Plant fiber modified ABS (Acrylonitrile Butadiene Styrene) material and refrigerator decoration strip prepared from same

A technology of ABS material and plant fiber, applied in the field of refrigerator accessories, can solve the problems of monotonous appearance of decorative strips, and achieve the effect of improving interior decoration effect, high environmental protection and strong process operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

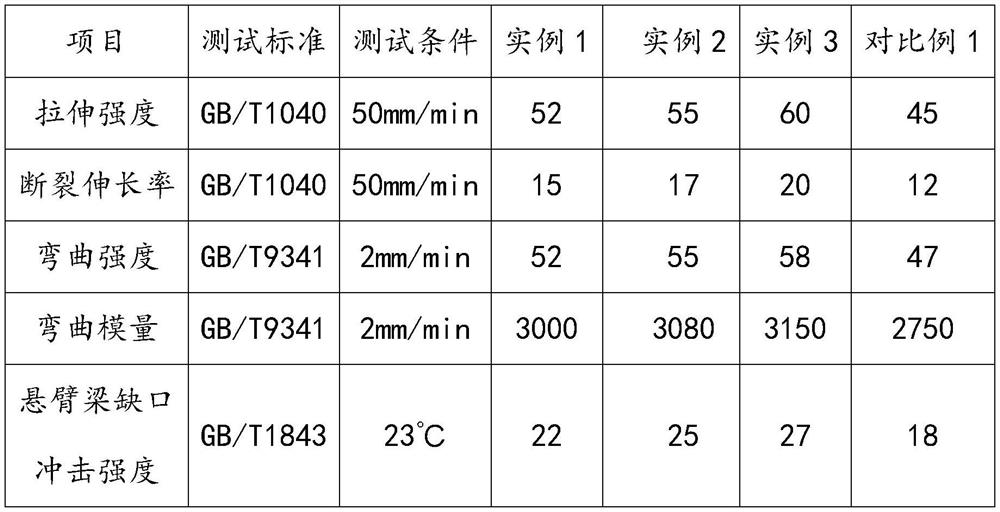

Examples

Embodiment example 1

[0020] A plant fiber modified ABS material, comprising: 60g of ABS resin, 30g of wheat straw fiber, 15g of ABS grafted maleic anhydride, 1g of stabilizer, 2g of lubricant, and 2g of pigment.

[0021] Preparation:

[0022] Take various raw materials according to the formula, after fully mixing, add them into the twin-screw granulator barrel, set the main engine speed to 250r / min, and set the extrusion temperature to 180-200℃, and granulate to obtain plant fiber modified ABS pellets; The above-mentioned modified ABS pellets are added into a single-screw decorative strip extruder, the extruder is set at 190-210° C., and after extrusion, the decorative strips for refrigerators are obtained by cooling and cutting.

Embodiment example 2

[0024] A plant fiber modified ABS material, comprising: 70g of ABS resin, 20g of corn stover fiber, 7g of styrene grafted maleic anhydride, 1g of stabilizer, 1g of lubricant, and 1g of pigment.

[0025] Preparation method: same as Example 1.

[0026] A plant fiber modified ABS material, comprising: 72g of ABS resin, 15g of sawdust fiber, 10g of styrene grafted maleic anhydride, 1g of stabilizer, 1g of lubricant, and 1g of pigment.

[0027] Preparation method: same as Example 1.

[0028] In the above-mentioned Examples 1-3, the particle size of the adopted wheat straw fiber, corn straw fiber and sawdust fiber is 32-35 meshes. At the same time, the ABS resin is acrylonitrile-butadiene-styrene terpolymer, and the melt index is 20-35g / min under the test condition of 220℃ / 10kg.

[0029] And in the above, the stabilizer is composed of 1:1 antioxidant and light stabilizer; the antioxidant is hindered phenolic antioxidant CHEMNOX 1010; the light stabilizer is Cyasorb UV23346. The l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com