Method for analyzing starting performance of cage type motor

A technology of starting performance and analysis method, applied in computer-aided design, design optimization/simulation, calculation, etc., can solve problems such as calculation error, no bidirectional coupling of electromagnetic and temperature, ignoring the bidirectional influence of electromagnetic loss and temperature rise, etc., to avoid The effect of poor reliability, avoiding excessive calculation, and short calculation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0058] As a preferred embodiment of the present invention, this embodiment discloses a method for analyzing the starting performance of a squirrel motor, which includes the following steps:

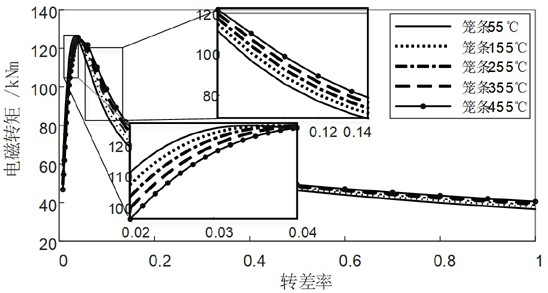

[0059] S1. Perform finite element modeling and coupling circuit modeling of the motor body, set boundary conditions, perform finite element solution and post-processing, and obtain a series of data required for subsequent calculations, including different stator voltages, different rotational speeds, and different rotors. The electromagnetic torque of the motor and the loss of each component under the temperature, and the obtained data is exported to the database;

[0060] S2. Start the calculation from the speed of 0 and the starting temperature of the cage bar as the input, and perform two-dimensional interpolation of the speed and the temperature of the cage bar from the database, and the output result is the electromagnetic torque and the instantaneous loss of each component;

[0061]...

Embodiment 2

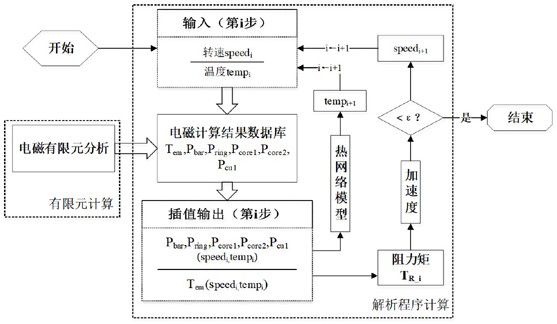

[0069] As another preferred embodiment of the present invention, refer to the accompanying figure 1 , this embodiment provides a method for analyzing the starting performance of a squirrel motor, including the following steps:

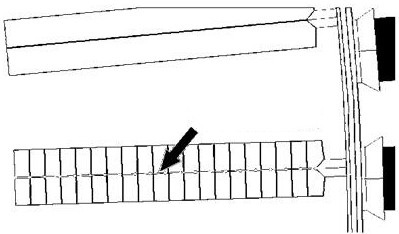

[0070] S1. Carry out the finite element modeling and coupling circuit modeling of the motor body, reserve the parameter interface of temperature in the modeling process, divide the cage bars into blocks along the groove depth direction, set the boundary conditions, carry out the finite element solution and then process to obtain a series of data required for subsequent calculations, the data includes different stator voltages, different rotational speeds, and different rotor temperatures. The electromagnetic torque Tem of the motor, the stator current Is, the cage bar loss Pbar, the end ring loss Pring, For the stator iron loss Pcore1 and the rotor iron loss Pcore2, the obtained data is exported to a database, and the data in the database is presented ...

Embodiment 3

[0083] As another preferred embodiment of the present invention, refer to the accompanying figure 2 , this embodiment provides a method for analyzing the starting performance of a squirrel motor, including the following steps:

[0084] S1. Carry out the finite element modeling and coupling circuit modeling of the motor body, reserve the parameter interface of temperature in the modeling process, divide the cage bars into blocks along the groove depth direction, set the boundary conditions, carry out the finite element solution and then process to obtain a series of data required for subsequent calculations, the data includes the electromagnetic torque of the motor and the loss of each component under different stator voltages, different rotational speeds, and different rotor temperatures, and export the obtained data to the database;

[0085] S2. Start the calculation from the speed of 0 and the starting temperature of the cage bar as the input, and perform two-dimensional in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com