Spraying system and method for water-washing ammonia gas for preparing synthetic ammonia

A spray system, a technology for synthesizing ammonia, applied in the directions of ammonia preparation/separation, separation methods, chemical instruments and methods, etc., can solve problems such as blockage of spray equipment, no water spraying, and inability to remove ammonia from process gas, achieving increased The contact area, the effect of improving the removal effect, and ensuring the success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The embodiments of the present invention are described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered by the claims.

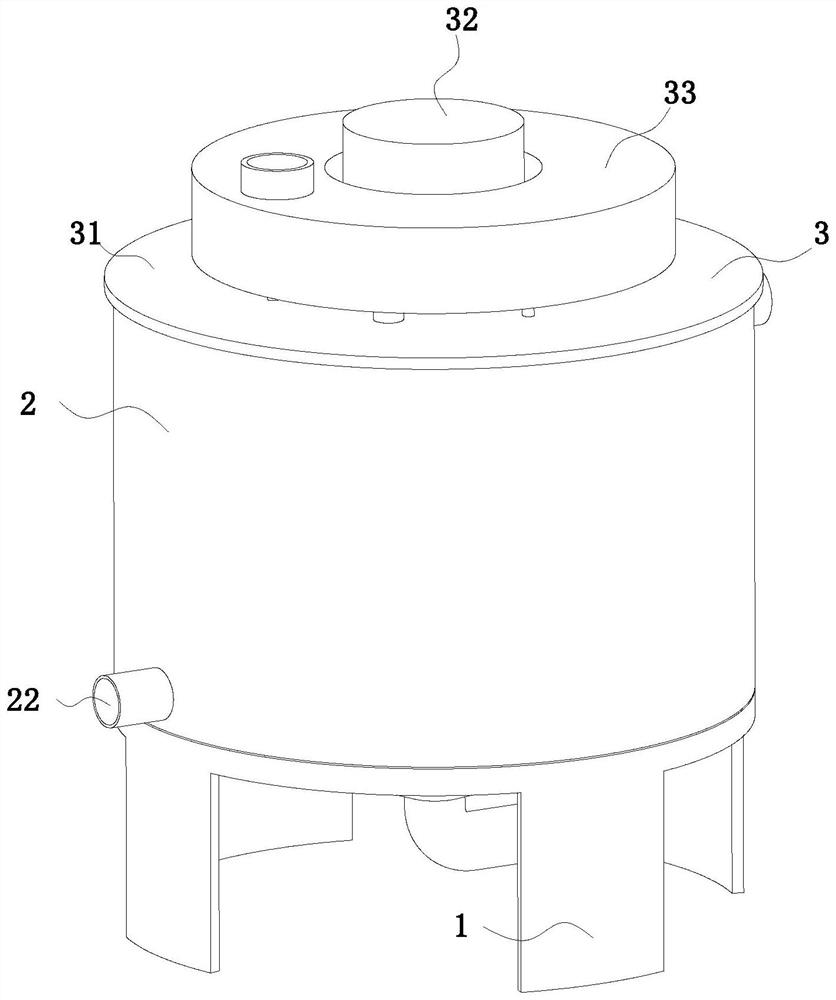

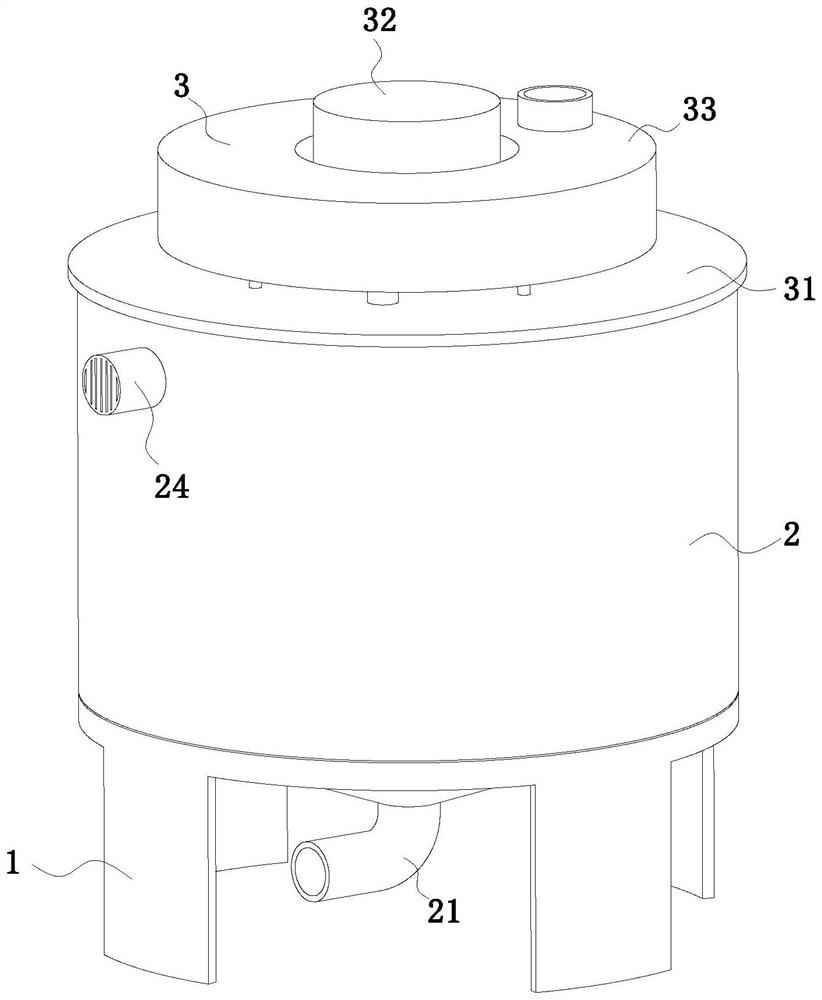

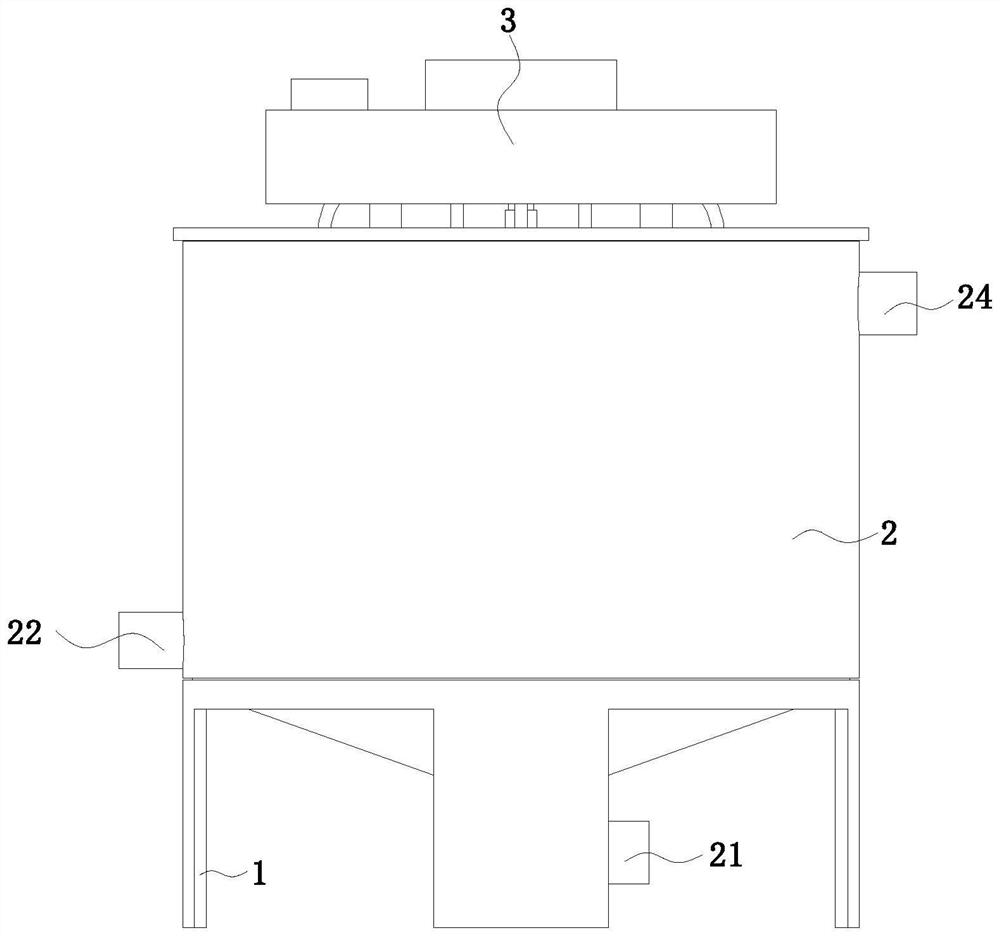

[0033] see Figure 1-Figure 3 , a synthetic ammonia preparation water washing ammonia spray system, including a support frame 1, a spray bucket 2 and a spray device 3, the support frame 1 is installed with a spray bucket 2, and the upper end of the spray bucket 2 is plugged with a sprayer device 3.

[0034] see Figure 4 , the spray device 3 includes a placement plate 31 that is inserted into the upper end of the spray bucket 2, the upper end of the placement plate 31 is installed with a drive motor 32 through a support column, and the outer side of the drive motor 32 is provided with a water inlet frame 33 in a ring structure , the water inlet frame 33 is installed on the upper end of the placing plate 31 through the installation rod, the lower en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com