Grinding machine pollution discharge waste liquid separation treatment method

A waste liquid separation and grinding machine technology, which is applied in separation methods, sludge treatment, water/sewage treatment, etc., can solve the problem of low COD removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

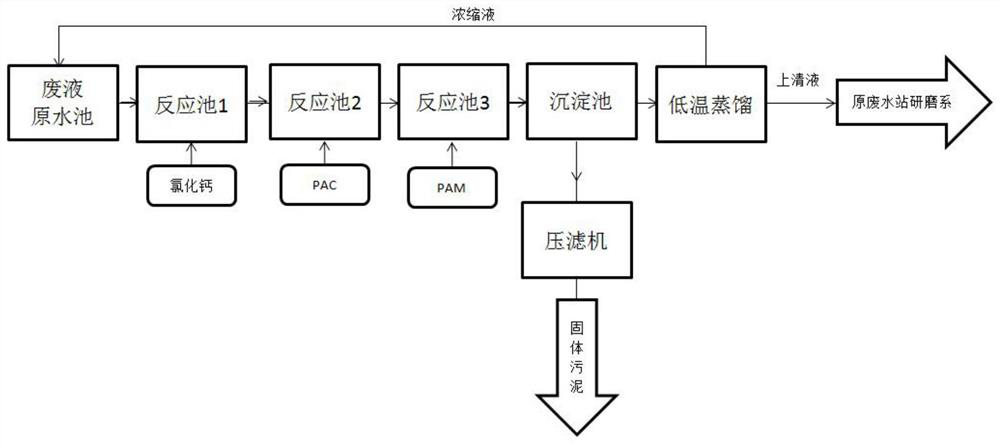

[0026] SeeFigure 1 , specific embodiment 1, a method for separating and treating the sewage waste liquid of the grinder, comprising the following steps:

[0027] Step 1: The wastewater solution in the wastewater tank is sent to the first reaction tank to add calcium chloride to adjust the PH to partial alkali;

[0028] Step 2, after entering the second reaction cell to add polyaluminum chloride;

[0029] Step 3, after entering the third reaction cell to add polyacrylamide;

[0030] Step 4, after entering the sedimentation tank, the sedimentation tank overflow into the low-temperature distillation equipment for distillation;

[0031] Step 5, distill the supernatant in the low-temperature distillation equipment, the clear liquid COD <1000, discharged into the wastewater system;

[0032] Step 6, the concentrate produced by distillation is discharged into the wastewater tank to re-enter the cycle.

[0033] This method avoids the generation of high concentration concentrate in the trad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com