Full-automatic multifunctional gas detecting and cleaning all-in-one machine

A gas detection and multi-functional technology, applied in fluid tightness testing, liquid tightness measurement using liquid/vacuum degree, measuring device, etc., can solve the problem of high cost of use, lack of fresh air bag cleaning sample analysis, and inaccuracy To improve accuracy, avoid low detection data, and ensure cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

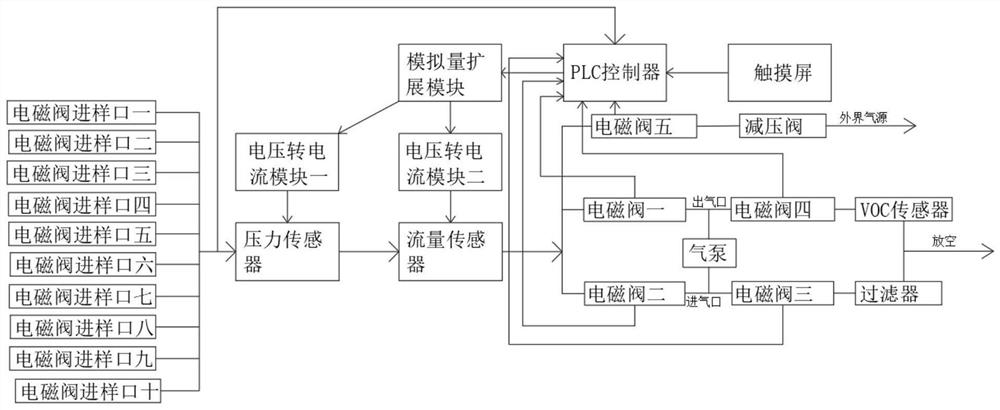

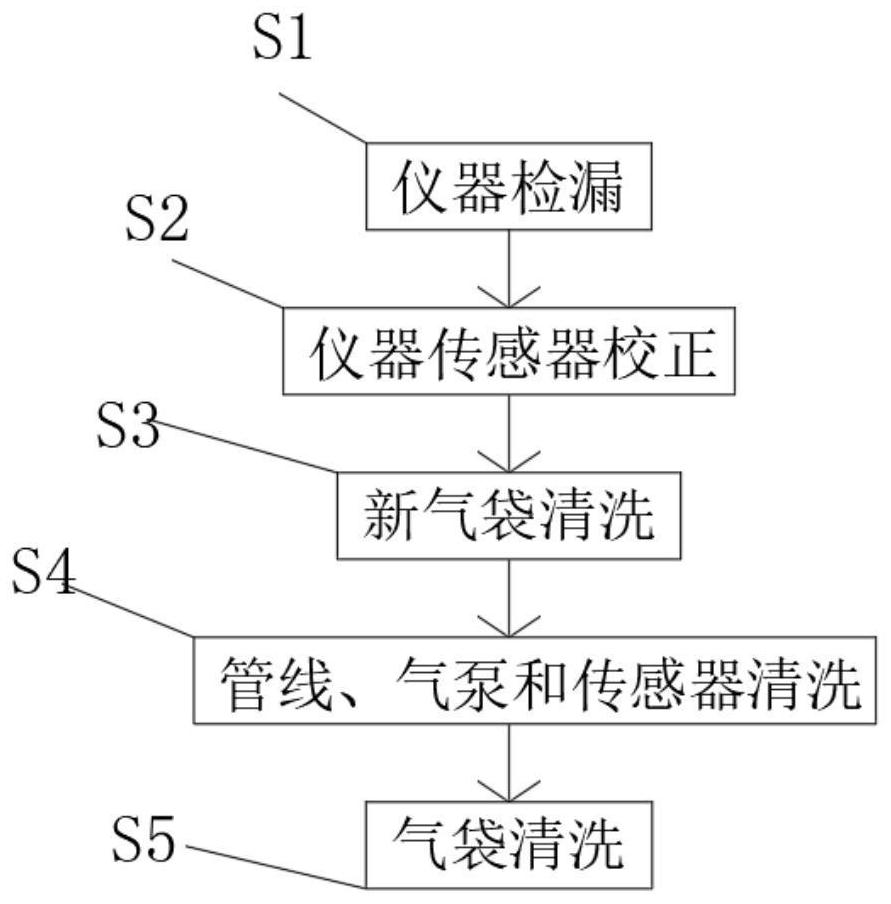

[0031] like Figure 1-2 As shown, the embodiment of the present invention provides a fully automatic multi-function gas detection and cleaning integrated machine, including a PLC controller, a pressure sensor, a flow sensor, a solenoid valve 1, a solenoid valve 2, a solenoid valve 3, a solenoid valve 4, a solenoid valve 5, a filter controller, pressure reducing valve, voltage-to-current module 1, voltage-to-current module 2, analog expansion module and air pump, PLC controller is connected with solenoid valve inlet 1, solenoid valve inlet 2, solenoid valve through electrical signal lines Injection port 3, solenoid valve injection port 4, solenoid valve injection port 5, solenoid valve injection port 6, solenoid valve injection port 7, solenoid valve injection port 8, solenoid valve injection port 9 and solenoid valve inlet The sample ports are connected to each other, and the PLC controller is used as the controller. Combined with the program, the solenoid valve switch of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com