High-focusing metasurface lens

A metasurface and lens technology, applied in the field of metasurface, can solve the problems of high machining accuracy, high machining difficulty, and large longitudinal size, and achieves the effect of solving high machining accuracy requirements, compact structure, and large longitudinal size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

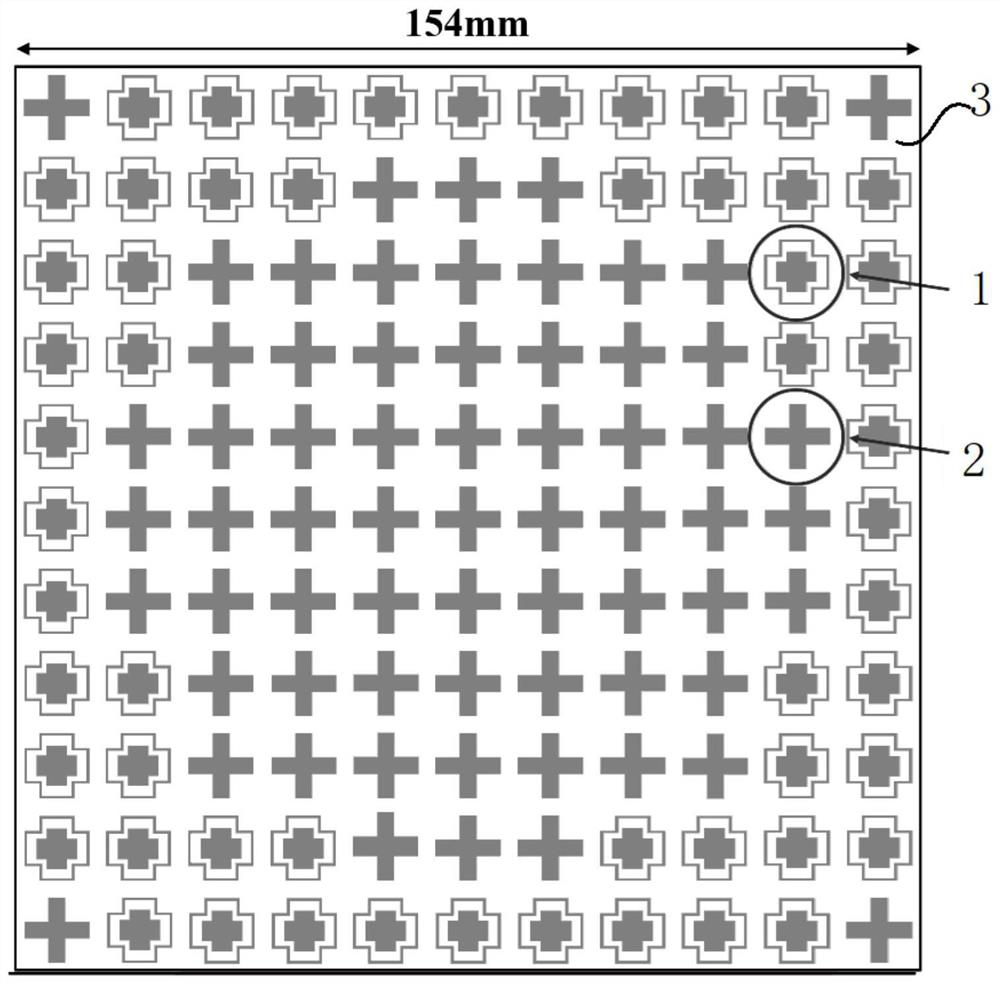

[0032] The high-focusing meta-surface lens in this embodiment is an ultra-thin focusing meta-surface lens operating at 10 GHz. The dielectric substrate adopts F4BM, the dielectric constant of F4BM is 4.3, the loss tangent is 0.0025, and the thickness is 2.8mm. The same cross-shaped metal lines are printed on both sides of the dielectric substrate, and the entire unit is a single-layer structure.

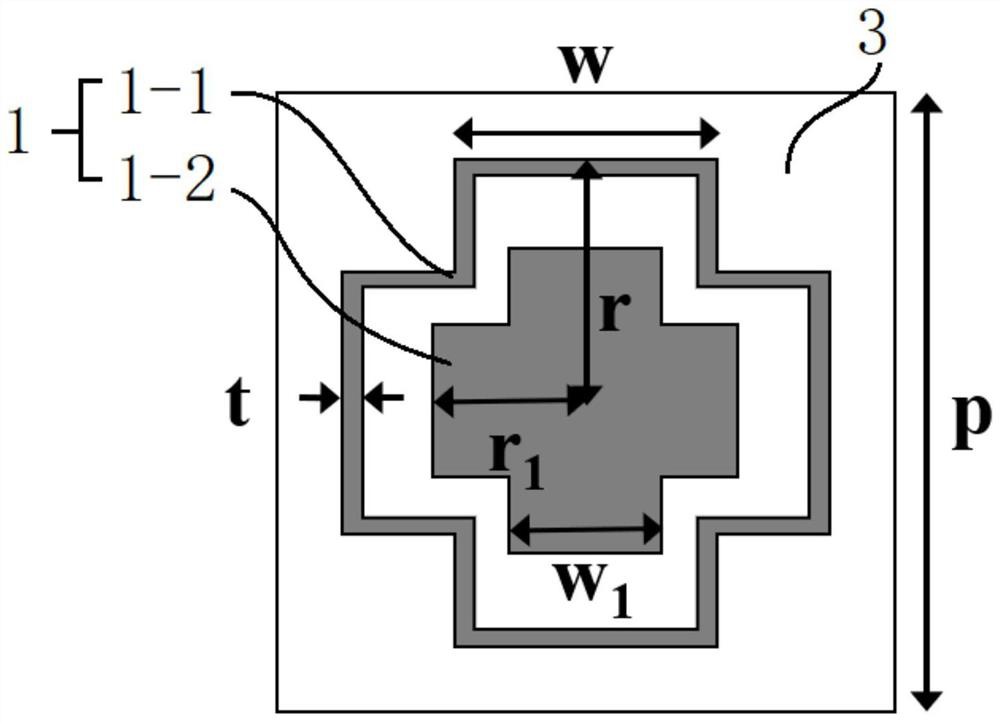

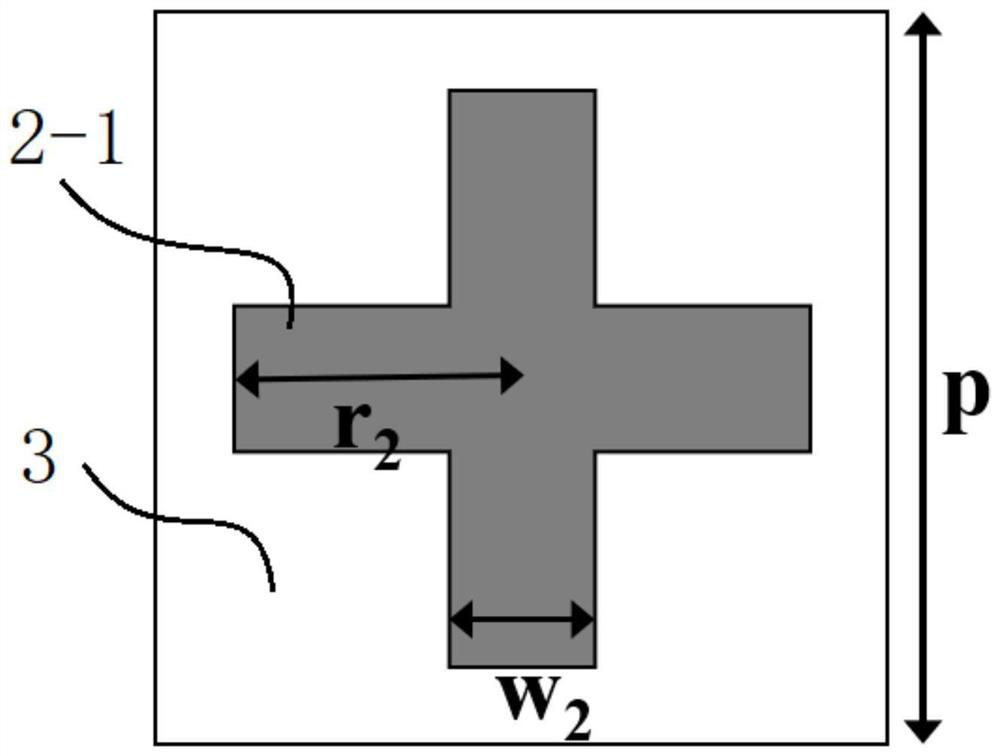

[0033] The lens unit includes two types of units: lens unit EA1 and lens unit EB2. The side lengths of the lens unit EA1 and the lens unit EB2 are both p. The same metal pattern of the lens unit EA1 is printed on the front and back sides of the dielectric substrate, and the structure of the lens unit EA1 includes a hollow cross ring 1-1 and a first solid cross 1-2. The width of the hollow cross ring 1-1 is t, the length of the ring arm is r, and the arm width is w; the arm length of the solid cross 1-2 inside the hollow cross ring 1-1 is r 1 , the arm width is w 1 . The same met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com