Uniform energy-saving type textile fabric drying equipment

A technology for textile fabrics and drying equipment, which is applied to the processing, drying, and dryers of textile materials. It can solve problems such as uneven drying of fabrics and waste of heat energy, so as to avoid excessive loss, save energy, and reduce stress. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

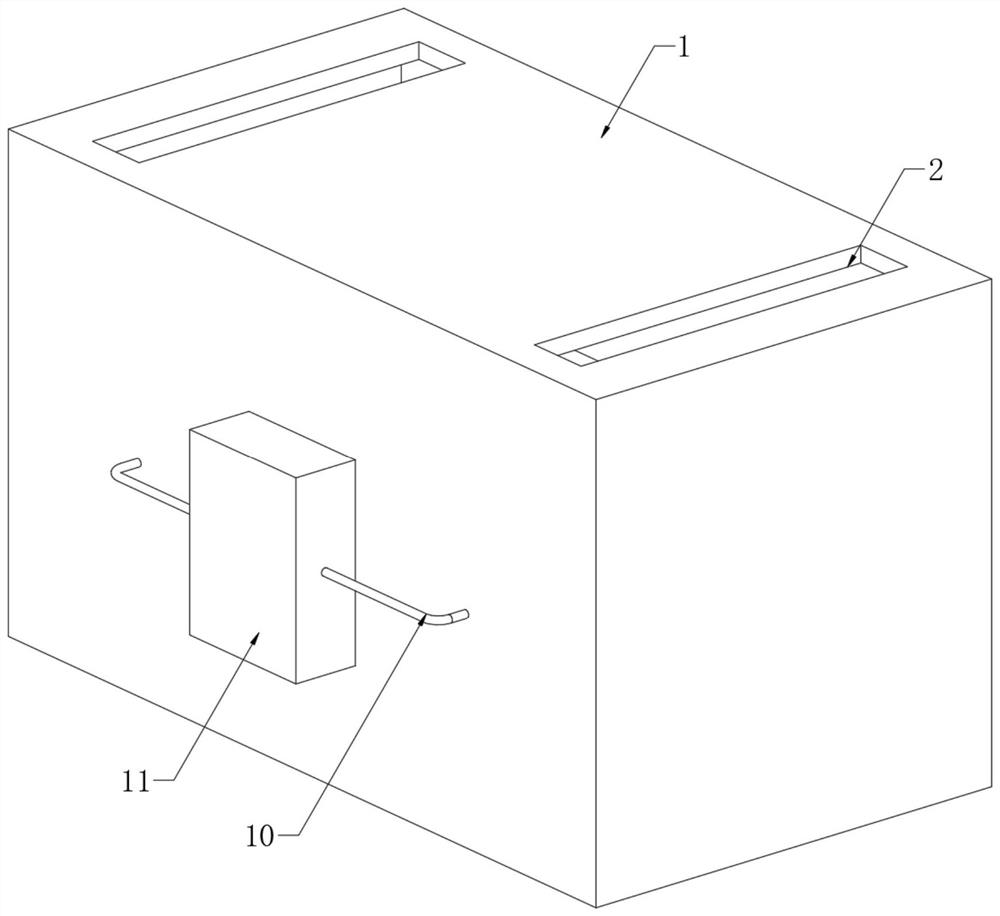

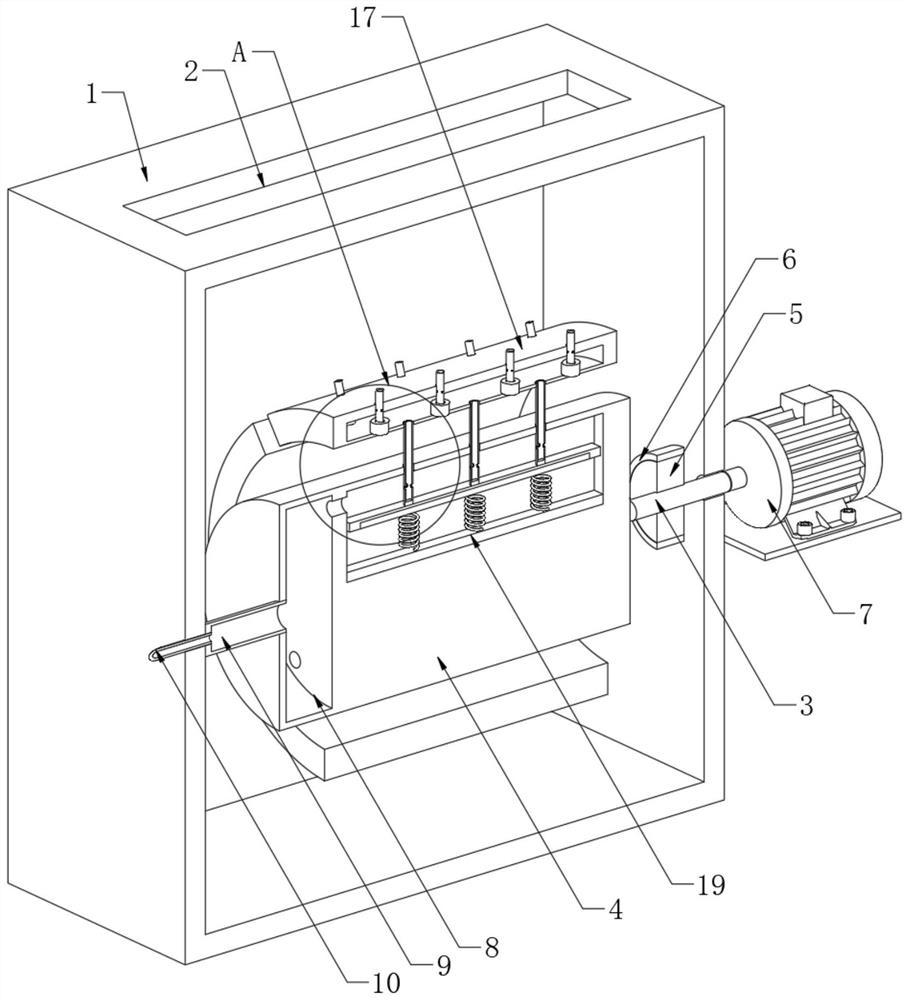

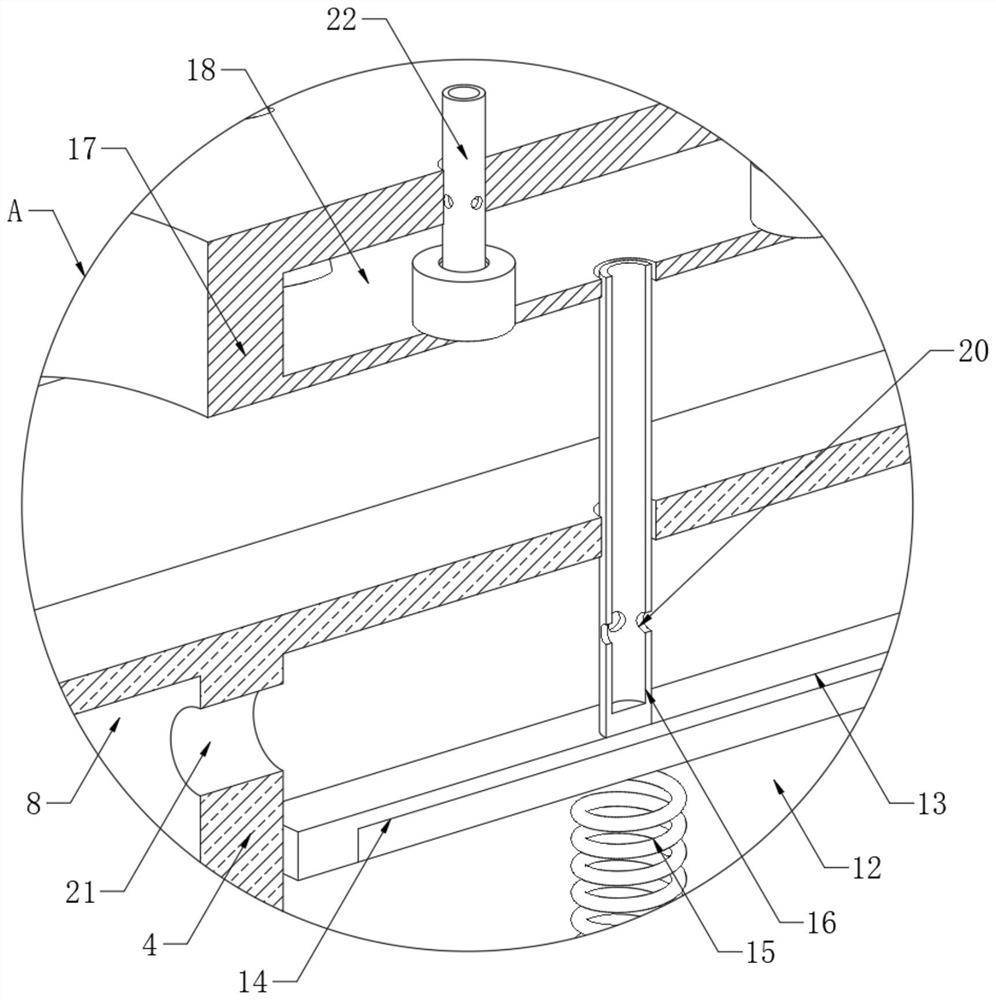

[0021] refer to figure 2 , image 3 , Image 6 and Figure 7 , a uniform and energy-saving textile cloth drying equipment, including a box body 1, the upper end of the box body 1 is symmetrically provided with two passages 2 for entering and leaving the cloth, and the box body 1 is installed symmetrically and horizontally through the rotating shaft 3 A plurality of chutes 12 are evenly opened in the rotating roller 4 along the circumferential direction. Each chute 12 is connected with an arc-shaped plate 17 through a reciprocating mechanism, and the arc-shaped plate 17 is provided with a circulation channel in a sub-arc shape. Slot 18, a plurality of spray heads 22 are evenly and fixedly connected to the flow groove 18, each spray head 22 includes a fixed cylinder 2201 fixedly connected to the groove wall of the flow groove 18, and the inner bottom wall of each fixed cylinder 2201 passes through the limit spring 2202 A movable plate 2203 is elastically connected, each mova...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com