Multi-cavity laundry condensate bead

A technology of laundry beads and chambers, applied in the field of daily chemical detergents, can solve the problems of difficulty in forming a dissolving and dispersing system, low moisture content, etc., and achieve the effects of good softening effect, reducing stiffness and improving product safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation method of the multi-chamber laundry beads of the present invention is as follows:

[0031] 1. Preparation method of liquid detergent in multi-chamber laundry beads:

[0032] (1) drop the solvent into the reactor, stir;

[0033] (2) Alkylbenzenesulfonic acid monoethanolamine salt and fatty acid monoethanolamine salt adopt alkylbenzenesulfonic acid, fatty acid and monoethanolamine to drop into reactor and carry out neutralization reaction preparation: drop into monoethanolamine in reactor, drop into the fatty acid of molten state The reaction kettle, put the alkylbenzene sulfonic acid into the reaction kettle, stir evenly, and complete the neutralization reaction;

[0034] (3) adding modified lignosulfonate in the reactor, stirring uniformly;

[0035] (4) dropping the nonionic surfactant in molten state into the reactor;

[0036] (5) Add flavors, pigments, etc.

[0037] 2. Preparation method of softening detergent in multi-chamber laundry beads:

[00...

Embodiment

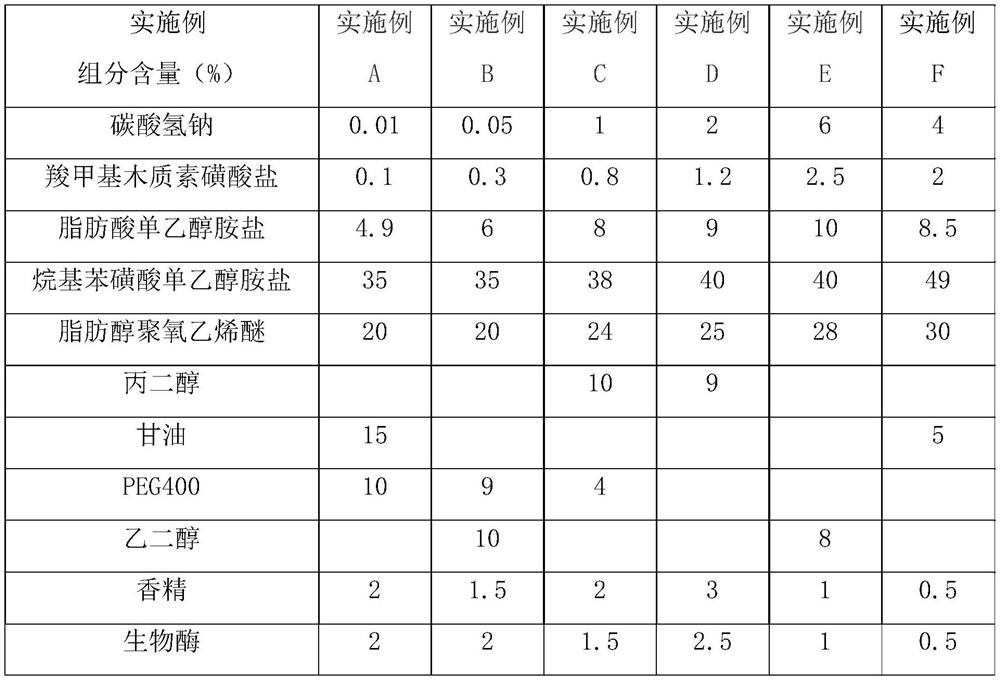

[0047] Table 1 lists examples of concentrated fabric detergents and Table 2 lists examples of concentrated softening detergents. The examples in Table 1 and Table 2 prepared multi-chamber laundry beads according to the mass percentages listed in Table 3.

[0048] Table 1: Examples of Concentrated Fabric Detergents

[0049]

[0050]

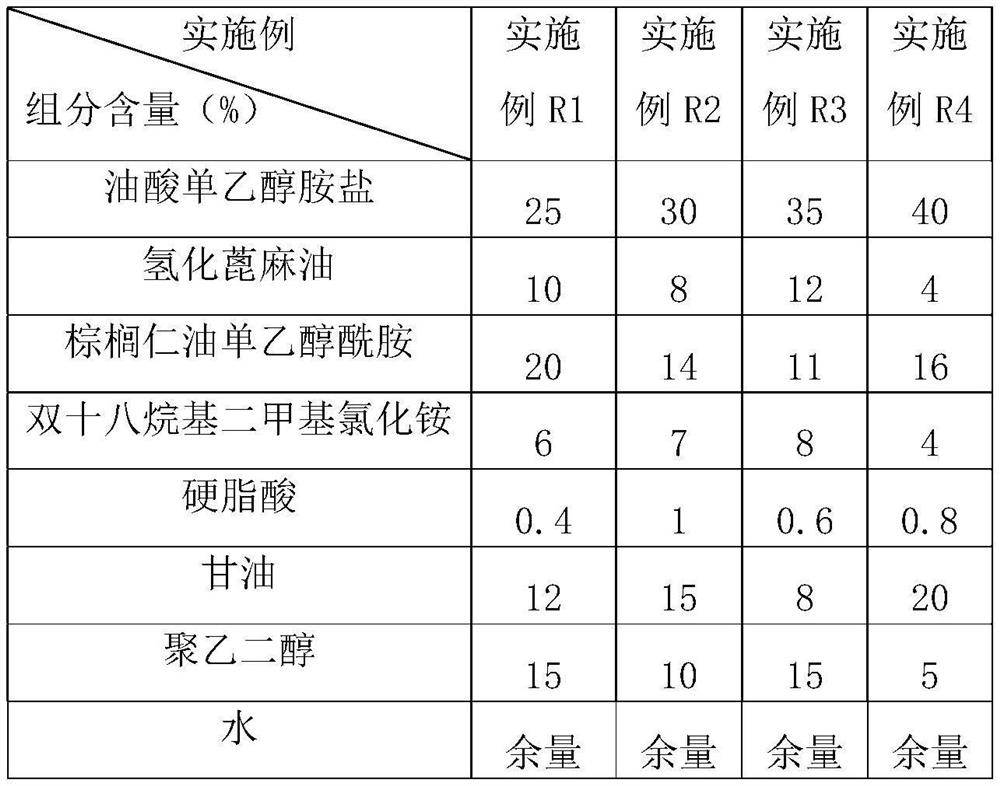

[0051] Table 2: Examples of Concentrated Fabric Softening Detergents

[0052]

[0053] Table 3: Mass ratio of fabric detergent to softener

[0054] Example 1 Example 2 Example 3 Example 4 Example 5 Example 6 Example A 10g Example B 20g Example C 20g Example D 15g Example E 8g Example F 12g Example R1 4g Example R2 6g 6g Example R3 8g 3g Example R4 5g

[0055] 4. Determination of Detergent Ability of Examples

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com