Organic modified polyaluminum sulfate alkali-free liquid accelerator, preparation method thereof and early-strength alkali-free liquid accelerator

A technology of polyaluminum sulfate and accelerator, which is applied in the field of organically modified polyaluminum sulfate alkali-free liquid accelerator and its preparation, early-strength liquid alkali-free accelerator, and can solve problems such as incompatibility of early-strength components , to achieve the effect of realizing early strength properties, improving homogeneity, and promoting transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

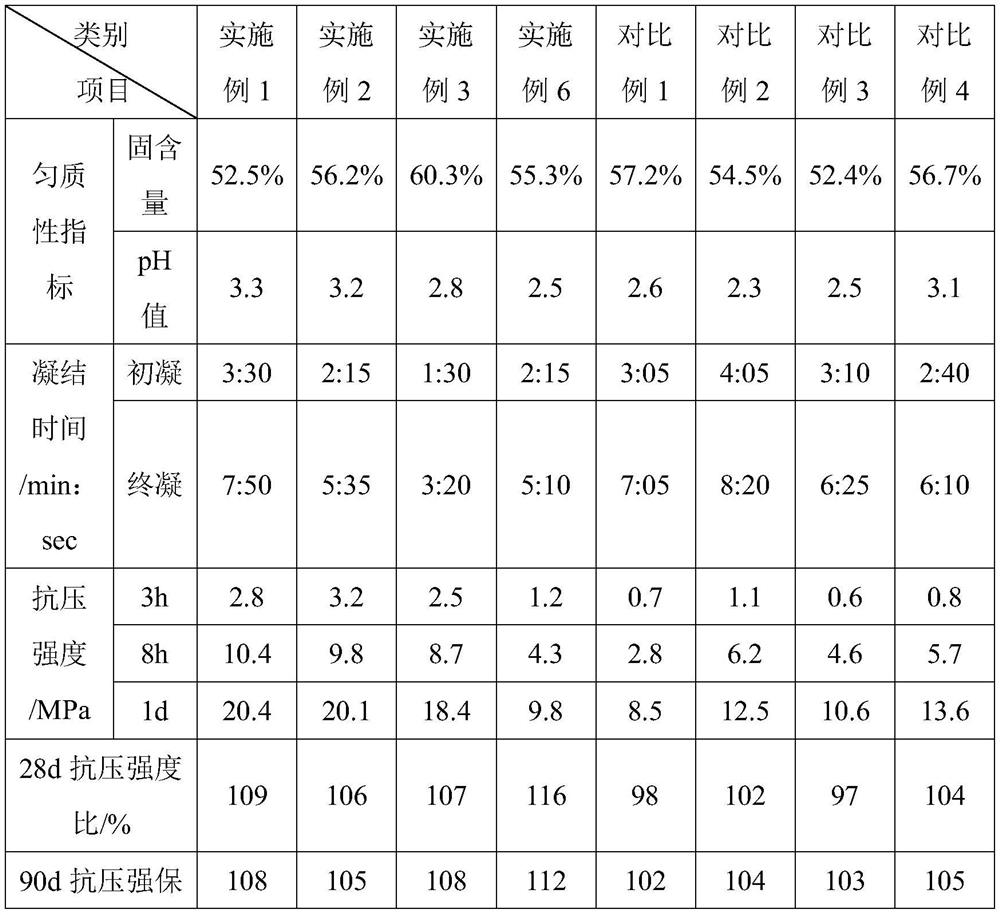

Examples

Embodiment 1

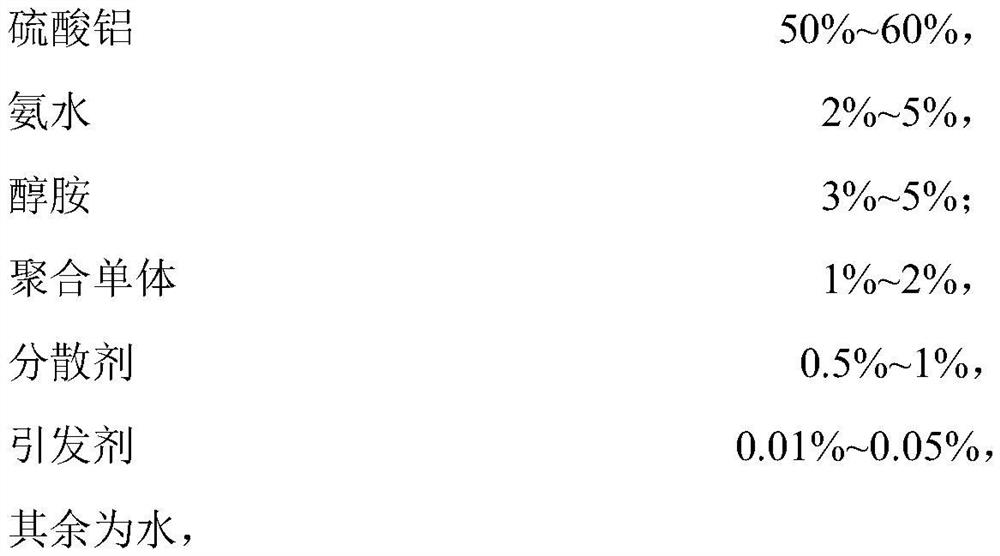

[0052] A preparation method of an early-strength organically modified polymeric aluminum sulfate alkali-free liquid accelerator, comprising the following steps:

[0053] (1) 50g aluminum sulfate is added in the reaction vessel that 43.49g water, 1.5g diethanolamine, 1.5g triethanolamine are housed, under the condition that temperature 50~60 ℃ and stirring speed are 250~300r / min, be incubated 0.5~ 1.0h; after the aluminum sulfate was completely dissolved, 2g of ammonia water was added dropwise, and the solution was kept warm for 6h to obtain a polyaluminum sulfate solution. Add 0.5g of acrylic acid, 0.5g of acrylamide, 0.3g of Span60 and 0.2g of Span80 to the reaction vessel containing the polyaluminum sulfate solution in turn, pass nitrogen for 0.5h to remove the air, and then add 0.01g of azodiisobutylamidine hydrochloric acid salt, the temperature is 50~60 ℃ constant temperature reaction 5h, obtains the organic modified polyaluminum sulfate emulsion.

[0054] (2) 79.5 g of ...

Embodiment 2

[0057] A preparation method of an early-strength organically modified polymeric aluminum sulfate alkali-free liquid accelerator, comprising the following steps:

[0058] (1) 55g aluminum sulfate is added in the reaction vessel that 35.57g water, 2.5g diethanolamine, 1.5g triethanolamine are housed, under the condition that temperature 50~60 ℃ and stirring speed are 250~300r / min, Heat preservation for 0.5 to 1.0 h; after the aluminum sulfate is completely dissolved, drop 3 g of ammonia water, heat preservation and aging for 6 h to obtain a polyaluminum sulfate solution. Add 0.5g of acrylic acid, 0.5g of acrylamide, 0.5g of N-methylol acrylamide, 0.3g of Span60, 0.3g of Span80 and 0.3g of Tween85 to the reaction vessel containing the polyaluminum sulfate solution in turn, and pass in 0.5h of nitrogen to remove air, then add 0.01 g of azobisisobutylamidine hydrochloride and 0.02 g of azobisisobutyronitrile, and react at a constant temperature of 50-60 DEG C for 5 hours to obtain ...

Embodiment 3

[0062] A preparation method of an early-strength organically modified polymeric aluminum sulfate alkali-free liquid accelerator, comprising the following steps:

[0063] (1) 60g aluminum sulfate is added in the reaction vessel that is equipped with 26.95g water, 3.0g diethanolamine, 1.0g triethanolamine, 1.0g triethanolamine, at temperature 50~60 ℃ and stirring speed are 250~300r / Under the condition of min, the temperature is kept for 0.5-1.0 h; after the aluminum sulfate is completely dissolved, 5 g of ammonia water is added dropwise, and the solution is heated and aged for 6 h to obtain a polyaluminum sulfate solution. 0.8g of acrylic acid, 0.8g of acrylamide, 0.4g of N-methylol acrylamide, 0.5g of Span60, and 0.5g of Tween85 were successively added to the reaction vessel containing the polyaluminum sulfate solution, and nitrogen was introduced for 0.5h to remove air, and then 0.03 g of azobisisoheptyl nitrile and 0.02 g of dimethyl azobisisobutyrate are added, and the temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com