PC/PBT alloy over-CTI plastic and preparation method thereof

A PBT resin and plastic technology, applied in the field of plastic preparation, can solve the problems of uneven mixing of plastic raw materials, affecting the quality of plastic preparation, reducing plastic practicability, etc., to achieve the effects of improving cooling efficiency, being suitable for popularization and use, and being convenient for granulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A PC / PBT alloy over-CTI plastic and a preparation method thereof, the formula is as follows:

[0022] The raw materials include by weight: 30 parts of PC resin, 20 parts of PBT resin, 3 parts of compatibilizer, 18 parts of wollastonite, and 29 parts of metal oxide.

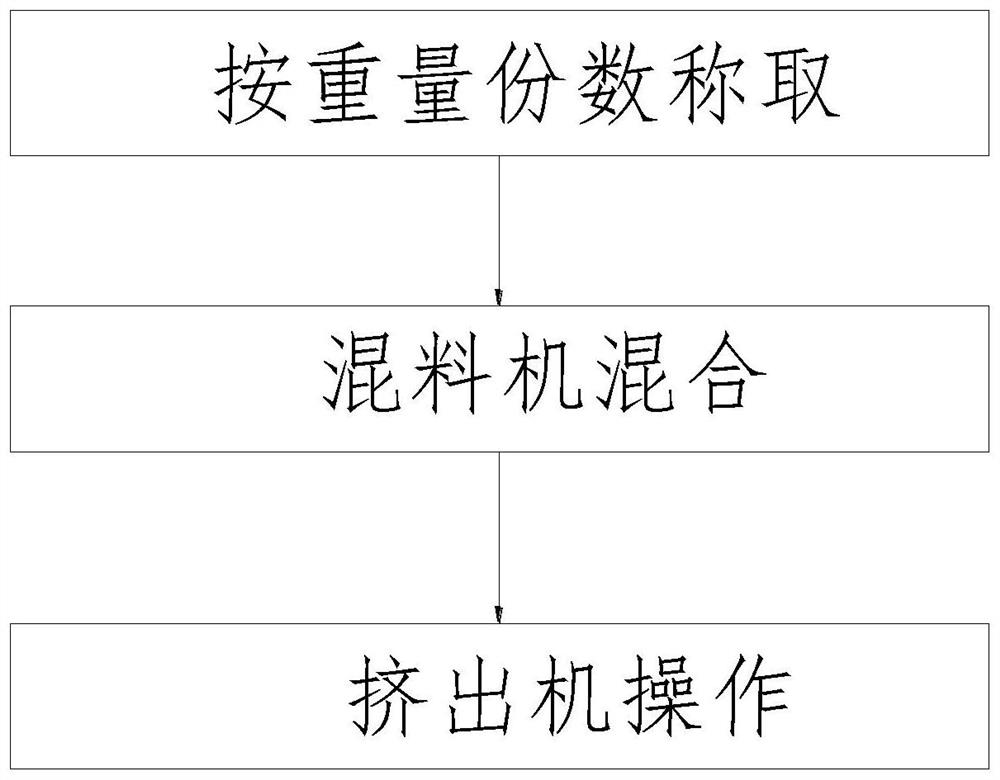

[0023] A preparation method of PC / PBT alloyed CTI plastic, the preparation method comprises the following steps:

[0024] (1) Weigh 30 parts by weight of PC resin, 20 parts of PBT resin, 3 parts of compatibilizer, 16 to 20 parts of wollastonite, and 20 to 30 parts of metal oxide, and mix them in a storage bucket to obtain a premixed material, spare;

[0025] (2) mixing in a mixer, adding the premix in step (1) to the mixer, mixing the premix in the mixer for 15 minutes, and mixing the mixture evenly and storing it in a storage tank for subsequent use;

[0026] (3) The extruder is operated, and the mixture in the storage tank in step (2) is continuously and stably added to the twin-screw extruder, melted a...

Embodiment 2

[0037] A PC / PBT alloy over-CTI plastic and a preparation method thereof, the formula is as follows:

[0038] 30 parts of PC resin, 20 parts of PBT resin, 3 parts of compatibilizer, 16 parts of wollastonite, and 21 parts of metal oxide.

[0039] A preparation method of PC / PBT alloyed CTI plastic, the preparation method comprises the following steps:

[0040](1) Weigh 30 parts by weight of PC resin, 20 parts of PBT resin, 3 parts of compatibilizer, 16 to 20 parts of wollastonite, and 20 to 30 parts of metal oxide, and mix them in a storage bucket to obtain a premixed material, spare;

[0041] (2) mixing in a mixer, adding the premix in step (1) to the mixer, mixing the premix in the mixer for 15 minutes, and mixing the mixture evenly and storing it in a storage tank for subsequent use;

[0042] (3) The extruder is operated, and the mixture in the storage tank in step (2) is continuously and stably added to the twin-screw extruder, melted and extruded, cooled and pelletized to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com