Pot body dull polish device

A pot body and sanding technology, which is applied to grinding drive devices, grinding/polishing safety devices, combined devices, etc., can solve the problems of low dust treatment efficiency, and achieve the advantages of increased air intake, high treatment efficiency and increased sedimentation efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The technical scheme adopted by the present invention is as follows:

[0035] The invention discloses a pot body sanding device, comprising: a support seat, a movable seat and a dust suction device; a first drive device is installed in the support seat, and a rotating seat is installed on the output shaft of the first drive device, and the The rotating seat is used to place the pot body; the movable seat is equipped with a second driving device; the output shaft of the second driving device is equipped with a grinding disc; The outer cover of the suction hood is outside the abrasive disc, one end of the suction pipe is connected to the suction hood, and the other end is connected to the dust collecting mechanism; the suction pipe is also equipped with a spray device, and the spray device is used to settle dust. The bottom of the movable seat is equipped with a third driving device, and the third driving device is used to drive the movable seat to move laterally. A tele...

Embodiment 2

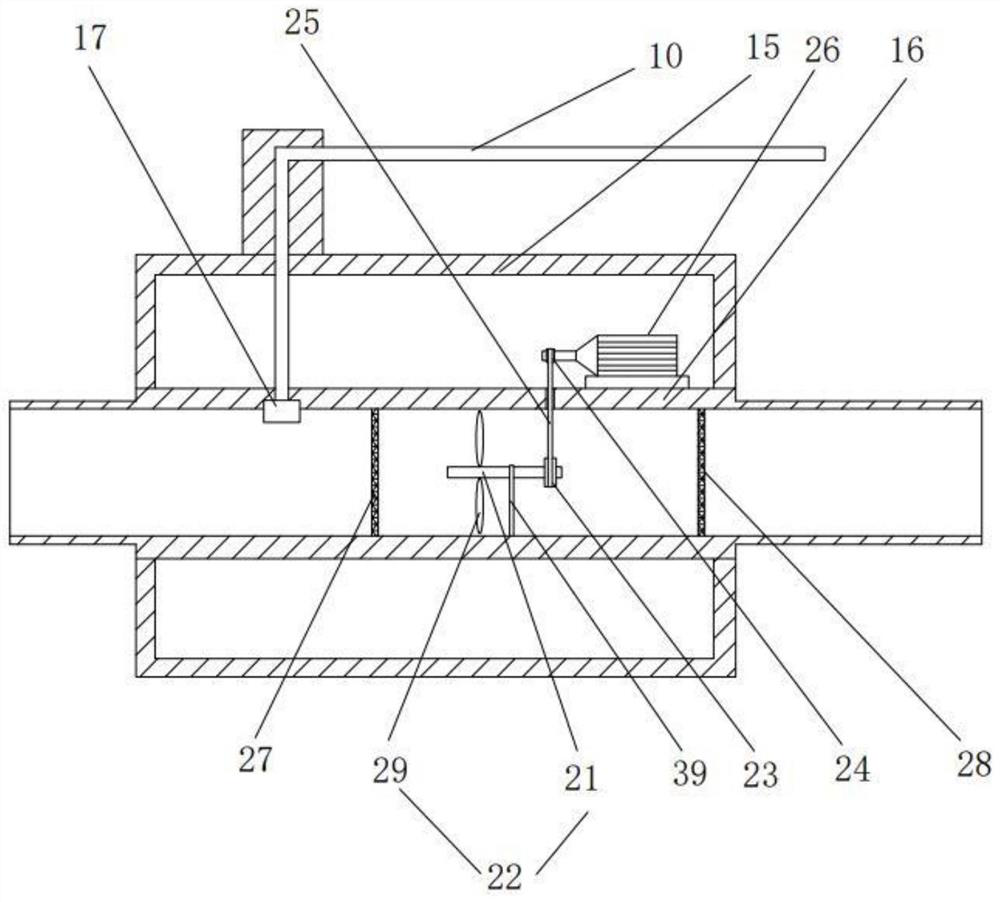

[0038] like figure 1 , figure 2 and image 3 As shown, the present invention discloses a pot body sanding device, comprising: a support seat, a movable seat and a dust suction device; a first drive device is installed in the support seat, and a rotation seat is installed on the output shaft of the first drive device , the rotating seat is used to place the pot body; the movable seat is equipped with a second driving device; the output shaft of the second driving device is equipped with a grinding disc; Collection mechanism, the dust hood is covered outside the sanding disc, one end of the suction pipe is connected to the dust hood, and the other end is connected to the dust collection mechanism 10; the suction pipe is also equipped with a spray device, and the spray device is used for sedimentation dust. The bottom of the movable seat is equipped with a third driving device, and the third driving device is used to drive the movable seat to move laterally. A telescopic pip...

Embodiment 3

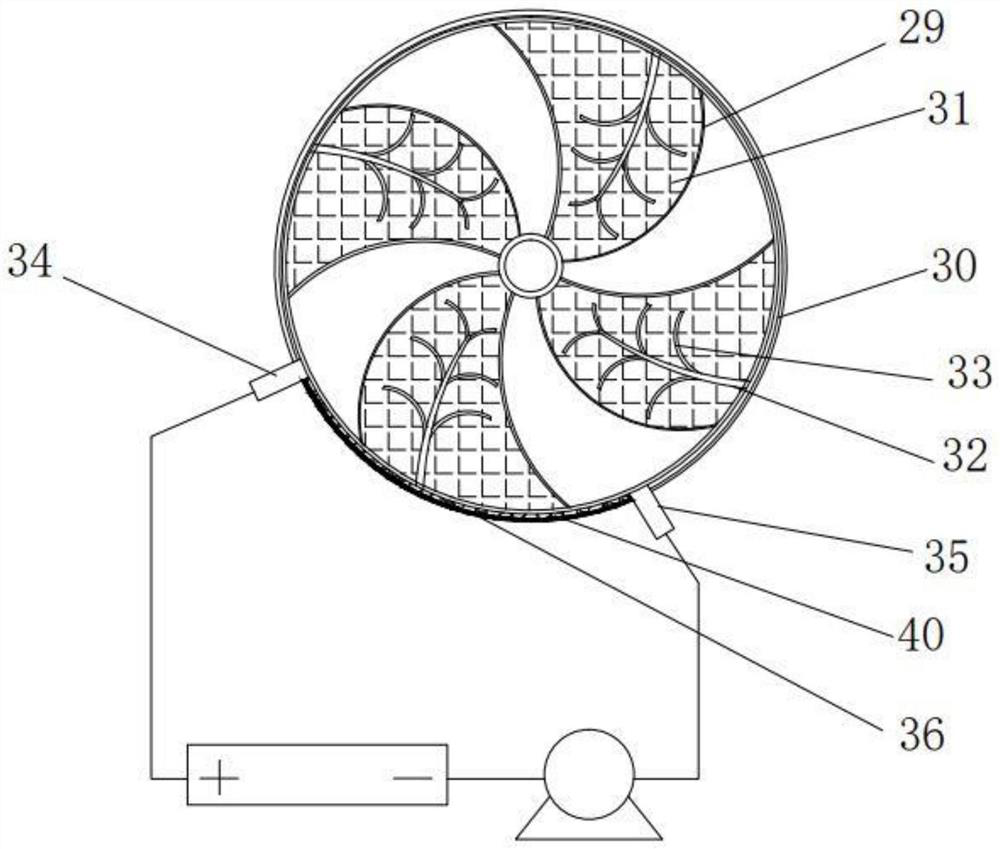

[0045] The difference between this embodiment 3 and embodiment 2 is that, as Figure 4 and Figure 5 As shown, a current meter 37 is installed on the circuit between the second electrical contact piece and the mobile power supply, and the current meter is connected to a control unit 38, and the control unit is used to control the operation of the fourth driving device.

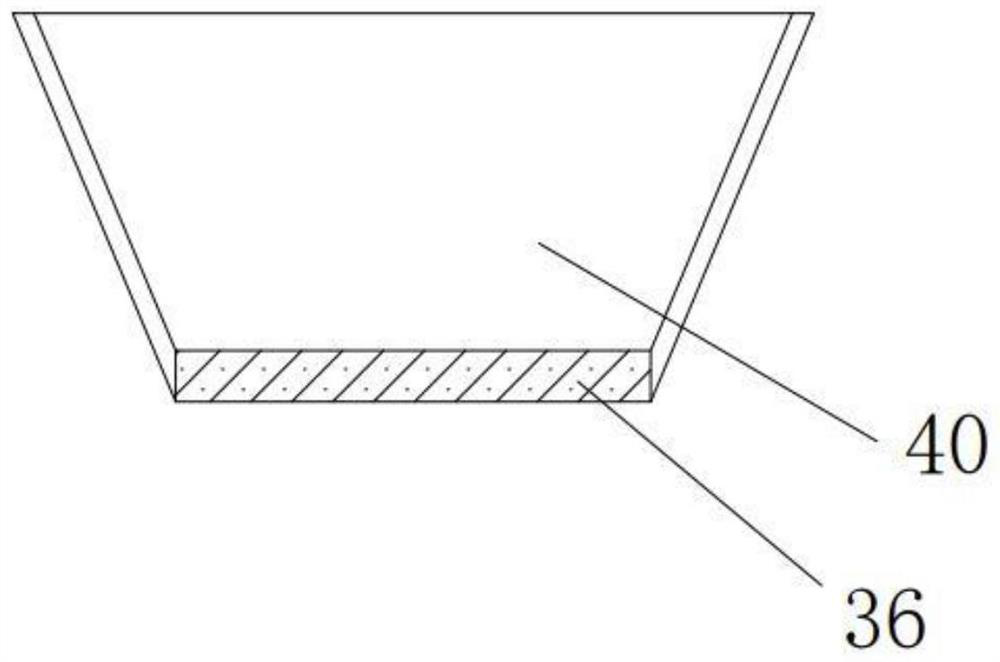

[0046] When this embodiment is implemented, part of the water droplets are squeezed into the potassium chloride wafer to dissolve, so that the first electrical contact piece and the second electrical contact piece are directly connected, so that the first electrical contact piece, the second electrical contact piece, and the heating resistor piece are , the mobile power supply closes the circuit; at this time, due to the increase of the energization area, the current in the circuit decreases, so that the current in the galvanometer increases, and the control unit controls the output power of the fourth drive d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com