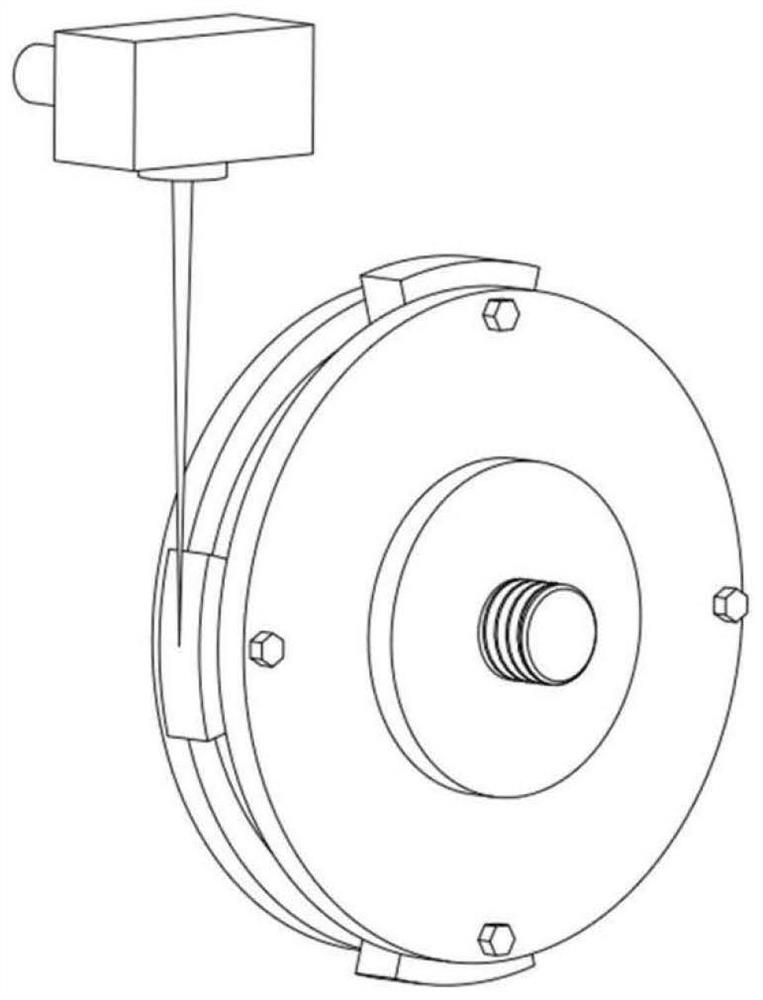

Forming grinding wheel laser shaping track planning method

A laser shaping and trajectory planning technology, applied in laser welding equipment, grinding/polishing equipment, abrasive surface adjustment devices, etc., can solve the problems of laser beam unable to remove material, laser beam idling, reduction of shaping efficiency, etc. The effect of laser spot overlap rate and scanning track line overlap, improving shaping efficiency and shortening laser processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

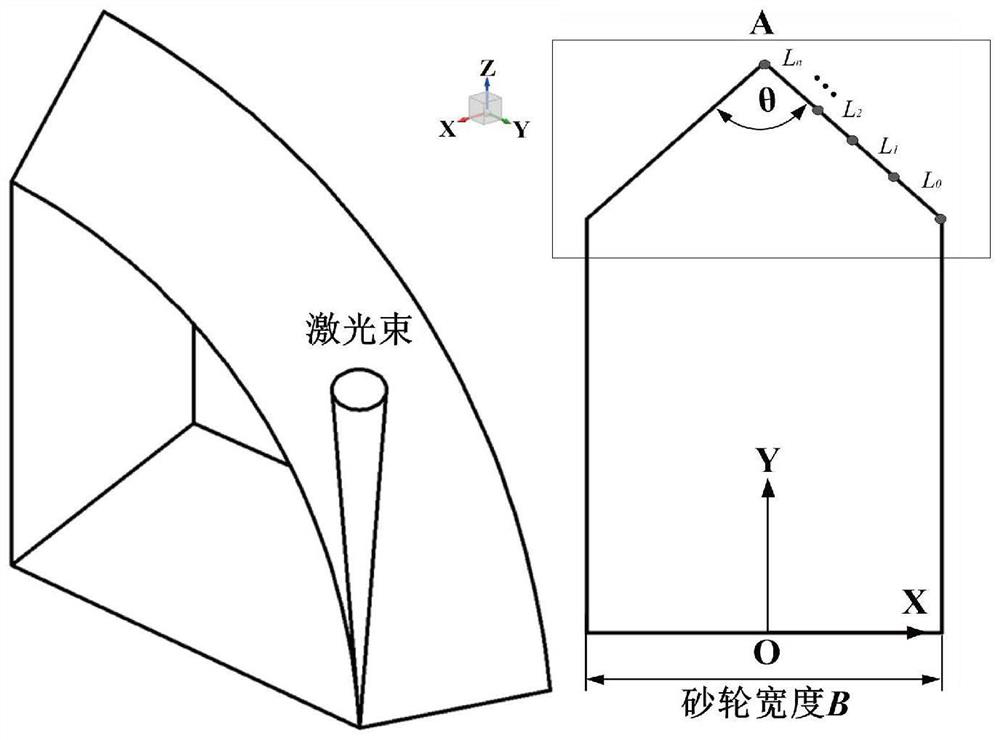

[0089] as attached Figures 1 to 6 As shown, the laser shaping trajectory planning method for forming grinding wheels described in this embodiment specifically includes the following steps:

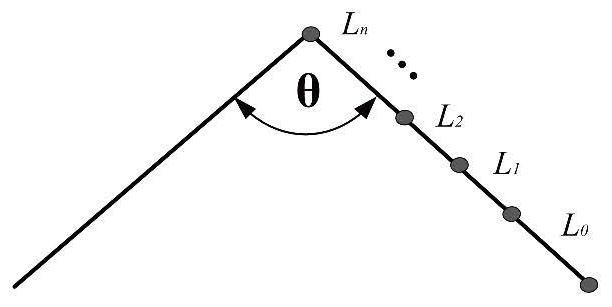

[0090] Step 1, laser shaping trajectory planning of forming grinding wheel, as attached Figure 1-3 shown. Since the shaping trajectory of the V-shaped grinding wheel is symmetrical on the left and right, it can be divided into left and right sides. Taking the right half as an example, the laser shaping trajectory planning is carried out. The total planned length can be expressed as:

[0091] L=L 0 +L 1 +L 2 +...+L n

[0092] Step 2, determine the laser removal energy threshold E of abrasive particles 阈值 ;

[0093]

[0094] In the formula, is the laser energy density at the center of the beam, which can be expressed as: e p is the energy of a single pulse. ω0 is the spot radius of the laser beam at the focal point. w is the width of the ablation pit / groove, when w=0, E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com