On-line full-automatic sampling, sample preparation and moisture determination system and method for iron ore

A determination system and technology for iron ore, applied in the field of sampling, preparation, detection and analysis of iron ore raw materials, can solve the problems of large fluctuation of analysis results, deviation of measurement and sample preparation, low degree of automation, etc. High degree of automation to ensure the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to facilitate the understanding of the present invention by those skilled in the art, the specific embodiments of the present invention are described below with reference to the accompanying drawings.

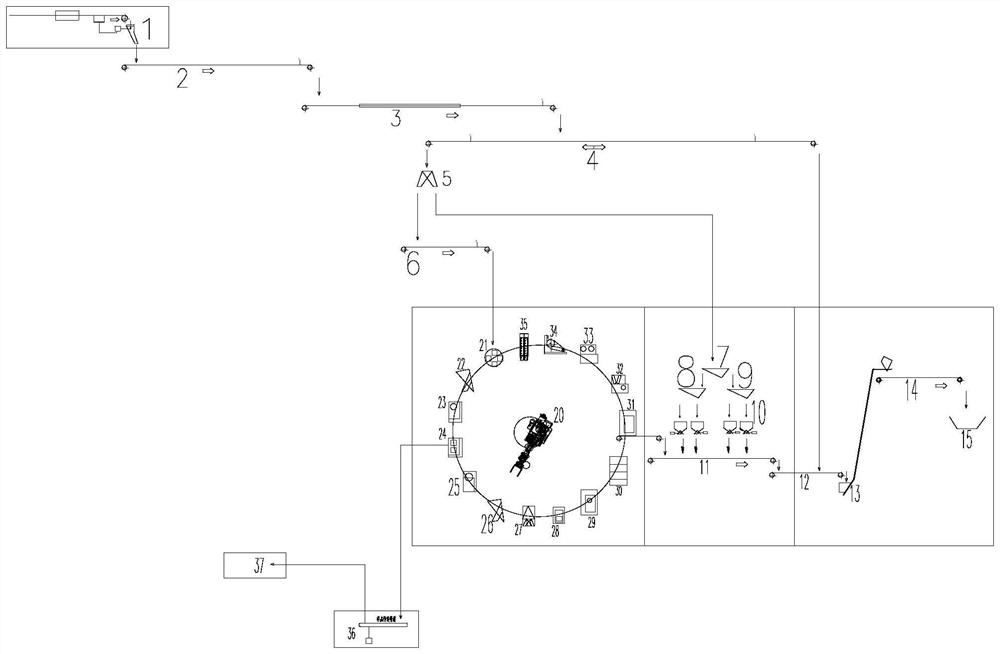

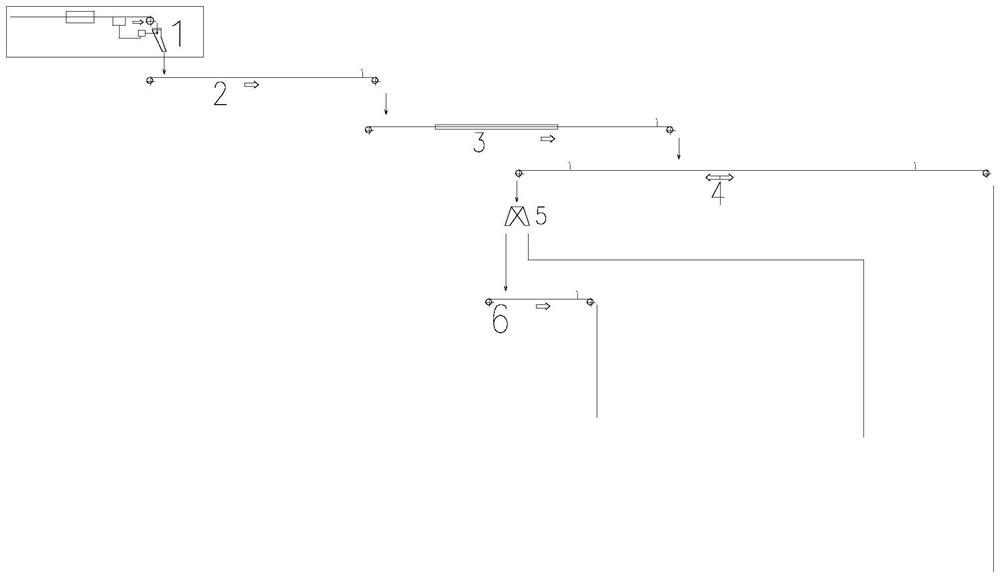

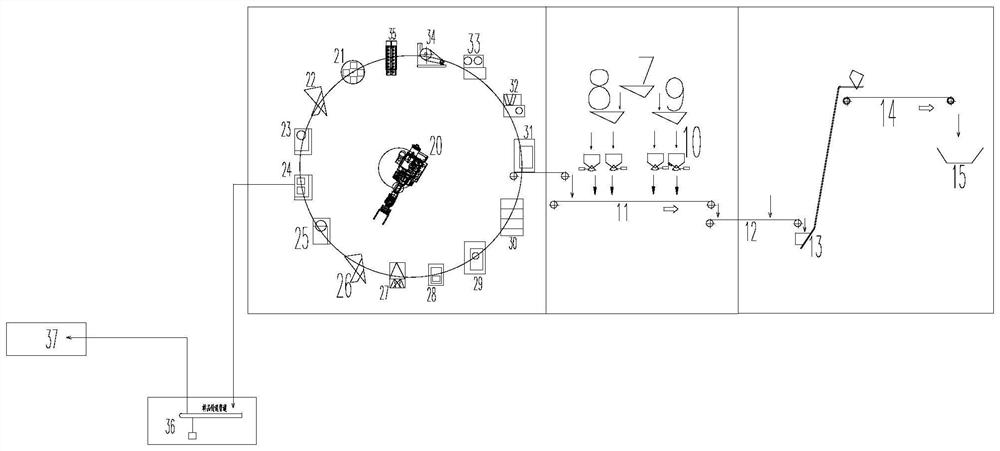

[0042] like Figure 1-Figure 3 As shown, the system includes a sampling and transmission unit, a particle size determination unit, a robotic sample preparation and analysis unit, and a sample disposal unit. The system also includes a control center that uniformly controls the operation of all equipment, with a computer and PLC as the core for control.

[0043] The sampling transmission unit includes the primary sampling machine 1, the No. 1 incoming sample belt conveyor 2, the No. 2 incoming sample measuring belt conveyor 3, the No. 3 incoming sample belt conveyor 4, the iron ore secondary sampling machine 5, and the No. 1 iron ore system transfer unit. Connect the belt conveyor 6. In this implementation case, a set of sampling, preparation, analysis and determ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com