Ultraviolet aging resistant coating and preparation method thereof

An anti-ultraviolet aging and coating technology, applied in fiber processing, textiles and papermaking, fiber types, etc., can solve the problems of application range and service life, aging degradation, etc., and achieve low cost of raw materials, low cost, and universality. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] S1. Preparation of acetoacetyl-functionalized cellulose: 10 grams of cellulose and 10 grams of tert-butyl acetoacetate were dissolved in 200 ml of dimethyl sulfoxide, and reacted at 150° C. for 12 hours. After cooling, the above solution was poured into 1500 ml of ethanol to precipitate the acetoacetyl-functionalized cellulose, which was dried in a vacuum oven at 40° C. for 24 hours.

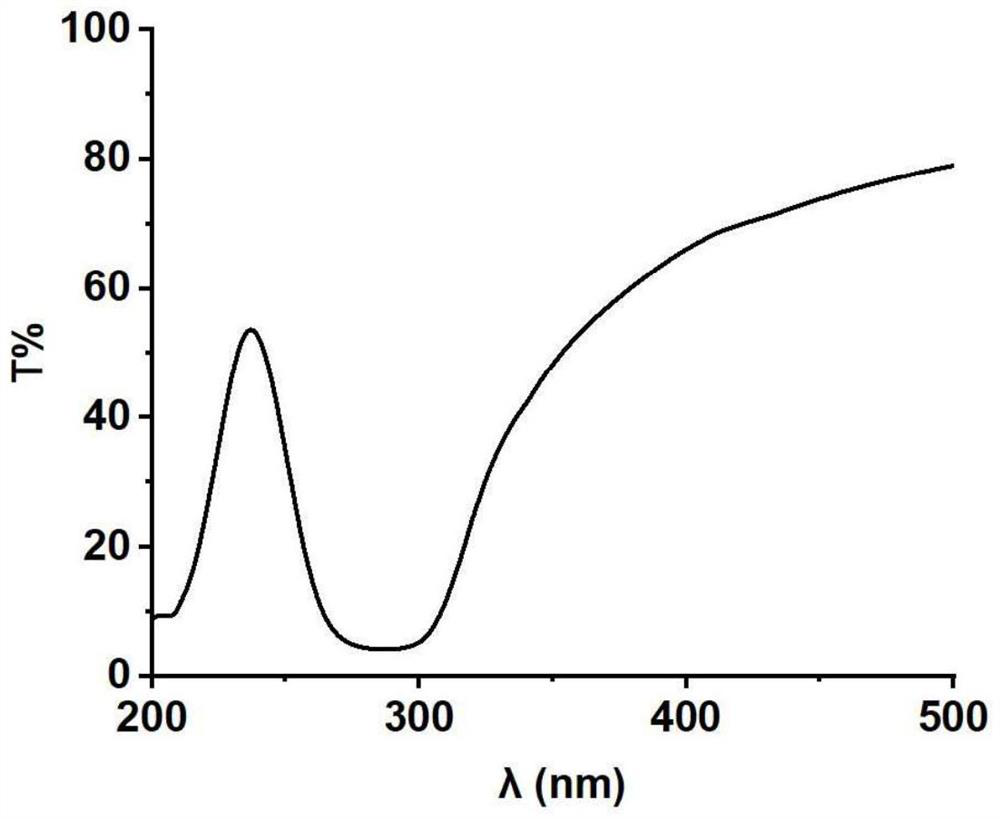

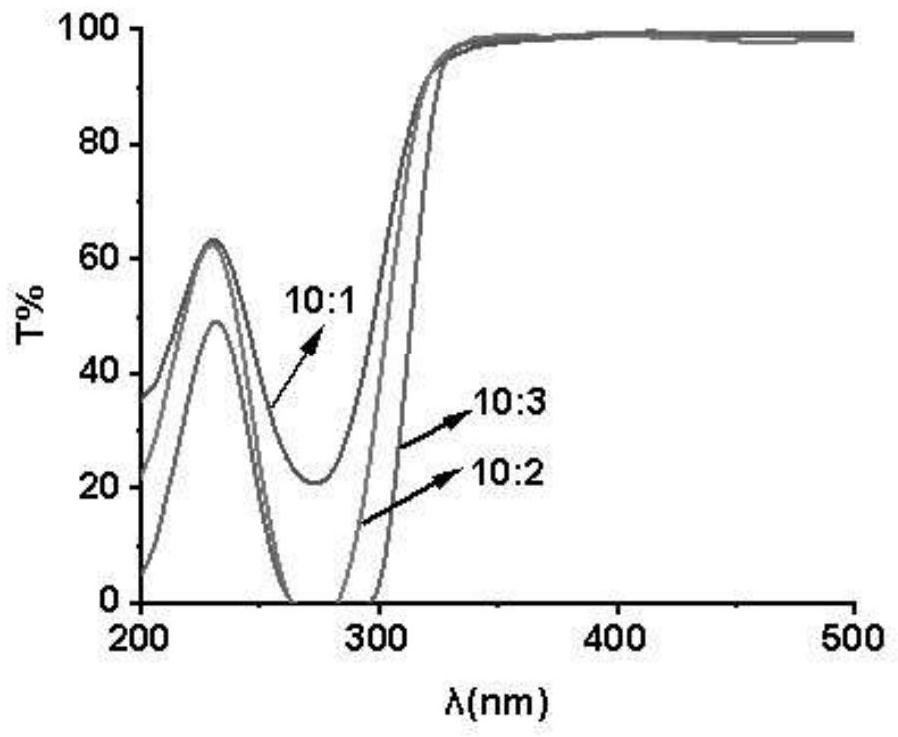

[0025] S2. Preparation of anti-ultraviolet aging coating sol solution: the acetoacetyl-functionalized cellulose obtained in step S1 and 1,8-octanediamine are dissolved in dimethylmethylene in a mass ratio of 10:3 as an amino accelerator In sulfone, a homogeneous solution with a concentration of 5% was prepared to prepare a sol solution of anti-ultraviolet aging coating, and its ultraviolet transmittance was measured;

[0026] S3. Preparation of anti-ultraviolet aging coating: coating the gel solution of anti-ultraviolet aging coating on the surface of poly-m-phenylene isophthalamide (meta...

Embodiment 2

[0028] The difference from Example 1 is that in step S2, the acetoacetyl-functionalized cellulose and polyetheramine D230 obtained in step S1 are amino accelerators and are dissolved in dimethyl sulfoxide with a mass ratio of 10:1. , configured into a homogeneous solution with a concentration of 3% to prepare an anti-ultraviolet aging coating sol solution, and measure its ultraviolet transmittance.

Embodiment 3

[0030] The difference from Example 1 is that the mass ratio of acetoacetyl-functionalized cellulose and polyetheramine D230 as amino accelerator is 10:2, and other conditions are not changed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com