Pomace drying treatment equipment

A drying treatment and equipment technology, which is applied in the field of medical device manufacturing and pomace drying treatment equipment, can solve the problems of pomace moisture loss, slow drying speed, high energy consumption, etc., and achieve energy saving and uniform water content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The pomace drying treatment equipment of the present invention can be made of the following materials and components, and is not limited to the following materials and components, such as: microwave tubes, stirrers, grinders, filter screens, electric heaters, motors, drive shafts, etc. .

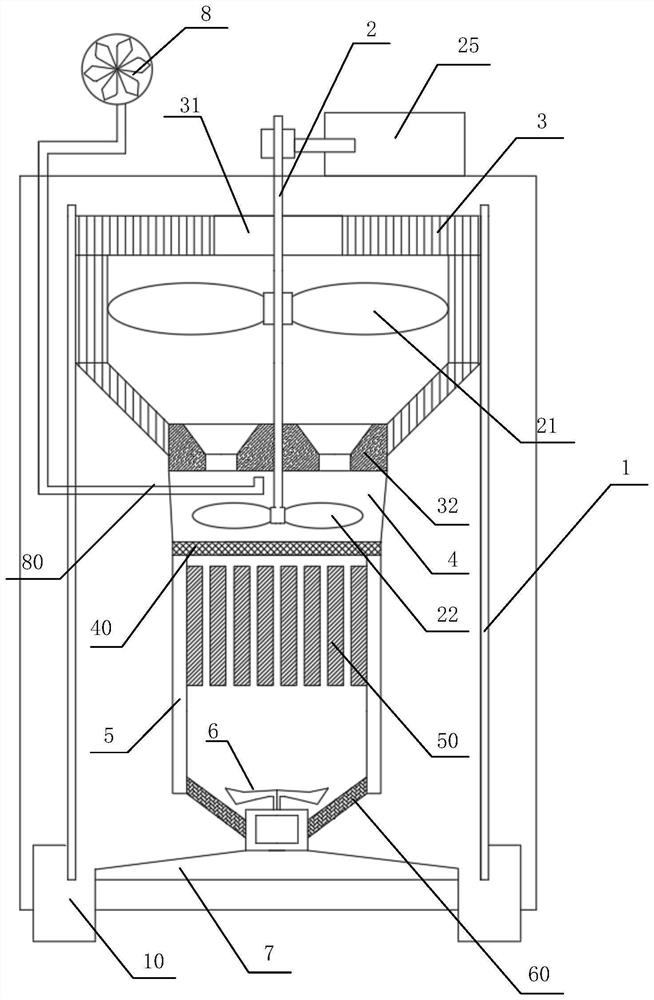

[0020] like figure 1 Shown is the side structure diagram of the pomace drying treatment equipment of the embodiment of the present invention; and with reference to figure 2 .

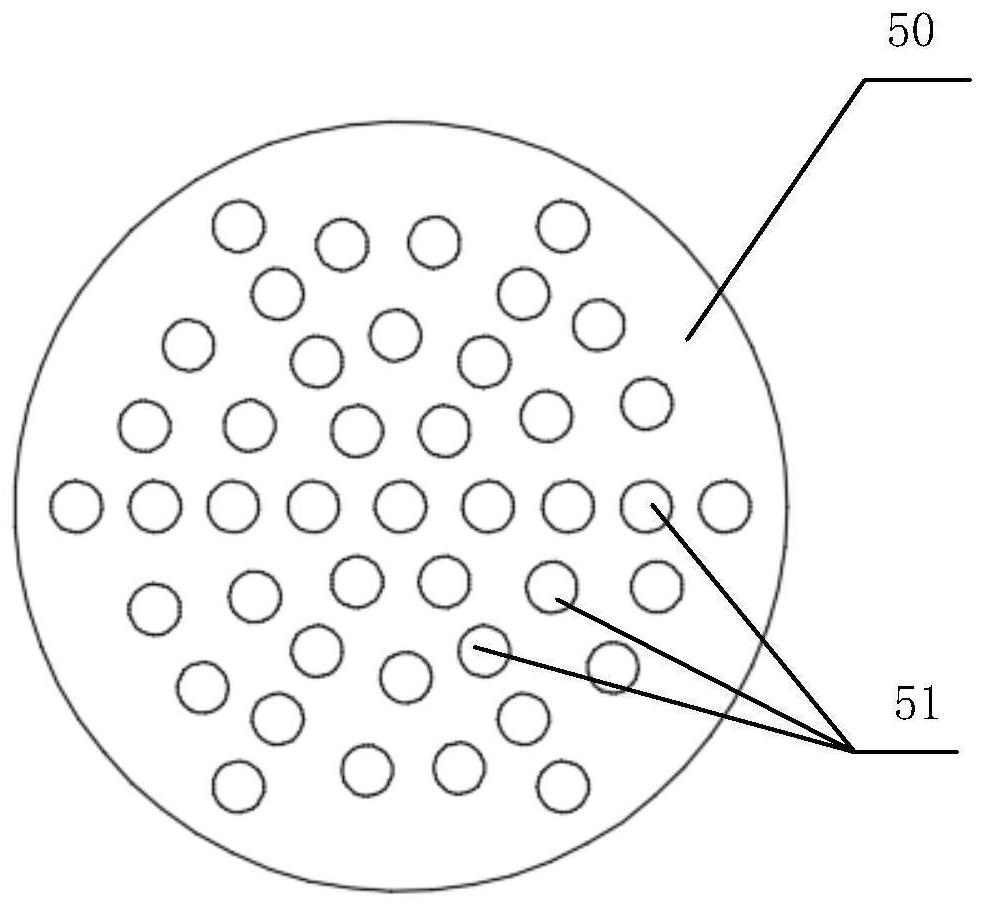

[0021] The pomace drying processing equipment in this embodiment includes: a casing 1 , a microwave chamber 3 , an air compressor 8 , a heater 50 and a grinding chamber 5 ; the microwave chamber 3 is connected to the grinding chamber 5 through the heater 50 , the three are sequentially fixed in the casing 1 from top to bottom; the air compressor 8 has an air outlet pipe 80 with an exhaust port; the air compressor 8 is used to introduce compressed air, so that the high-pressure airflow Turn the heated pomace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com