Method and system for reducing carbon content of fly ash of boiler

A fly ash carbon content and boiler technology, which is applied in the field of boilers in thermal power plants, can solve the problems of excessive carbon content in fly ash, inaccurate measurement results, neglect of adjustment and control of boiler combustion efficiency, etc., to reduce safety and ensure The effect of combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

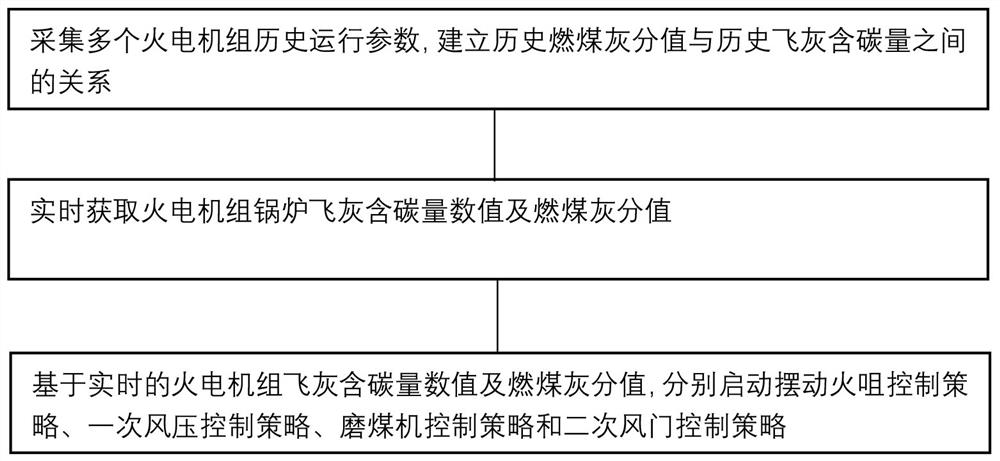

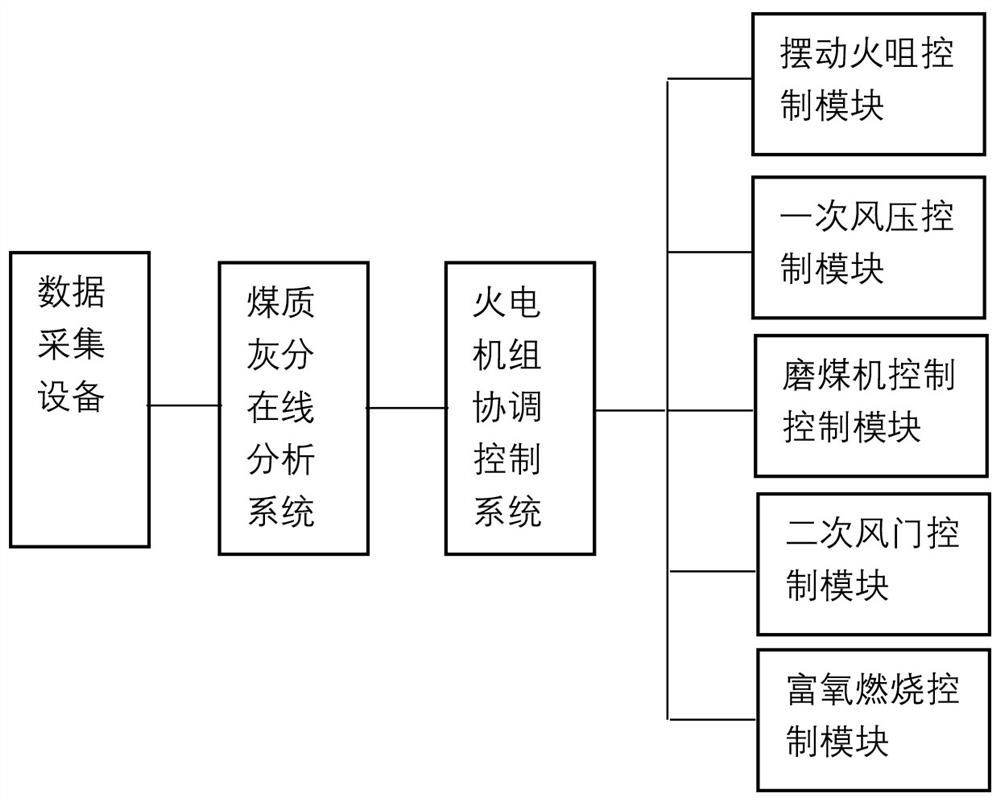

[0049] see Figure 1-6 , a method for reducing the carbon content of boiler fly ash, comprising the following steps:

[0050] Collect historical operating parameters of multiple thermal power units to establish the relationship between historical coal ash content and historical fly ash carbon content;

[0051] Real-time acquisition of carbon content and coal-fired ash content in the boiler fly ash of thermal power units;

[0052] Based on the real-time carbon content value in the fly ash of the thermal power unit and the coal ash content value, the swing burner control strategy, the primary air pressure control strategy, the coal mill control strategy and the secondary air valve control strategy are activated respectively.

[0053] Further, the operating parameters include thermal power unit load, boiler efficiency, total coal amount and carbon content in fly ash.

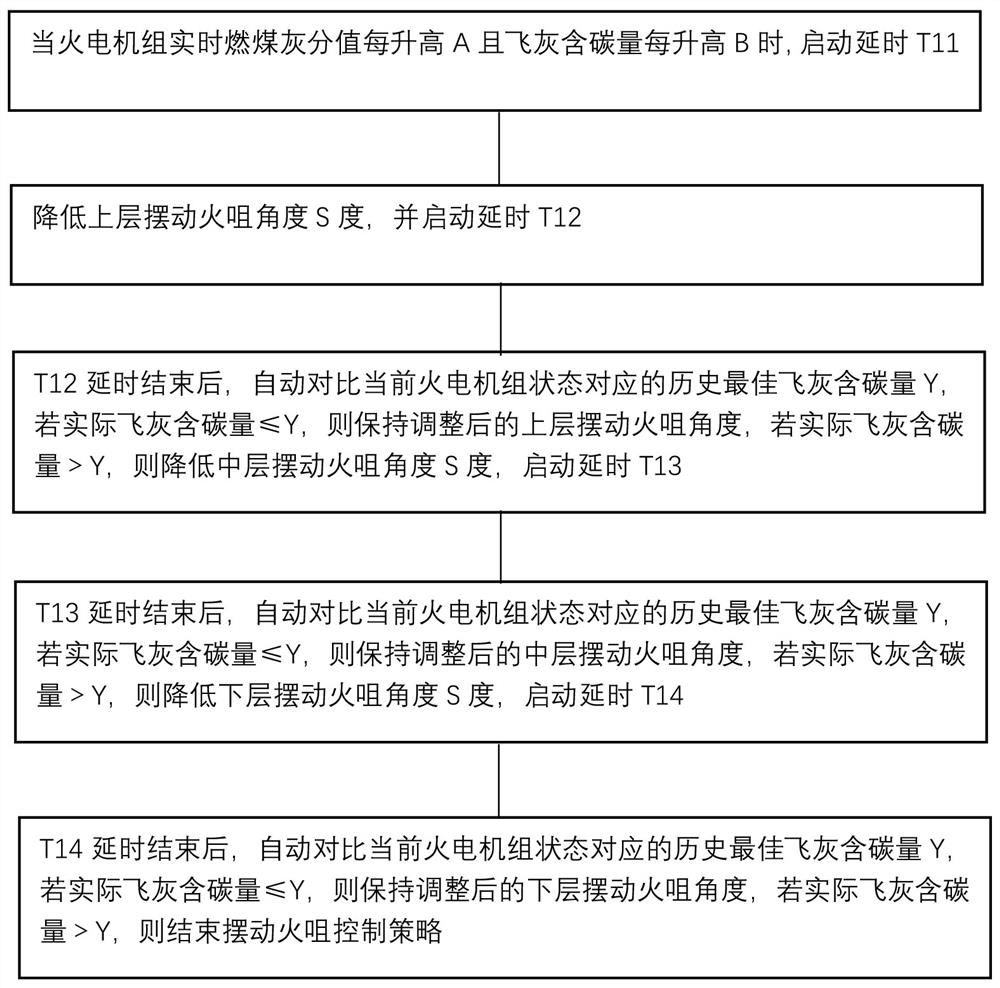

[0054] Further, the swing burner control strategy includes the following steps:

[0055] When the real-time c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com