Universal concentrated solution complexing agent for hydraulic support

A technology of hydraulic support and concentrated liquid, which is applied in the direction of additives, lubricating compositions, petroleum industry, etc., can solve the problems of sudden increase in product cost and increased dosage, and achieve the effects of single model, shortened blending time, and convenient storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] In the embodiment of the present invention, a general-purpose hydraulic support concentrated liquid compound is composed of the following substances by mass fraction:

[0043] Rust inhibitor 8-15%;

[0044] Triazole 0.05-0.1%;

[0045] Synthetic non-ionic lubricating and anti-rust multi-functional additive for extra-high hard water resistance 5-8%;

[0046] Triethanolamine 2-4%;

[0047] Ricinoleic acid 1-3%;

[0048] Swire Oil 2-4%;

[0049] Defoamer 0.05-0.15%;

[0050] Water 15-82%.

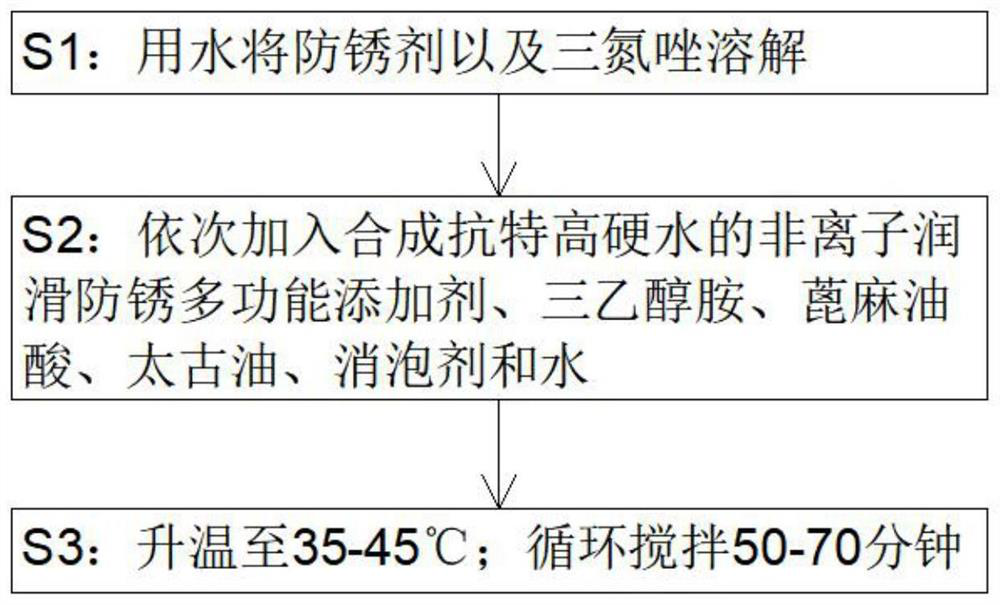

[0051] Preferably, its preparation method comprises the following steps:

[0052] S1: Dissolve the rust inhibitor and triazole with water;

[0053] S2: adding the non-ionic lubricating and anti-rust multifunctional additive for synthesizing extra-high hard water, triethanolamine, ricinoleic acid, swire oil, defoamer and water in sequence;

[0054] S3: raise the temperature to 35-45°C; circulate and stir for 50-70 minutes.

[0055] Preferably, the time for circulating stirring i...

Embodiment 2

[0058] In the embodiment of the present invention, a general-purpose hydraulic support concentrated liquid compound is composed of the following substances by mass fraction:

[0059] Rust inhibitor 8-15%;

[0060] Triazole 0.05-0.1%;

[0061] Synthetic non-ionic lubricating and anti-rust multi-functional additive for extra-high hard water resistance 5-8%;

[0062] Triethanolamine 2-4%;

[0063] Ricinoleic acid 1-3%;

[0064] Swire Oil 2-4%;

[0065] Defoamer 0.05-0.15%;

[0066] Water 15-82%.

[0067] Preferably, it is composed of the following substances by mass fraction:

[0068] Rust inhibitor 8-15%;

[0069] Triazole 0.05-0.1%;

[0070] Synthetic non-ionic lubricating and anti-rust multi-functional additive for extra-high hard water resistance 5-8%;

[0071] Triethanolamine 2-4%;

[0072] Ricinoleic acid 1-3%;

[0073] Swire Oil 2-4%;

[0074] Defoamer 0.05-0.15%;

[0075] Water 65.75-81.9%.

[0076] Preferably, its preparation method comprises the following ...

Embodiment 3

[0083] In the embodiment of the present invention, a general-purpose hydraulic support concentrated liquid compound is composed of the following substances by mass fraction:

[0084] Rust inhibitor 8-15%;

[0085] Triazole 0.05-0.1%;

[0086] Synthetic non-ionic lubricating and anti-rust multi-functional additive for extra-high hard water resistance 5-8%;

[0087] Triethanolamine 2-4%;

[0088] Ricinoleic acid 1-3%;

[0089] Swire Oil 2-4%;

[0090] Defoamer 0.05-0.15%;

[0091] Water 15-82%.

[0092] Preferably, it is composed of the following substances by mass fraction:

[0093] Rust inhibitor 8-15%;

[0094] Triazole 0.05-0.1%;

[0095] Synthetic non-ionic lubricating and anti-rust multi-functional additive for extra-high hard water resistance 5-8%;

[0096] Triethanolamine 2-4%;

[0097] Ricinoleic acid 1-3%;

[0098] Swire Oil 2-4%;

[0099] Defoamer 0.05-0.15%;

[0100] Water 15.75-31.9%.

[0101] Preferably, its preparation method comprises the following ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com