Fruit tree pollination device for kiwi fruits

A pollination device and kiwifruit technology, applied in the application, plant genetic improvement, agriculture and other directions, can solve the problems of difficult kiwifruit style spraying, low spraying efficiency, artificial height limitation, etc., to solve the problem of uncontrollable grant amount, improve pollination efficiency, guarantee The effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

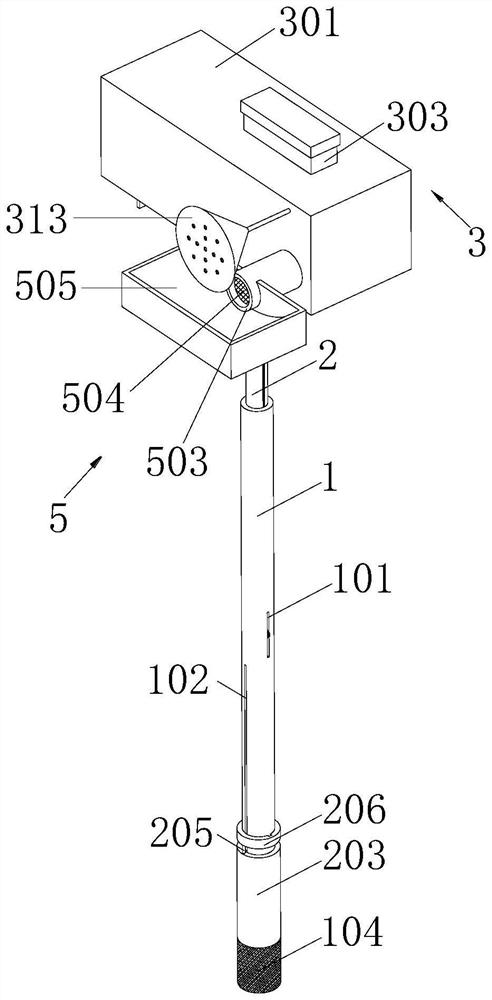

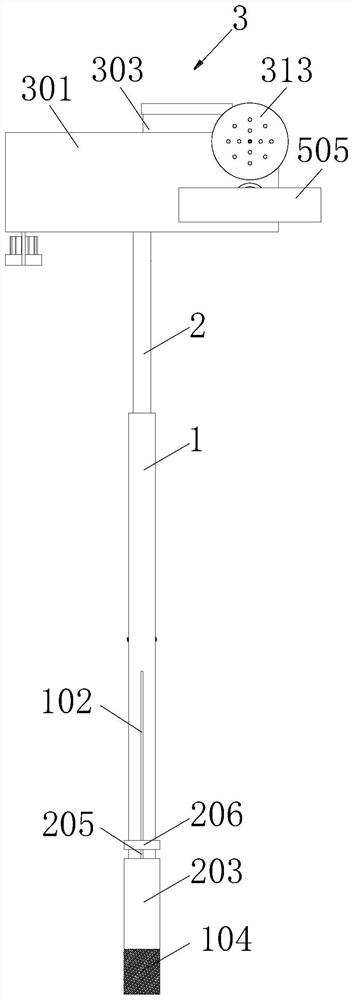

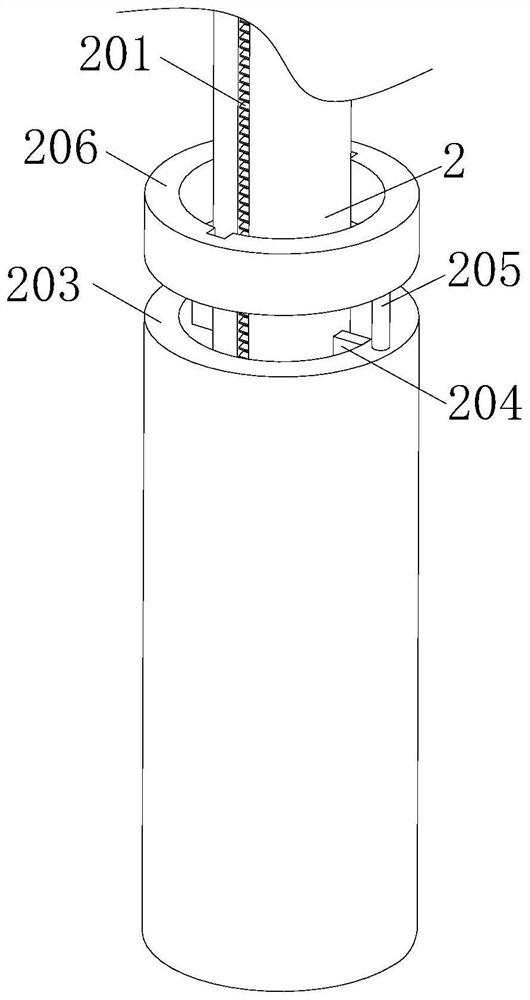

[0029] Example 1, please refer to Figure 1-6 , a fruit tree pollination device for kiwifruit, comprising a sliding cylinder 1 and a No. 1 strip hole 101 symmetrically opened at the left and right ends of the outer wall of the sliding cylinder 1, the No. 1 strip hole 101 is communicated with the interior of the sliding cylinder 1, and the outer wall of the sliding cylinder 1 And located below the No. 1 strip hole 101 is symmetrically opened with a No. 2 strip hole 102, the No. 1 strip hole 101 and the No. 2 strip hole 102 are arranged in a cross-shaped array along the outer wall of the sliding cylinder 1. A fixed rod 103 is symmetrically arranged at the bottom end of the rod 101 corresponding to the position of the No. 1 strip hole 101. The bottom ends of the two fixed rods 103 are fixedly connected with a handle 104. The diameter of the handle 104 is larger than the outer diameter of the sliding cylinder 1. The outer wall of the handle 104 Covered with a non-slip film, a tele...

Embodiment 2

[0031] Example 2, please refer to Figure 1-2 And 7-10, on the basis of Embodiment 1, the top of the telescopic rod 2 is provided with a screeding mechanism 3, and the screeding mechanism 3 includes a storage box 301 fixedly connected to the top of the telescopic rod 2, the front and rear of the inner wall of the storage box 301 A partition 302 is fixedly connected between the two ends, the top of the storage box 301 is provided with a powder injection port 303, and a bottom plate 304 is connected between one side of the partition 302 and the inner wall of the storage box 301. A side plate 305 is symmetrically arranged on the side of the end and away from the side plate 302, and there is a gap between the two side plates 305. 306 is located between the two side plates 305 and is not in contact with the side plates 305. The top end of the inner wall of the storage box 301 is provided with a scraper 307. There is a gap between the bottom end of the scraper 307 and the top of the...

Embodiment 3

[0033] Example three, please refer to Figure 7-8 , on the basis of the second embodiment, the inside of the storage box 301 is provided with a spraying mechanism 4, and the spraying mechanism 4 includes a piston plate 401 that is slidably fitted inside the storage box 301 and is located on one side of the partition 302. The top corresponding to the position between the partition plate 302 and the piston plate 401 is provided with an air inlet, the side wall of the piston plate 401 is provided with an air intake pipe 402, and the end of the air intake pipe 402 away from the piston plate 401 sequentially penetrates the side wall of the partition plate 302 and the At the rear end of the storage box 301, a first check valve 403 is provided at the end of the intake pipe 402 close to the piston plate 401, and an exhaust hole is provided on the side wall of the partition plate 302 and above the intake pipe 402. A first exhaust pipe 404 is disposed on the side of the wall close to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com