Method for detecting chemical components of metal material

A technology of metal materials and chemical composition, applied in the direction of analyzing materials, using wave/particle radiation for material analysis, measuring devices, etc. Effect

Pending Publication Date: 2022-06-10

浙江方圆金属材料检测有限公司

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] Existing detection methods are difficult to accurately measure the content of cobalt, chromium and carbon on metal materials, and it is impossible to know whether the current content of cobalt, chromium and carbon exceeds the standard. At the same time, most of the existing detection methods need to add HF, which has certain safety Hidden danger

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

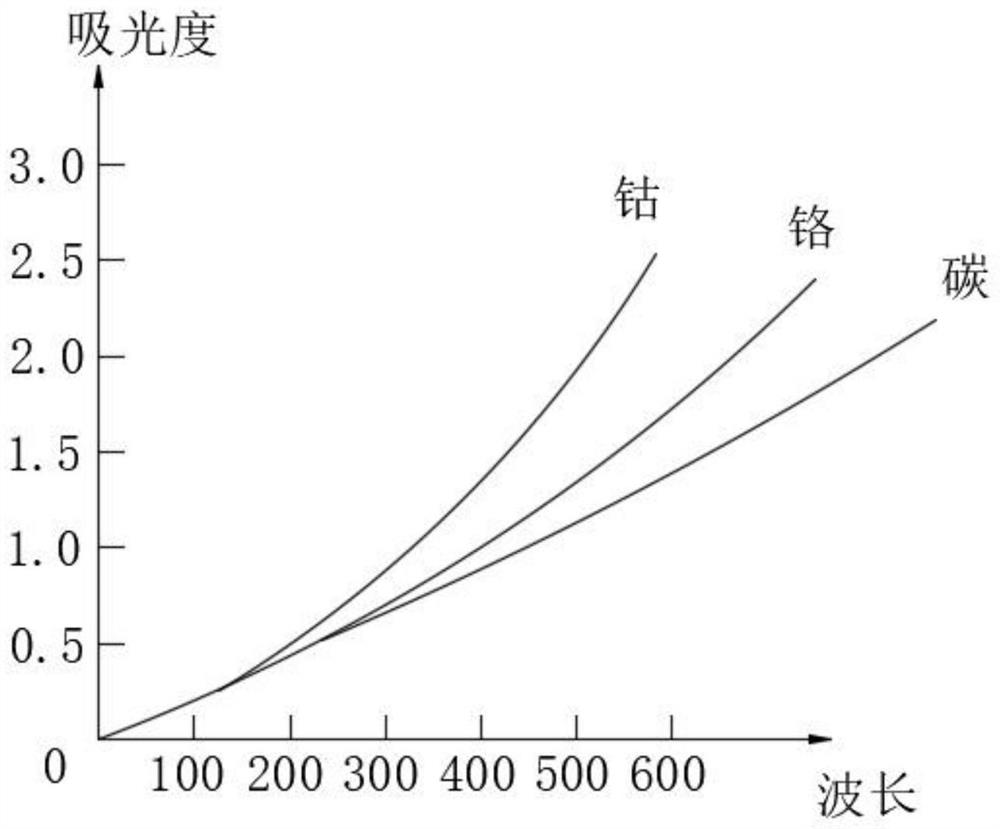

The invention relates to the technical field of metal detection, discloses a method for detecting chemical components of a metal material, and aims to solve the problems that existing detection methods are difficult to accurately measure the contents of cobalt, chromium and carbon on the metal material, whether the current contents of cobalt, chromium and carbon exceed standards cannot be known, and the existing detection methods mostly need to add HF, so that the detection efficiency is high. The method comprises the following steps: S1, drying a to-be-detected metal material in a vacuum oven at 95-115 DEG C for 1.5 hours, taking out the metal material, adding a sodium hydroxide solution into a transparent container, adding the metal material into the sodium hydroxide solution, standing for 5-10 minutes, and observing whether the sodium hydroxide solution is changed or not. According to the detection method, light absorption values and working curves are compared and analyzed one by one, the multi-level area sizes of particles with different particle sizes are counted, the actual content of cobalt, chromium and carbon is determined according to the density and distribution area of the particles with different particle sizes, and the content of cobalt, chromium and carbon on the metal material can be accurately measured.

Description

A method for detecting chemical composition of metal materials technical field [0001] The present invention relates to the technical field of metal detection, in particular to a method for detecting the chemical composition of metal materials. Background technique Metal materials generally refer to pure metals or alloys in industrial applications, and there are about 70 kinds of pure metals in nature, Among them, iron, copper, aluminum, tin, nickel, gold, silver, lead, zinc, etc. are common, and alloys often refer to two or more metals or gold It is a material that is combined with a non-metal and has metallic properties. Common alloys such as steel alloys composed of iron and carbon, copper and The alloy formed by zinc is brass, etc. After the metal material is produced, it will be coated on the metal surface with different uses due to different uses. The same chemical composition, in order to ensure normal use, it is necessary to test the chemical composition of th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N21/31G01N23/223

CPCG01N21/31G01N23/223

Inventor 杨恒范志荣胡玥郑勇军傅俊磊丁勇何卫东冀增悦王小龙陈洁马再生方军吴淳杰虞新华蔡长寿高平平陈建芬吴鑫佳林茂青

Owner 浙江方圆金属材料检测有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com