Automatic pipe welding machine and dust removal mechanism thereof

An automatic welding and pipe machine technology, applied to welding equipment, welding equipment, tubular objects, etc., can solve the problems of time-consuming, unsatisfactory rust removal effect, etc., and achieve the effect of improving production efficiency and ensuring dust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

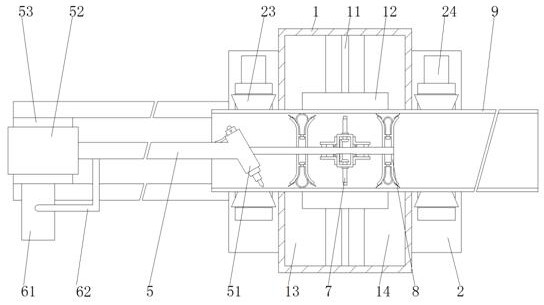

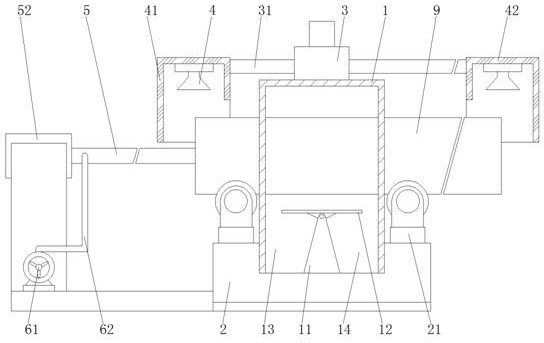

[0036] Specific implementation mode 1: Please refer to Figure 1-6 , the first aspect of the present invention: a dust removal mechanism of an automatic pipe welding machine, comprising:

[0037] The collection box 1 is placed on the base 2, the left and right sides of the collection box 1 are symmetrically provided with openings 15, the inner bottom end of the collection box 1 is fixed with a partition 11, and the top surface of the partition 11 is hingedly installed with a guide plate 12;

[0038] The top seat 3 is arranged on the top surface of the collecting box 1, and a guide rail 31 is inserted into the top seat 3, and the two ends of the guide rail 31 are respectively connected to the left air collecting box 41 and the right air collecting box 42;

[0039] The air extraction head 4, the left air collection box 41 and the right air collection box 42 are evenly installed with the air extraction head 4;

[0040] The gas delivery pipe 6, the right end of the gas delivery p...

specific Embodiment approach 2

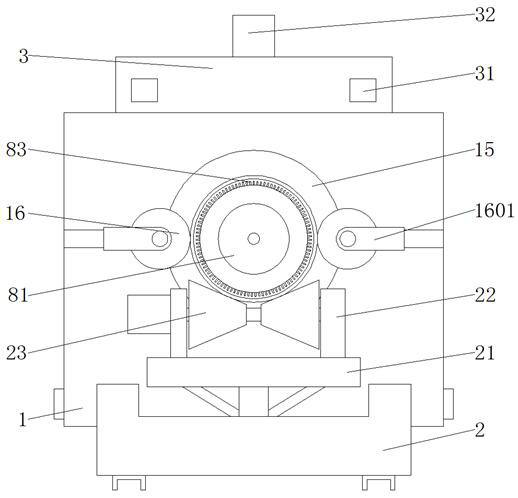

[0043] Embodiment 2: This embodiment is a further limitation of Embodiment 1, such as figure 1 and image 3As shown, limit wheels 16 are installed on the left and right sides of the collection box 1. There are four limit wheels 16 in total. A connecting plate 1601 is installed on the outer side of the limit wheel 16, and the other end of the connecting plate 1601 is fixedly connected. Abutting block 1602, the abutting block 1602 enters the collection box 1 through the chute 1603, the chute 1603 is symmetrically distributed about the opening 15, the collection box 1 is used to collect solid large particles of debris, the solder tank 13 and the waste slag tank 14 are close to each other. The openings 15 on the left and right sides of the collection box 1 realize separate collection, which is convenient for subsequent recycling and reuse.

specific Embodiment approach 3

[0044] Embodiment 3: This embodiment is a further limitation of Embodiment 2, such as Figure 4 As shown, an isosceles triangle-shaped partition 11 is fixed in the middle of the bottom surface of the collecting box 1. The partition 11 separates the bottom space of the collecting box 1 to form a solder tank 13 and a waste slag tank 14. The solder tank 13 is close to the welding gun 51, and the solder tank 13 and A rotating shaft 18 is installed in the waste slag tank 14. The rotating shaft 18 is sleeved with a long rod 17 and a short rod 19. The long rod 17 and the short rod 19 are in contact with the abutment block 1602 and the guide plate 12 respectively. The long rod 17 and the short rod 19 rotates around the rotating shaft 18, when the abutting block 1602 pushes the long rod 17, the short rod 19 lifts the guide plate 12 upward, and the short rod 19 is fixed with a counterweight block, when the abutting block 1602 is reset, the short rod 19 is in the The action of gravity ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com