Automatic production process of cup-shaped mask

A production process and mask technology, which is applied in the field of automatic production technology of cup-shaped masks, can solve the problems of difficulty in realizing automation and low automation efficiency, and achieve the effects of optimizing arrangement and combination, improving production efficiency, and optimizing process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

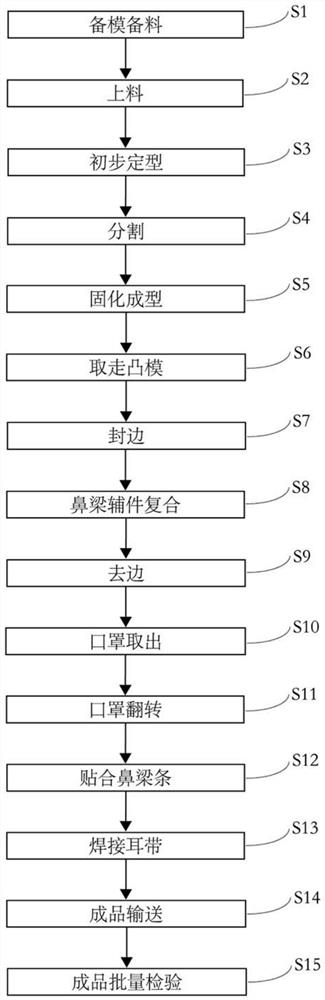

[0046] The invention provides an automatic production process method for a cup-shaped mask, comprising the following steps:

[0047] Step S1, mold preparation and material preparation: prepare the molds required for the production process, the molds are divided into concave molds and punches, and the shape of the mold clamping part is consistent with the shape of the cup-shaped mask; prepare production materials, the middle filter layer of the mask, and the inner layer of the mask. material and the outer layer of the mask; among them, the filter layer in the middle of the mask is 50g / m 2 of melt-blown polypropylene electret, the outer layer of the mask is 150g / m 2 Needle-punched cotton, the inner layer of the mask is 150g / m 2 Needle-punched cotton;

[0048] Step S2, feeding: the middle filter layer material of the mouth mask is sandwiched between the outer layer material of the mouth mask and the inner layer material of the mouth mask by the automatic material rack mechanism...

Embodiment 2

[0063] The invention provides an automatic production process method for a cup-shaped mask, comprising the following steps:

[0064] Step S1, mold preparation and material preparation: prepare the molds required for the production process, the molds are divided into concave molds and punches, and the shape of the mold clamping part is consistent with the shape of the cup-shaped mask; prepare production materials, the middle filter layer of the mask, and the inner layer of the mask. material and the outer layer of the mask; the middle filter layer of the mask is two layers of 25g / m2 2 Melt-blown polypropylene electret composite, the inner layer of the mask is 120g / m 2 Needle-punched cotton, the outer layer of the mask is 120g / m 2 Needle-punched cotton;

[0065] Step S2, feeding: the middle filter layer material of the mouth mask is sandwiched between the outer layer material of the mouth mask and the inner layer material of the mouth mask by the automatic material rack mechan...

Embodiment 3

[0080] The invention provides an automatic production process method for a cup-shaped mask, comprising the following steps:

[0081] Step S1, mold preparation and material preparation: prepare the molds required for the production process, the molds are divided into concave molds and punches, and the shape of the mold clamping part is consistent with the shape of the cup-shaped mask; prepare production materials, the middle filter layer of the mask, and the inner layer of the mask. material and the outer layer of the mask; among them, the filter layer in the middle of the mask is 50g / m 2 of meltblown polypropylene electret and 50g / m 2 The electrostatic cotton fiber material composite, the outer layer of the mask is 25g / m 2 Non-woven fabric, the inner layer of the mask is 150g / m 2 Needle-punched cotton;

[0082] Step S2, feeding: the middle filter layer material of the mouth mask is sandwiched between the outer layer material of the mouth mask and the inner layer material of...

PUM

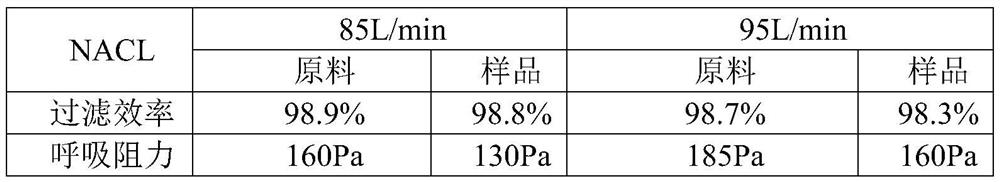

| Property | Measurement | Unit |

|---|---|---|

| Breathing resistance | aaaaa | aaaaa |

| Breathing resistance | aaaaa | aaaaa |

| Breathing resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com