Method for improving escherichia coli protein expression quantity through staged dissolved oxygen control

A technology of protein expression and Escherichia coli, which is applied in the field of fermentation engineering, can solve the problems of decreased cell viability, protein degradation, cell aging, etc., to increase expression, slow cell aging and autolysis, and maintain cell vitality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

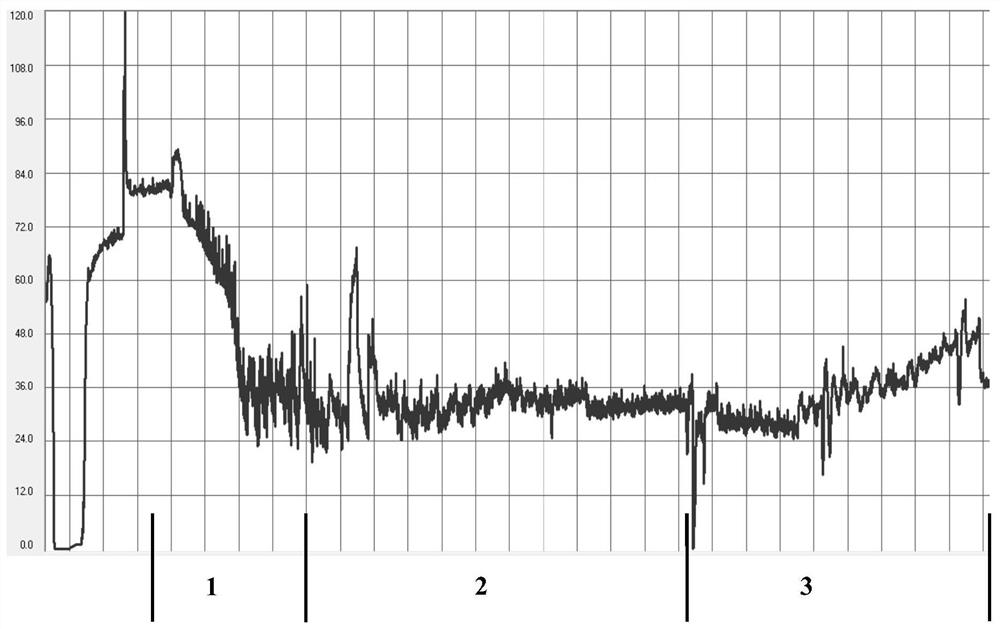

Embodiment 1

[0043] Example 1 The 30L fermentation of genetically engineered bacteria A only includes the first-stage induction;

[0044] 1) First-class seed culture: inoculate the strains into the first-class seed medium, and shake at 30°C and 250rpm for 12-16 hours to obtain first-class seed liquid; the first-class seed medium is LB medium, sodium chloride 10g / L, yeast extract powder 5g / L, peptone 10g / L, sterilized at 121°C for 20min.

[0045] 2) Secondary seed culture: inoculate primary seeds into secondary seed medium, and shake and cultivate at 37°C and 250 rpm for 3 to 6 hours to obtain secondary seed liquid; secondary seed medium is LB medium, 10 g of sodium chloride / L, yeast extract powder 5g / L, peptone 10g / L, sterilized at 121°C for 20min.

[0046] 3) 30L fermentation

[0047] a. Initial culture stage: first prepare 12L fermentation medium, sterilize at 121°C for 20min, cool down to 30°C; adjust pH to 6.7, inoculate 1.2L secondary seeds into the fermenter, the dissolved oxygen...

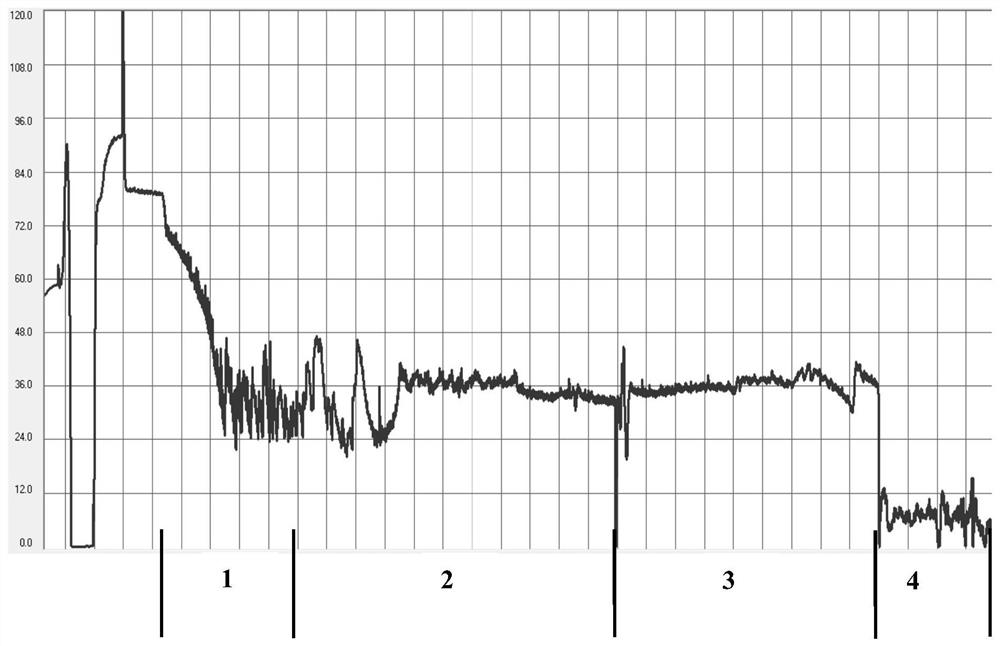

Embodiment 2

[0057] Example 2 30L fermentation of genetically engineered bacteria A, including first-stage induction and second-stage induction;

[0058] 1) First-class seed culture: inoculate the strains into the first-class seed medium, and shake at 30°C and 250rpm for 12-16 hours to obtain first-class seed liquid; the first-class seed medium is LB medium, sodium chloride 10g / L, yeast extract powder 5g / L, peptone 10g / L, sterilized at 121°C for 20min.

[0059] 2) Secondary seed culture: inoculate primary seeds into secondary seed medium, and shake and cultivate at 37°C and 250 rpm for 3 to 6 hours to obtain secondary seed liquid; secondary seed medium is LB medium, 10 g of sodium chloride / L, yeast extract powder 5g / L, peptone 10g / L, sterilized at 121°C for 20min.

[0060] 3) 30L fermentation

[0061] a. Initial culture stage: first prepare 12L fermentation medium, sterilize at 121°C for 20min, cool down to 30°C; adjust pH to 6.7, inoculate 1.2L secondary seeds into the fermenter, the ...

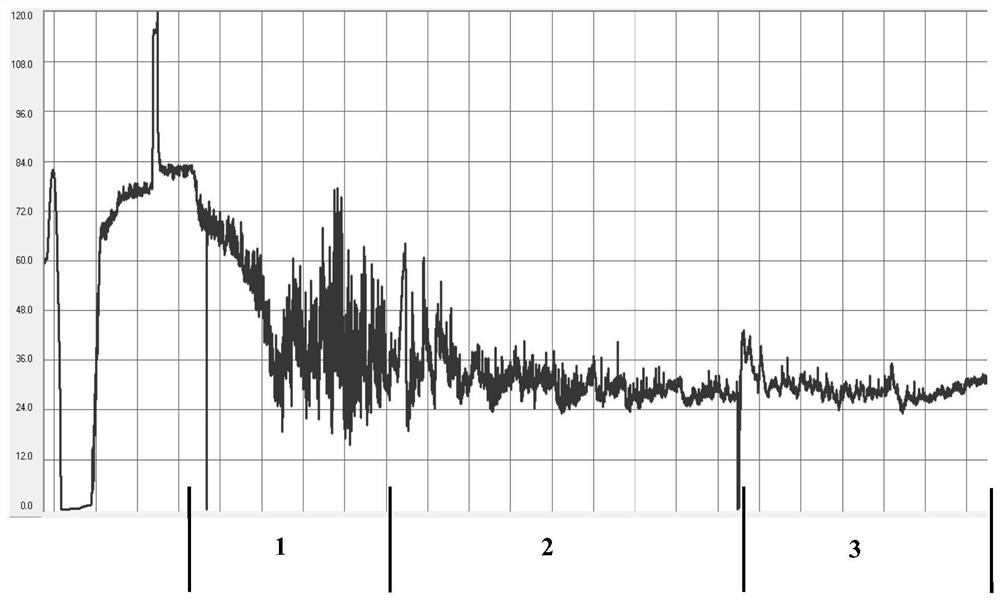

Embodiment 3

[0072] Example 3 The 30L fermentation of genetically engineered bacteria B only includes the first-stage induction;

[0073] 1) First-class seed culture: inoculate the strains into the first-class seed medium, and shake at 30°C and 250rpm for 12-16 hours to obtain first-class seed liquid; the first-class seed medium is LB medium, sodium chloride 10g / L, yeast extract powder 5g / L, peptone 10g / L, sterilized at 121°C for 20min.

[0074] 2) Secondary seed culture: inoculate primary seeds into secondary seed medium, and shake and cultivate at 37°C and 250 rpm for 3 to 6 hours to obtain secondary seed liquid; secondary seed medium is LB medium, 10 g of sodium chloride / L, yeast extract powder 5g / L, peptone 10g / L, sterilized at 121°C for 20min.

[0075] 3) 30L fermentation

[0076] a. Initial culture stage: first prepare 12L fermentation medium, sterilize at 121°C for 20min, cool down to 30°C; adjust pH to 6.7, inoculate 1.2L secondary seeds into the fermenter, the dissolved oxygen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com