Gas-liquid mixed recovery type redundant material flushing device and gas-liquid mixed recovery type redundant material flushing method

A gas-liquid mixing and flushing device technology, applied in the aerospace field, can solve the problems that the system cannot be seriously damaged, the momentum is small, and the excess material is limited, and the flushing device is convenient, improves the integration, and simplifies the complexity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

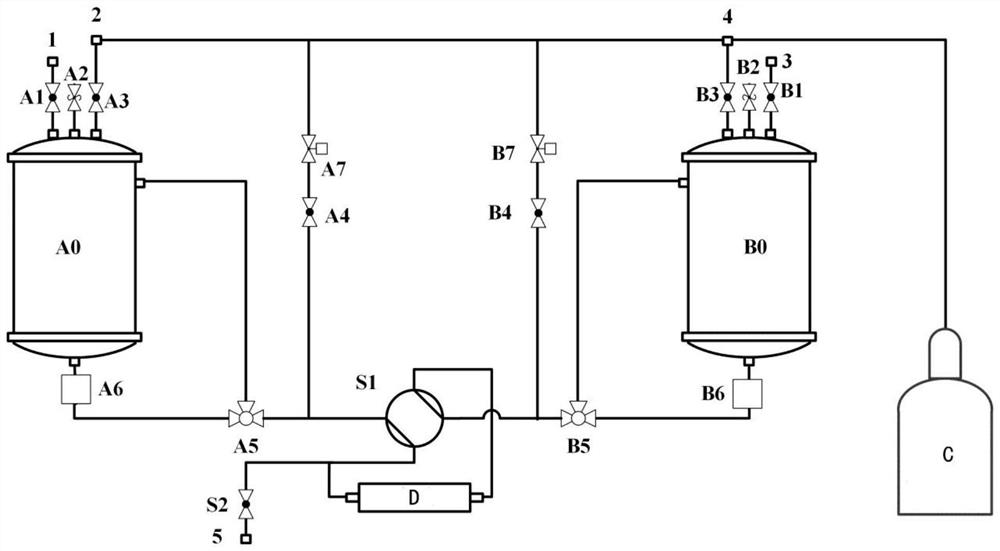

[0041] like Figure 1 to Figure 7As shown in the figure, a gas-liquid mixed recovery type excess washing device of this embodiment includes a first liquid storage tank A0, a second liquid storage tank B0, a gas storage tank C, a four-way valve S1, a first gas branch and The second gas branch, the gas storage tank C is respectively connected with the first gas inlet at the top of the first liquid storage tank A0 and the second gas inlet at the top of the second liquid storage tank B0 through the gas pipeline; The first liquid outlet and the first liquid inlet of the liquid tank A0 are connected to the second liquid outlet and the second liquid inlet of the second liquid storage tank B0 through a flushing pipeline, and the flushing pipeline is equipped with a spool. Valve S1, the two valve ports of the four-way valve S1 are connected to the flushing pipeline, and the other two valve ports of the four-way valve S1 are connected to the product pipeline, and the product pipeline is...

Embodiment 2

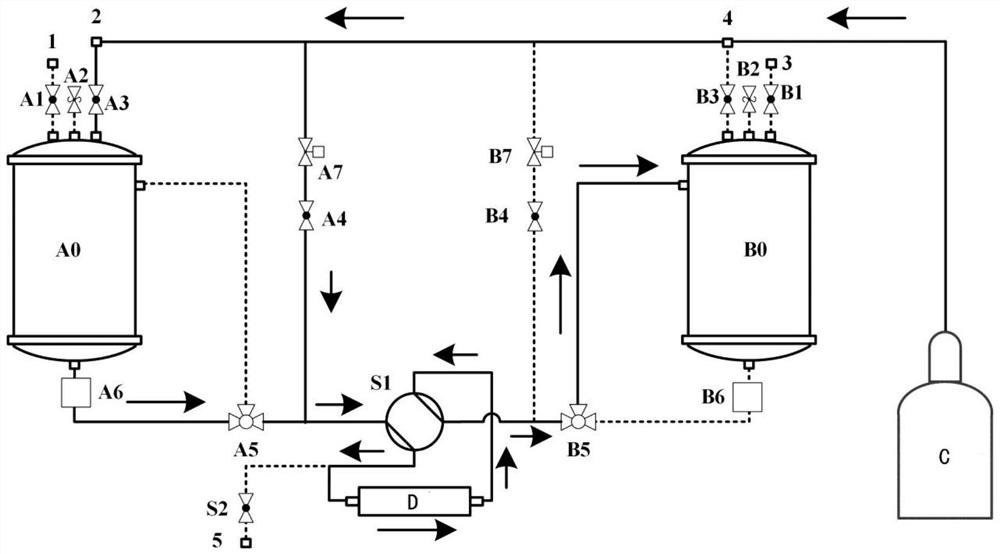

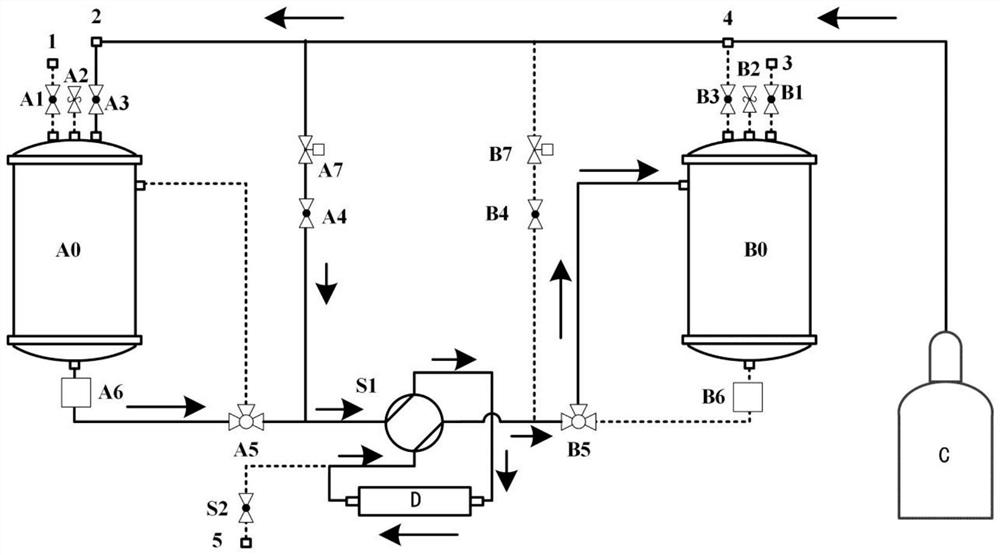

[0053] A gas-liquid mixed recovery method for flushing excess matter in this embodiment, such as Figure 1 to Figure 7 As shown, the above-mentioned gas-liquid mixed recovery type surplus flushing device is used to realize, including:

[0054] The first liquid storage tank A0 is in the forward flushing mode, the gas storage tank C is connected to the top of the first liquid storage tank A0 through the gas pipeline, and the first liquid outlet at the bottom of the first liquid storage tank A0 is passed through the four-way valve S1 It is connected with the inlet end of the product pipeline, the first gas branch is connected, and then the outlet end of the product pipeline is connected with the second liquid inlet of the second liquid storage tank B0 through the four-way valve S1 to form the first gas pipeline. A forward flushing system; use the gas storage tank C to transport gas to the top of the first liquid storage tank A0 and the first gas branch, and the gas entering the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com