Responsive porous ionic liquid crystal and preparation method thereof

A technology of ionic liquid crystals and liquid crystals, applied in the direction of liquid crystal materials, chemical instruments and methods, etc., can solve the problems of liquid-phase porous liquid transportation restricting practical industrial applications, affecting adsorption and separation performance, etc., to solve transportation problems, and the preparation method is simple and easy The effect of high operation and thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

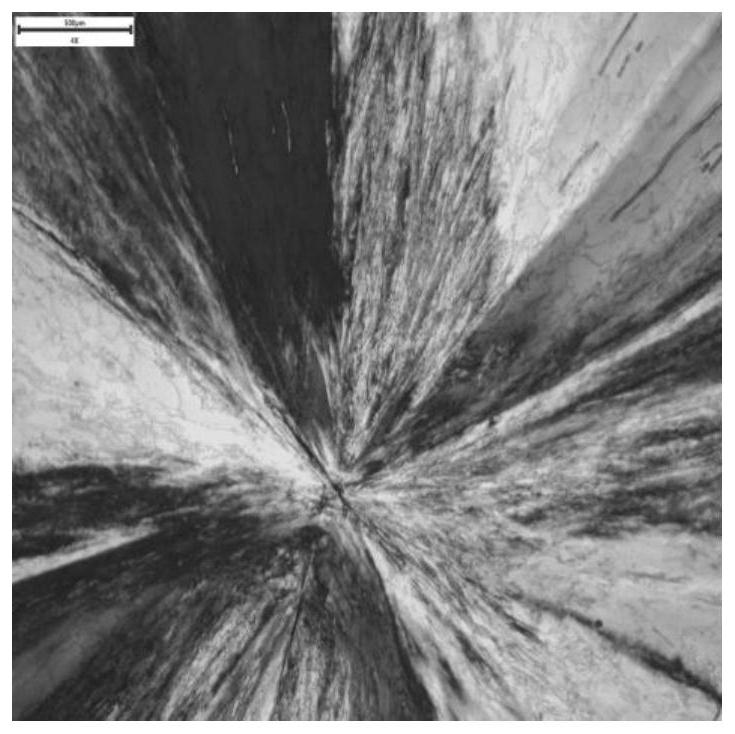

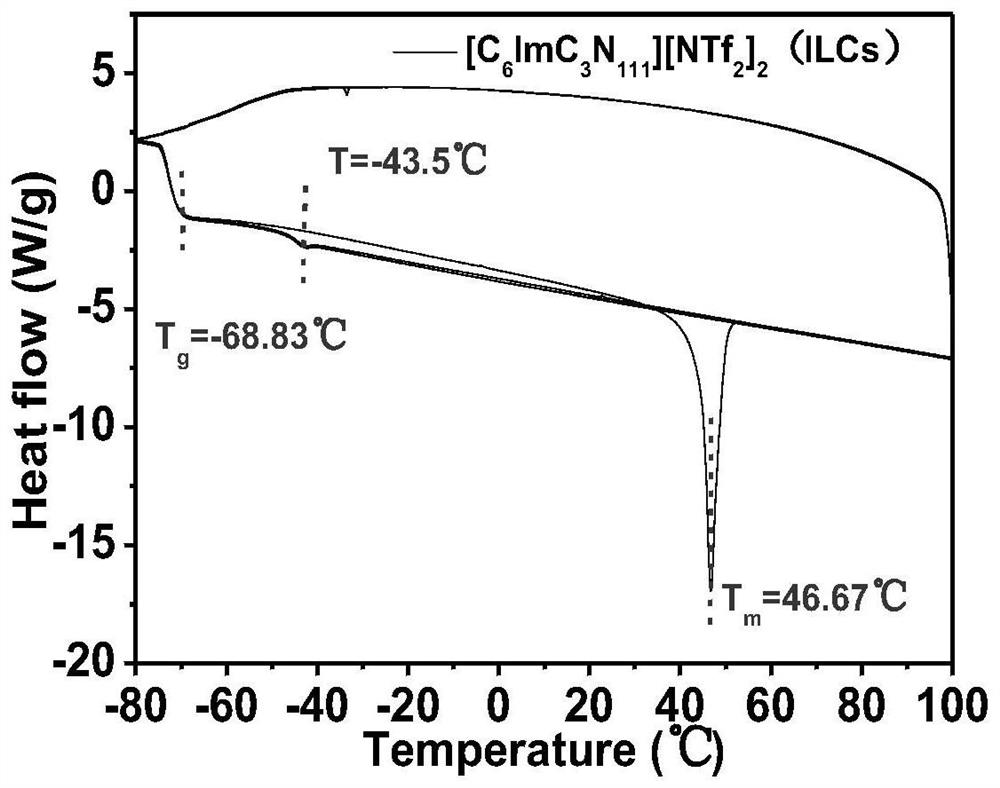

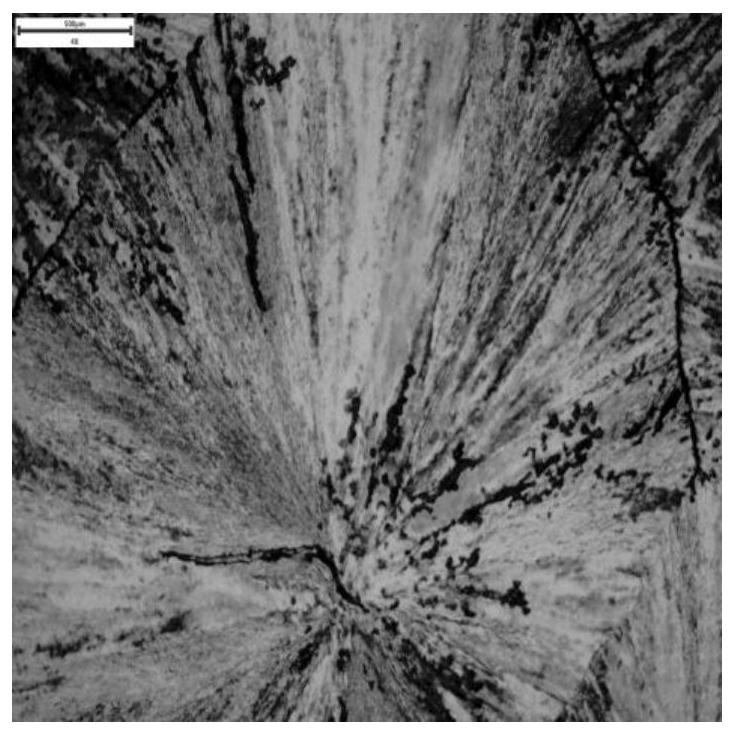

Embodiment 1

[0043] (1) Weigh 0.3g of ZIF-8 (200nm) and dissolve it in 10mL of methanol solvent, sonicate for 30mms to make it evenly dispersed;

[0044] (2) Weigh 5.7g of 1-hexane-3-propyltrimethylammonium bis-trifluoromethanesulfonimide salt [C 6 ImC 3 N 111 ][NTf 2 ] 2 , added to (1) at 25°C, magnetically stirred for 24 hours, the stirring rate was 400r / min, and the methanol solvent was naturally volatilized in the open;

[0045] (3) Dry in a vacuum oven at 70°C for 48 hours to obtain ZIF-8 (200nm) / [C 6 ImC 3 N 111 ][NTf 2 ] 2 -PLs (5wt%) porous liquid is standby;

[0046] (4) At 25°C, with a shear rate of 5rad / s and a time of 5mins, the porous ionic liquid crystal ZIF-8 (200nm) / [C 6 ImC 3 N 111 ][NTf 2 ] 2 - PLCs (5 wt%).

Embodiment 2

[0048] (1) Weigh 0.2g of ZIF-67 (450nm) and dissolve it in 15mL of methanol solvent, sonicate for 30mms to make it evenly dispersed;

[0049] (2) Weigh 1.8g of 1-decane-3-propyltrimethylammonium bistrifluoromethylsulfonimide salt [C 10 mime 2 ][NTf 2 ] 2 , added to (1) at 35°C, magnetically stirred for 24 hours, the stirring rate was 400r / min, and the methanol solvent was naturally volatilized in the open;

[0050] (3) Dry in a vacuum oven at 70°C for 24 hours to obtain ZIF-67 / [C 10 ImC 3 N 111 ][NTf 2 ] 2 -PLs (10wt%) porous liquid is standby;

[0051] (4) At 25°C, with a shear rate of 10rad / s and a time of 5mins, the porous ionic liquid crystal ZIF-67 / [C 10 ImC 3 N 111 ][NTf 2 ] 2 - PLCs (10 wt%).

Embodiment 3

[0053] (1) Weigh 0.2g of COF-1 and dissolve it in 15mL of ethanol solvent, sonicate for 30mms to make it evenly dispersed;

[0054] (2) Weigh 1.8g of 1-decane-3-propyltrimethylammonium bistrifluoromethylsulfonimide salt [C 10 mime 2 ][NTf 2 ] 2 , added to (1) at 35°C, magnetically stirred for 24 hours, the stirring rate was 500r / min, and the ethanol solvent was naturally volatilized in the open;

[0055] (3) Dry in a vacuum oven at 70°C for 24 hours to obtain COFs-1 / [C 10 ImC 3 N 111 ][NTf 2 ] 2 -PLs (10wt%) porous liquid is standby;

[0056] (4) At 25°C, the shear rate is 5rad / s, the time is 10mins, and the porous ionic liquid crystal COF-1 / [C 10 ImC 3 N 111 ][NTf 2 ] 2 - PLCs (10 wt%).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com