Energy-saving type steam-water universal boiler

An energy-saving, steam-water technology, which is applied in steam boilers, steam generation, lighting and heating equipment, etc., can solve problems affecting the heat recovery rate of flue gas, unreasonable structure, arrangement, and large equipment occupation area, so as to save installation Consumables, improved versatility and replacement, and space-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

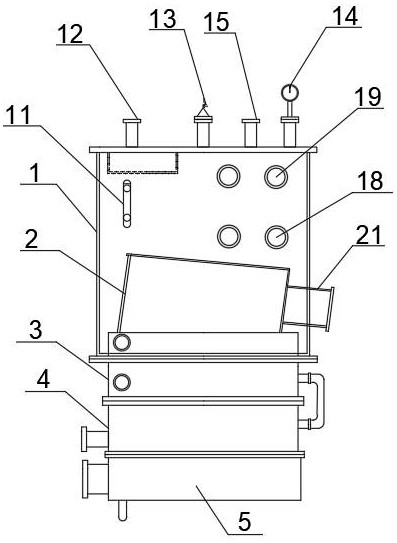

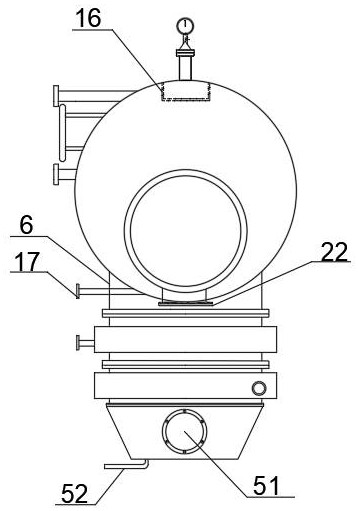

[0040] To make the purposes, technical solutions, and advantages of the embodiments of the present invention clearer, the following will combine the appendices of the embodiments of the present invention. Figure 1-4 , to clearly and completely describe the technical solutions of the embodiments of the present invention. Obviously, the described embodiments are some, but not all, embodiments of the present invention. Based on the described embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art fall within the protection scope of the present invention.

[0041] like Figure 1-2 shown:

[0042] An energy-saving general-purpose steam-water boiler, comprising a drum 1, an economizer 3 disposed below the drum 1, a condenser 4 disposed below the economizer 3, and a smoke box 5 disposed below the condenser 4;

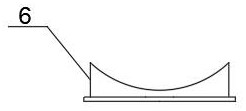

[0043] The drum 1 is provided with an eccentric furnace 2, the axis of the eccentric furnace 2 deviates downward relativ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com