Quantitative proportioning and stirring device for lubricating rubber cement

A stirring device and mortar technology, which is applied to mixers with rotating stirring devices, mixer accessories, transportation and packaging, etc., can solve the problems of inability to mix at different levels, poor molding effect of lubricating mortar, and uneven distribution ratio of lubricating mortar components. The first-class problem, to achieve the effect of improving the use effect and promoting the mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

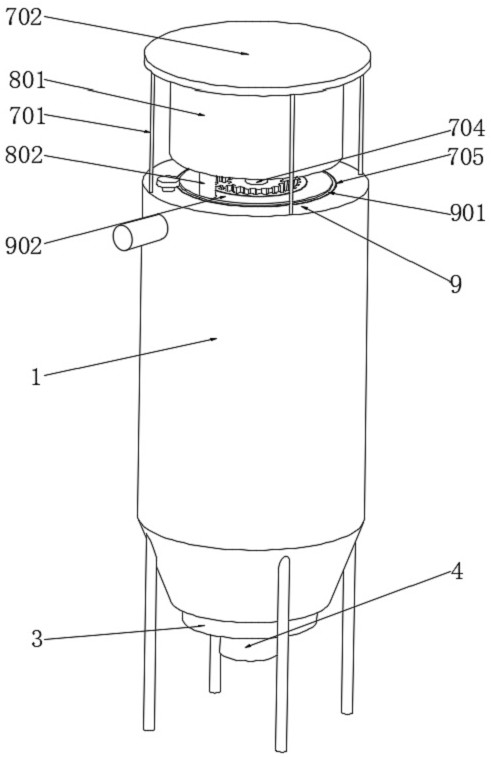

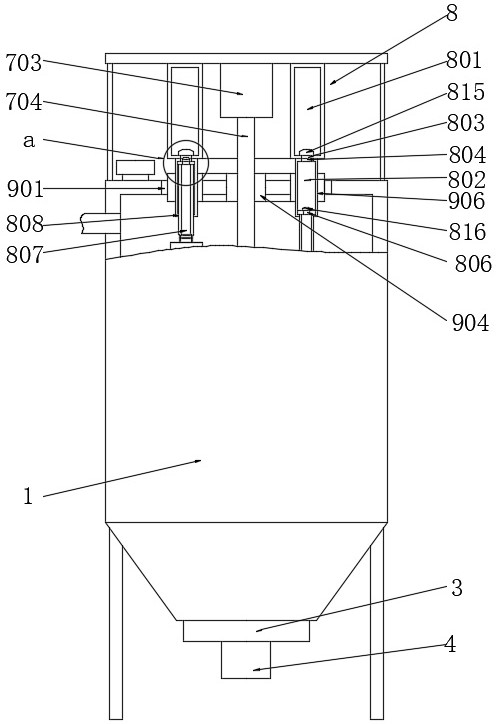

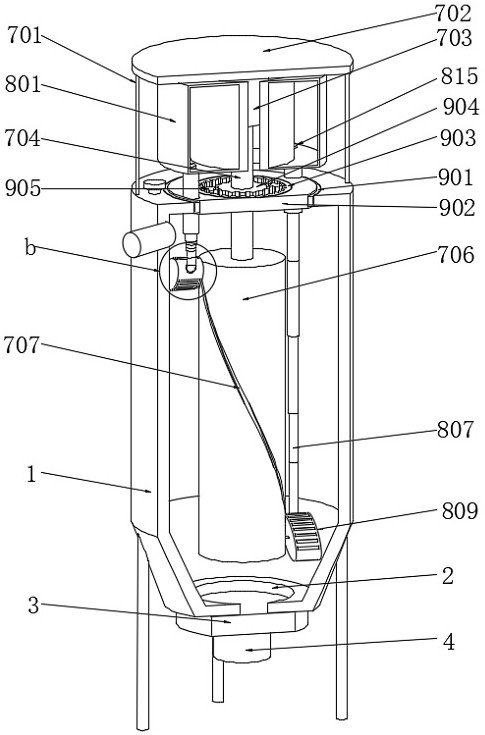

[0040] Example: as Figure 1-Figure 12 As shown, the present invention provides the following technical solutions: a lubricating mortar quantitative proportioning stirring device, the lubricating mortar quantitative proportioning stirring device comprises a tank body 1, and a liquid outlet 2 is opened at the bottom of the tank body 1, so the A liquid discharge valve 3 is fixedly installed on the liquid outlet 2, a liquid discharge pipe 4 is fixedly connected to the liquid discharge valve 3, and a liquid inlet 5 is opened on the tank body 1, and the liquid inlet 5 is fixed inside. A liquid inlet pipe 6 is connected, and a stirring component 7 and a quantitative proportioning component 8 are installed on the tank body 1. The stirring component 7 is matched with the quantitative proportioning component 8, and the quantitative proportioning component 8 is driven by the stirring component 7. During operation, when preparing the lubricating glue, the raw liquid is transported into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com