Mechanical transmission decoupling method for multi-axis robot

A multi-axis robot and mechanical transmission technology, applied in the direction of manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of increasing robot calculation and control accuracy errors, increasing the complexity of control and control algorithms, and different speed adjustment ranges. The difficulty of control, low requirements, and the effect of reducing accuracy errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

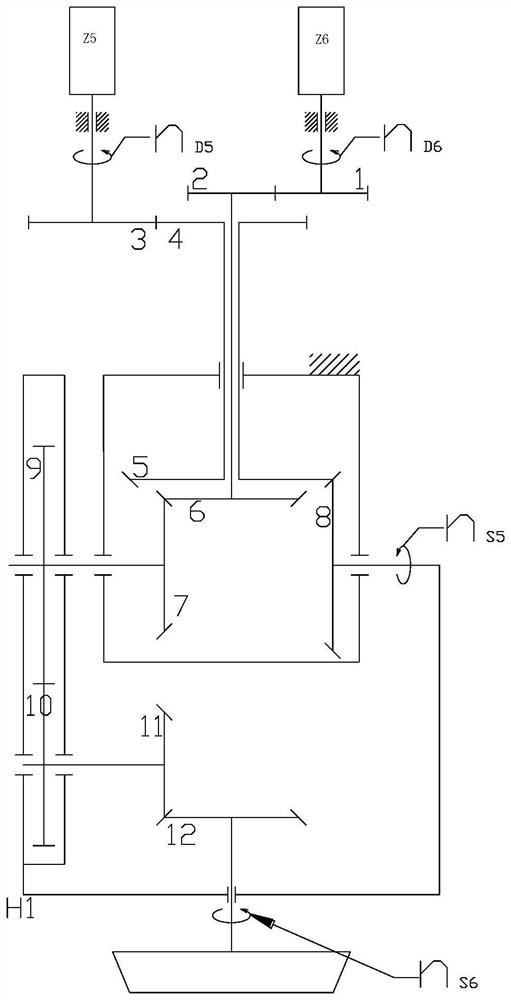

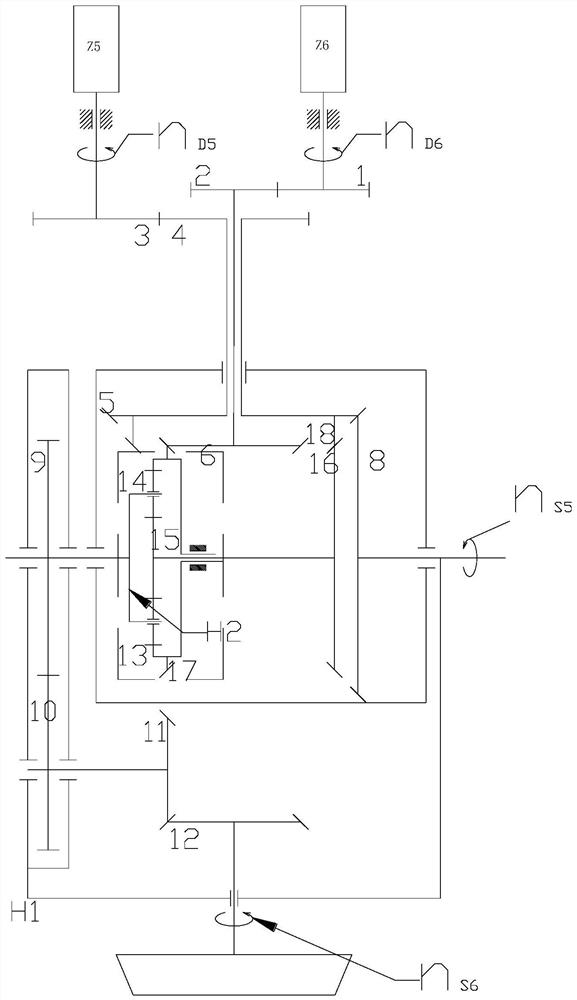

[0072] The present invention will be described in detail below with reference to the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. In addition, according to the description in this document, those skilled in the art can make corresponding combinations of features in the embodiments in this document and in different embodiments.

[0073] Examples of the present invention are as follows, refer to figure 1 , a method for decoupling the mechanical transmission of a multi-axis robot, comprising the following steps:

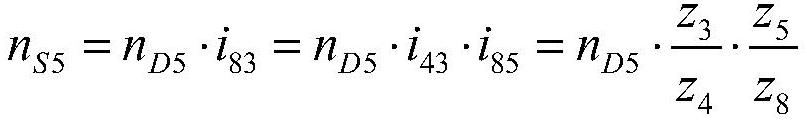

[0074] (1) The original mechanical transmission condition is analyzed and refined, and the original transmission function relationship is obtained, in which the rotational speed of the working unit of one axis is the dependent variable, and the factor affecting the rotational speed of the working unit of the axis is the independent variable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com