Groove type electric intelligent manure fermentation turning and throwing machine

An electric and intelligent technology, applied in the fields of organic fertilizer, agriculture, climate change adaptation, etc., can solve the problems of inconvenient disassembly and transportation, inability to replace the site, low degree of intelligent control, etc., to ensure dryness and oxygen content, and easy disassembly. The effect of loading and transportation and improving the efficiency of turning and throwing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

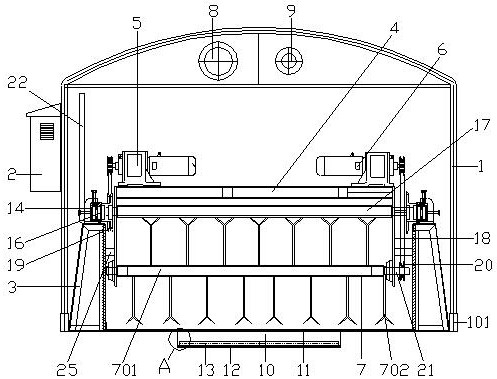

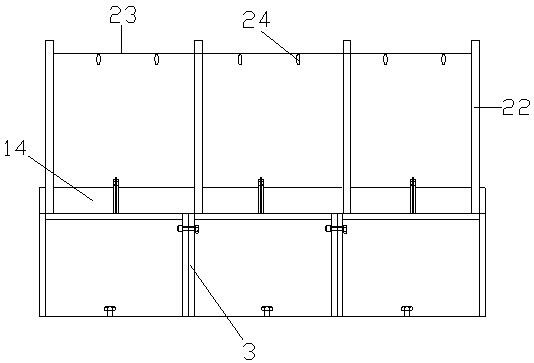

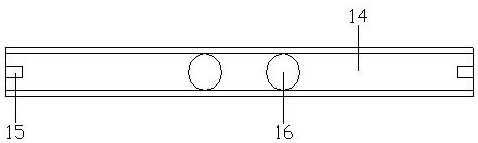

[0025] like figure 1 , 2 , 3 and 4, a trough-type electric intelligent manure fermentation turning and throwing machine includes a thermal insulation greenhouse 1, a power distribution control box 2, a tank side wall 3, an installation platform 4, a walking motor 5, a turning and throwing motor 6 and Turning and throwing mechanism 7, the bottom of the vertical steel frame on the left and right sides of the thermal insulation greenhouse 1 is provided with a pin pipe 101 to fix it, the outer side is provided with a power distribution control box 2, and the beam steel frame in the middle of the interior is provided with a dehumidification fan 8 and a power supply. The oxygen fan 9 is provided with the tank side walls 3 near the vertical steel frames on the left and right sides. The tank side walls 3 all adopt a multi-section right-angled trapezoid connection structure; the bottom of each section of the tank side walls 3 They are all fixed by tightening bolts, and the opposite en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com