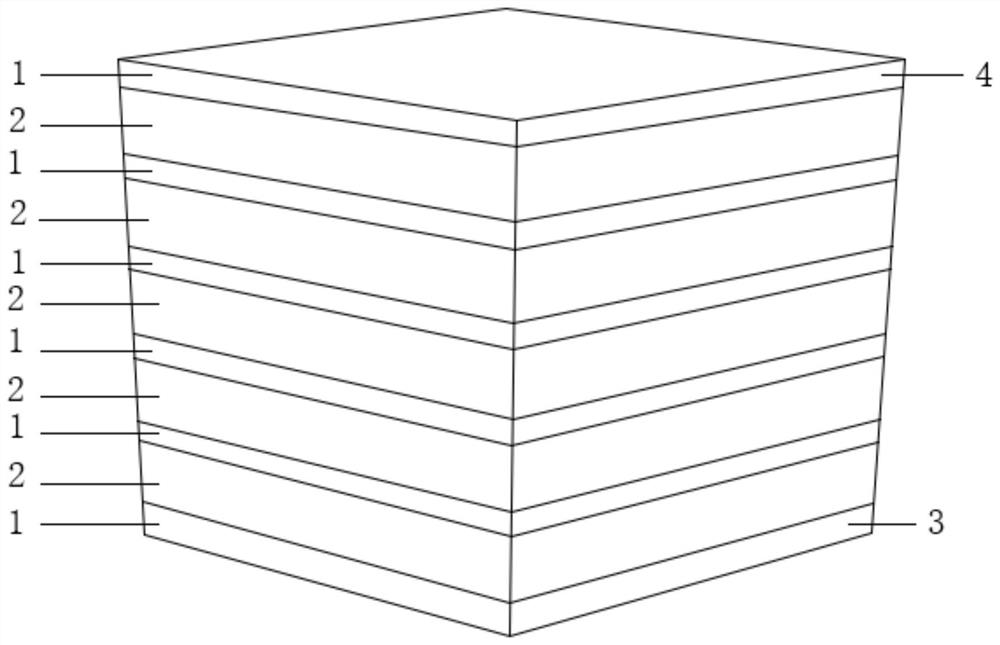

[0054] This embodiment provides a device, method and manufacturing method for eliminating reflected light noise from the end of an optical fiber, such as Figure 3-4 , compared with Embodiment 1, the main difference of this embodiment is:

[0055] The laminated structure includes a multi-layer structure, the head 4 and the tail 3 of the multi-layer structure are both metal ridges 1 , and the multi-layer dielectric and the multi-layer metal ridge 1 are alternately arranged between the head 4 and the tail 3 . Specifically, the stacked structure includes a five-layer structure, the head 4 and the tail 3 of the five-layer structure are both metal ridges 1 , and the five-layer dielectric and the four-layer metal ridge 1 are alternately arranged between the head 4 and the tail 3 . The multi-wavelength absorption is realized by changing the number of layers of the laminated structure, and the reflected light noise of multiple wavelengths at the end of the optical fiber is reduced. Co...

Embodiment 3

[0060] This embodiment provides a device, method and manufacturing method for eliminating the reflected light noise from the end of the optical fiber. Compared with Embodiment 1, the main difference of this embodiment is:

[0061] Specifically, the size of the laminated structure can be changed to achieve the purpose of eliminating the reflection at the end of the optical fiber. Specifically, the refractive index of titanium dioxide 2 is 2.65, the refractive index of air is 1.0, the side length of the square laminated structure is 1 mm, and the thickness of the head 4 is 10nm, tail 3 thickness is 100nm, titanium dioxide 2 thickness is 100nm.

[0062] Other features of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com