Reinforcing structure for earthing double-shell low-temperature liquid hydrocarbon storage tank

A low-temperature liquid state and reinforced structure technology, which is applied to fixed-capacity gas storage tanks, gas/liquid distribution and storage, and outer walls of container structures. The total weight of the tank, material saving, and the effect of relieving local stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The invention patent is further described below in conjunction with the accompanying drawings.

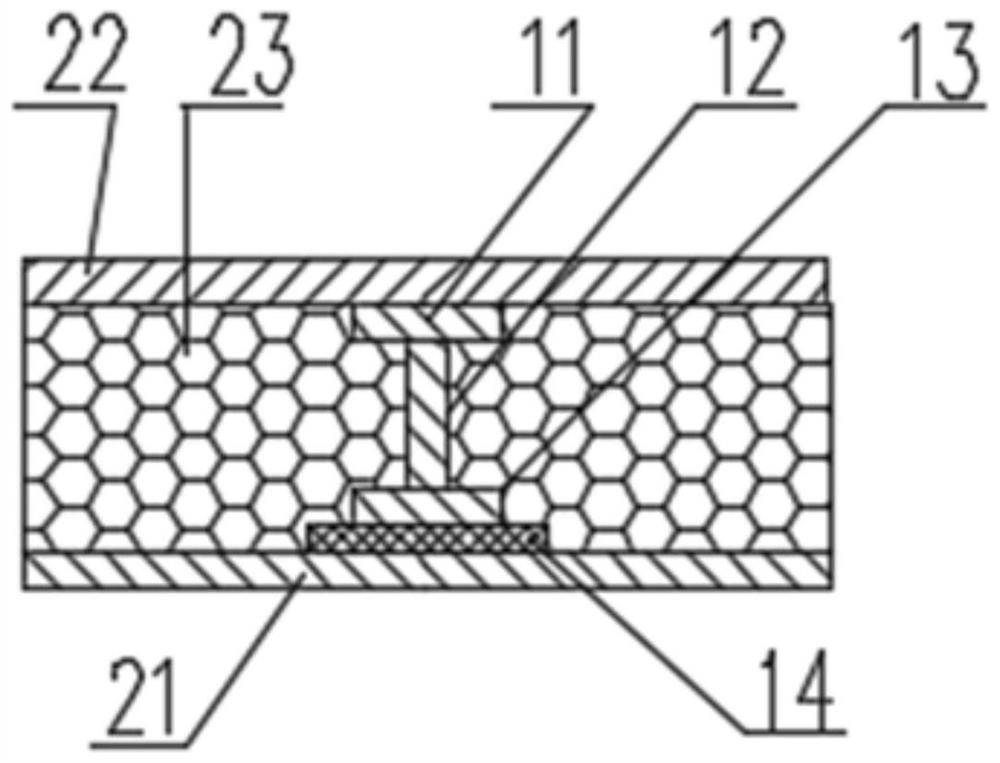

[0030] as attached figure 1 and attached figure 2 As shown, the reinforcing structure for a low-temperature liquid hydrocarbon storage tank of the present invention includes a top plate 11, a lattice member 12, a wing plate 13, a thermal insulation block 14 and the like.

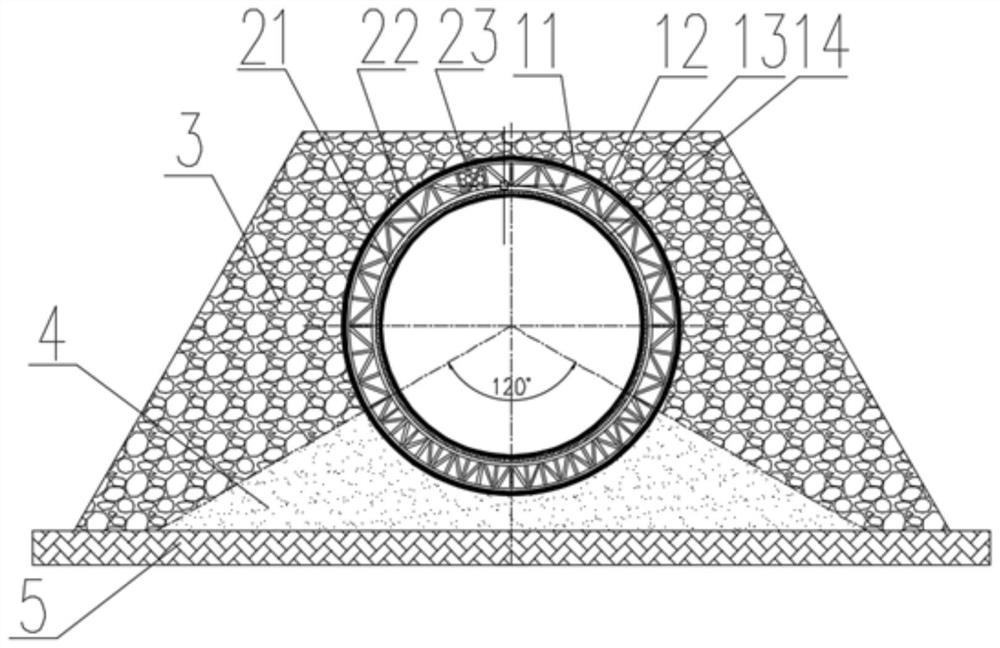

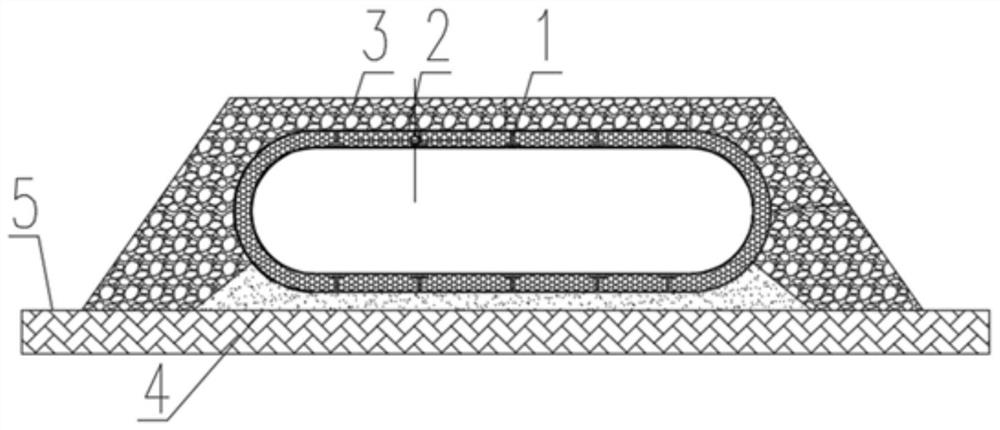

[0031] see figure 2 and 3 , the layout of the reinforcement structure. The earth-covered double-shell low-temperature liquid hydrocarbon storage tank is composed of a double-shell horizontal storage tank 2, an overburden layer 3, a continuous sand bed foundation 4, and a civil foundation 5. The upper and surrounding areas of the double-shell horizontal storage tank 2 are covered with an overburden layer 3 , and a continuous sand bed foundation 4 is arranged in the bottom 120 corners, and the continuous sand bed foundation 4 is arranged on the civil foundation 5 .

[0032] The double-shell horizontal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com