Battery performance prediction

A battery performance and battery technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve problems such as taking a long time, logical planning of test bench capacity, and long development time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

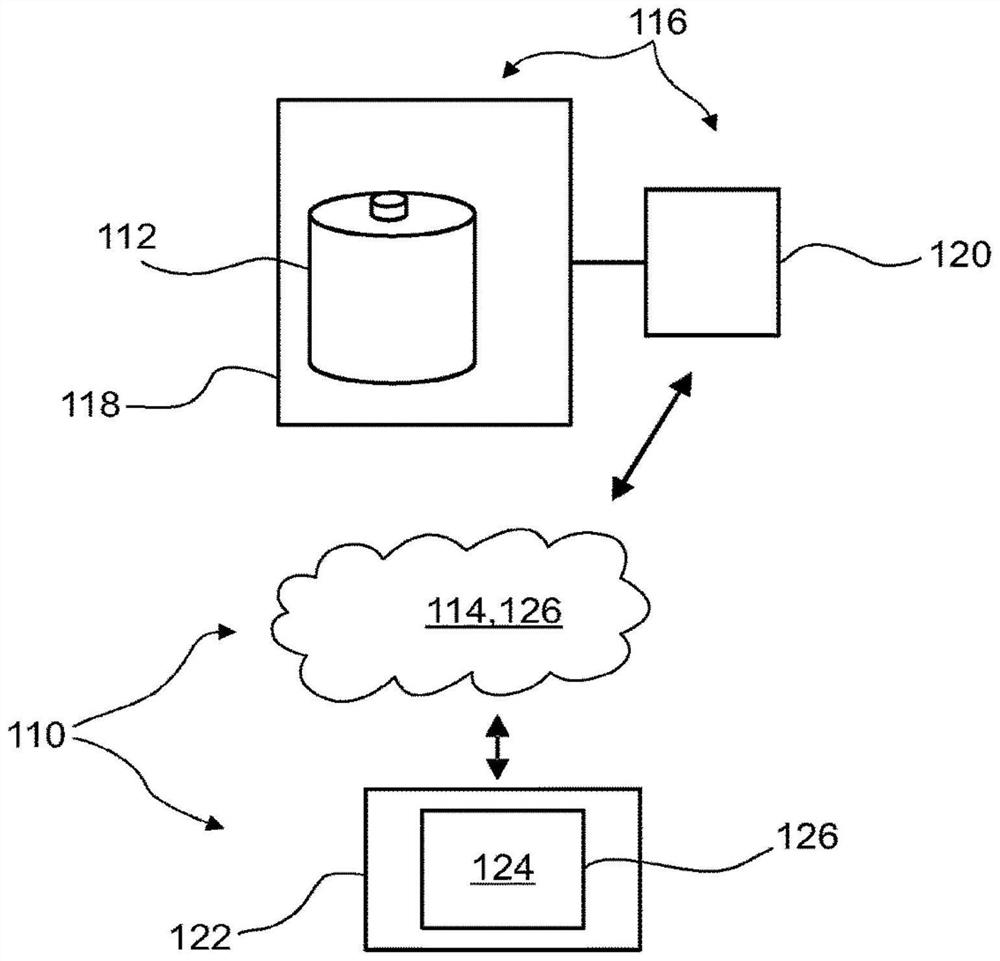

[0131] figure 1 An embodiment of a testing system 110 for determining battery performance during development of a battery configuration under test is highly illustrative. An exemplary battery 112 is shown. The battery 112 may be a rechargeable battery. The battery 112 may be selected from the group consisting of: lithium ion battery (Li-Ion), nickel cadmium battery (Ni-Cd), nickel metal hydride battery (Ni-MH). For example, the battery may include at least one cathode material selected from the group consisting of LiCoO2 (lithium cobalt oxide), LiNixMnyCozO2 (lithium nickel manganese cobalt oxide), and LiFePO4 (lithium iron phosphate). For example, the cell may include at least one anode material selected from the group consisting of graphite, silicon. For example, the battery may contain at least one electrolyte selected from the group consisting of LiPF6, LiBF4, or LiClO4 in an organic solvent such as ethylene carbonate, dimethyl carbonate, and diethyl carbonate.

[0132...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com