Movable sludge filter pressing device and technological process thereof

A sludge filter press and sludge technology, applied in sludge treatment, water/sludge/sewage treatment, mixer with rotating stirring device, etc., can solve the problem that it is not suitable to establish a sludge treatment system and cannot build sludge Treatment system, poor sludge treatment effect, etc., to save input costs and follow-up maintenance costs, avoid less sewage, and facilitate treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

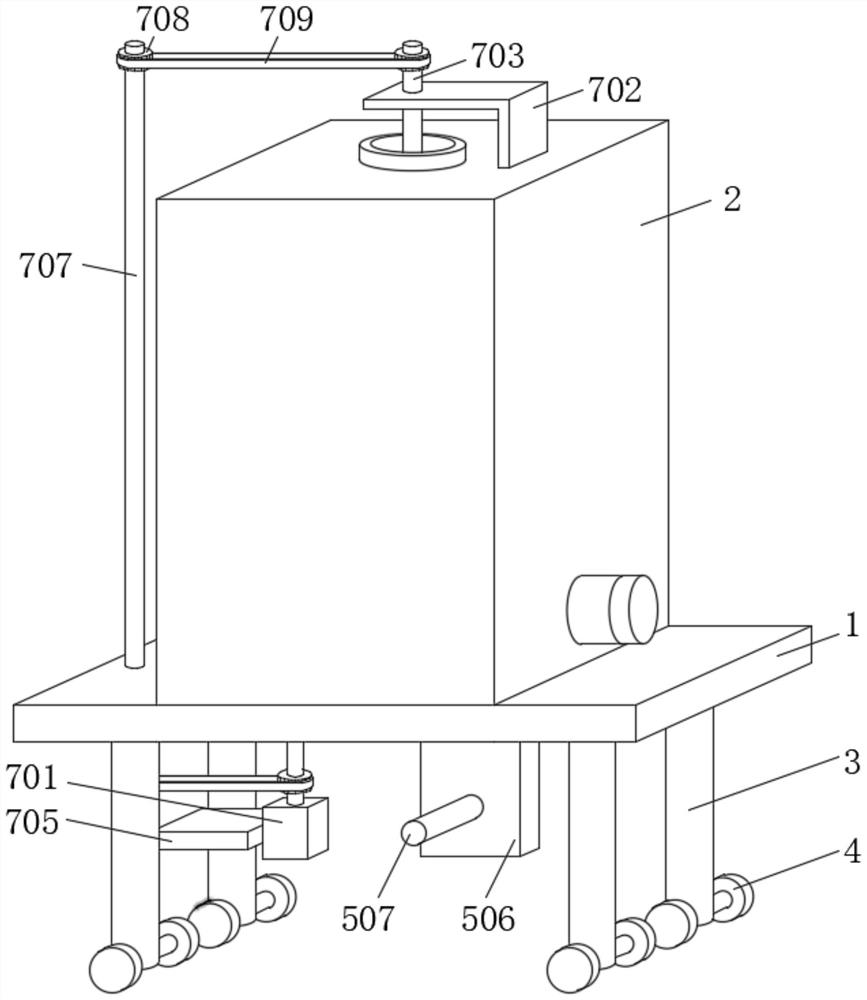

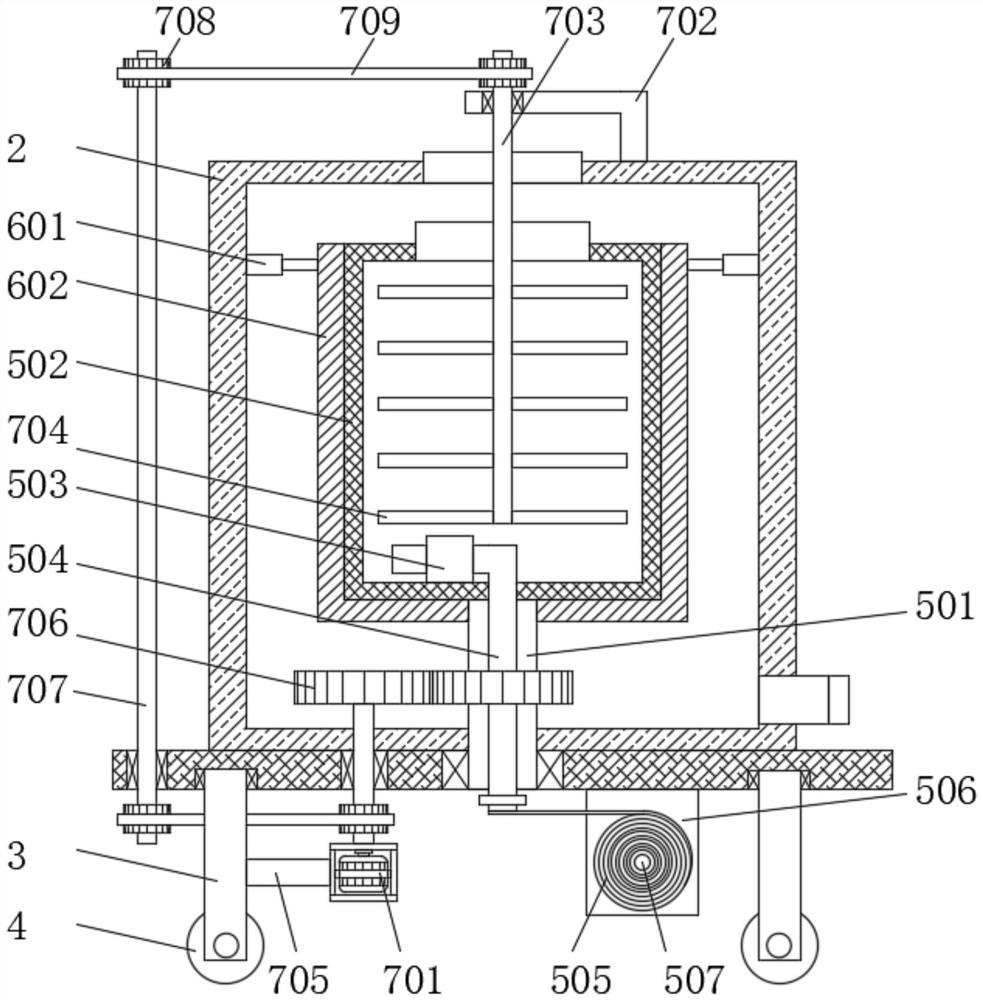

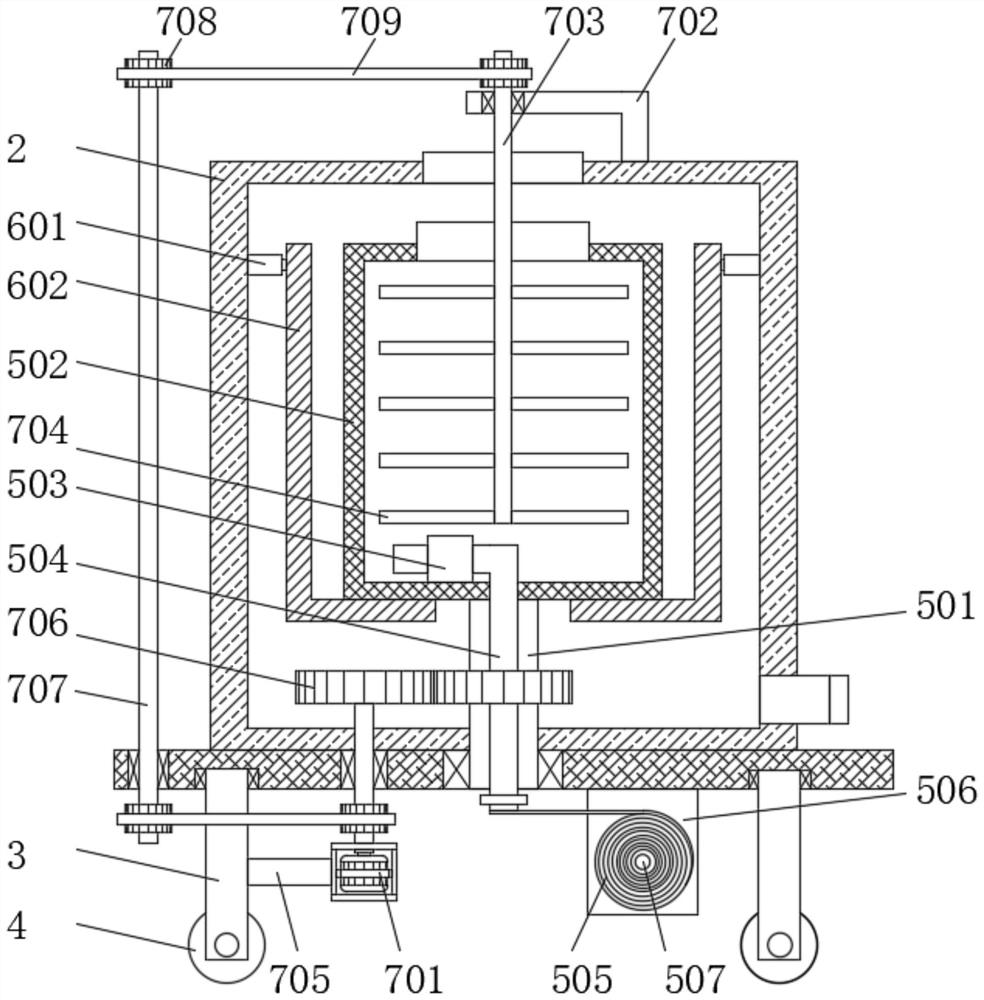

[0044] A mobile sludge filter press device comprises a base 1, a fixed box 2 is fixedly connected to the top of the base 1, a vertical rod 3 is symmetrically rotatably connected to both sides of the bottom of the base 1, and a rotating shaft is rotatably connected to the bottom end of the vertical rod 3, Both ends of the rotating shaft are fixed with rollers 4. A material collection mechanism is arranged between the base 1 and the fixed box 2. The material collection mechanism includes a cylindrical rod 501, a cylindrical box 502, a sludge pump 503 and a connecting pipe 504. The cylindrical rod 501 rotates Connected to the base 1, the cylindrical box 502 is fixed on the top of the cylindrical rod 501, the sludge pump 503 is arranged inside the cylindrical box 502, and the connecting pipe 504 is arranged on the sludge pump 503;

[0045] Specifically, the top of the fixed box 2 is provided with an opening, and the bottom of the right side of the fixed box 2 is provided with a wat...

Embodiment 2

[0062] A mobile sludge filter press device comprises a base 1, a fixed box 2 is fixedly connected to the top of the base 1, a vertical rod 3 is symmetrically rotatably connected to both sides of the bottom of the base 1, and a rotating shaft is rotatably connected to the bottom end of the vertical rod 3, Both ends of the rotating shaft are fixed with rollers 4. A material collection mechanism is arranged between the base 1 and the fixed box 2. The material collection mechanism includes a cylindrical rod 501, a cylindrical box 502, a sludge pump 503 and a connecting pipe 504. The cylindrical rod 501 rotates Connected to the base 1, the cylindrical box 502 is fixed on the top of the cylindrical rod 501, the sludge pump 503 is arranged inside the cylindrical box 502, and the connecting pipe 504 is arranged on the sludge pump 503;

[0063] Specifically, the top of the fixed box 2 is provided with an opening, and the bottom of the right side of the fixed box 2 is provided with a wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com