Plunger piston shoe assembly

A plunger and sliding shoe technology, which is applied in the field of plunger sliding shoe components, can solve the problems of irregular shape of the sliding shoe, inconvenient extrusion and rolling of the sliding shoe, and achieve the effects of uniform shape, convenient rolling and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Attached to the following Figure 1-8 This application will be described in further detail.

[0038] Embodiments of the present application disclose a plunger shoe assembly.

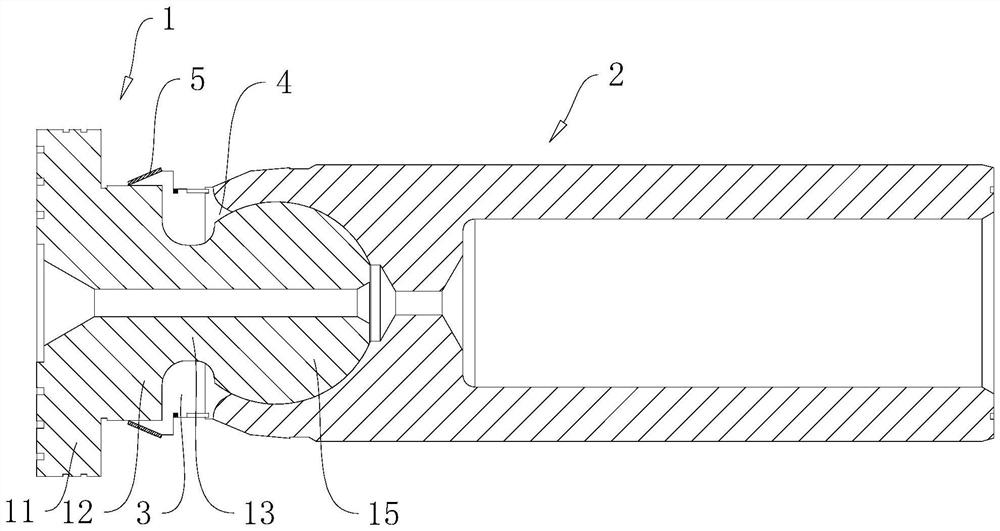

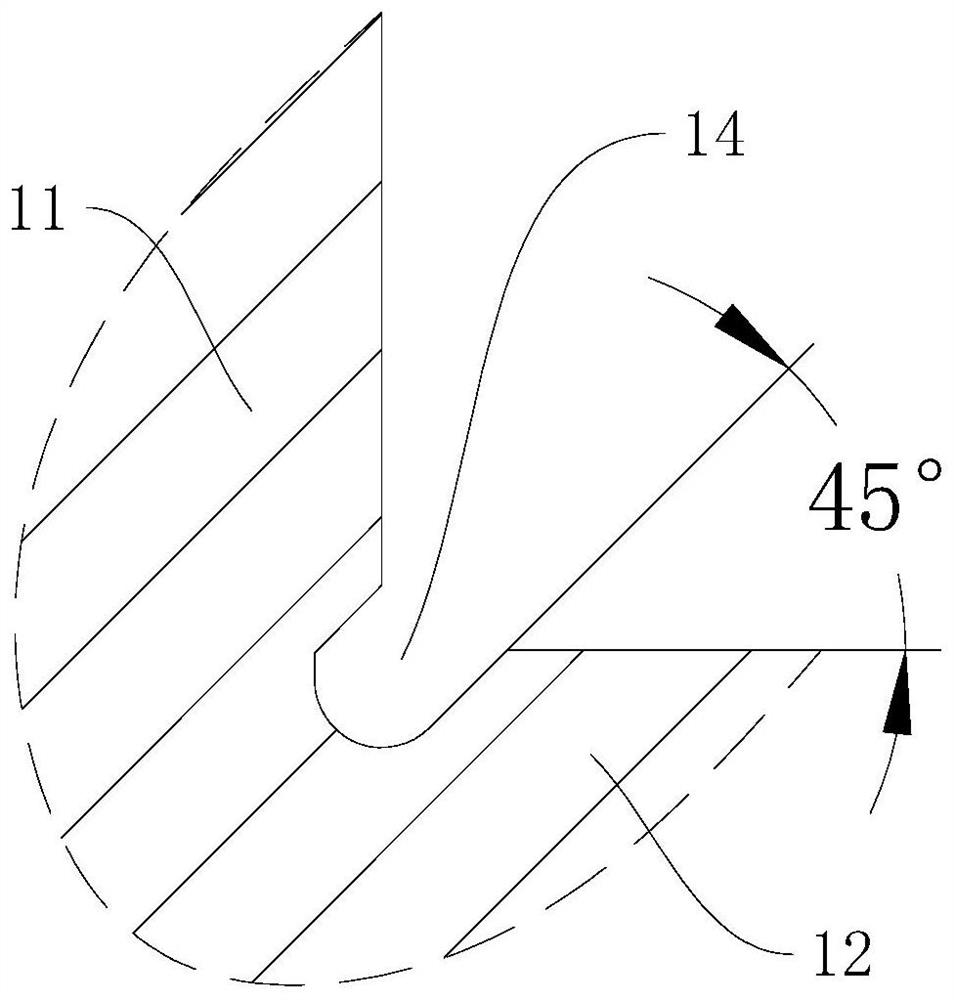

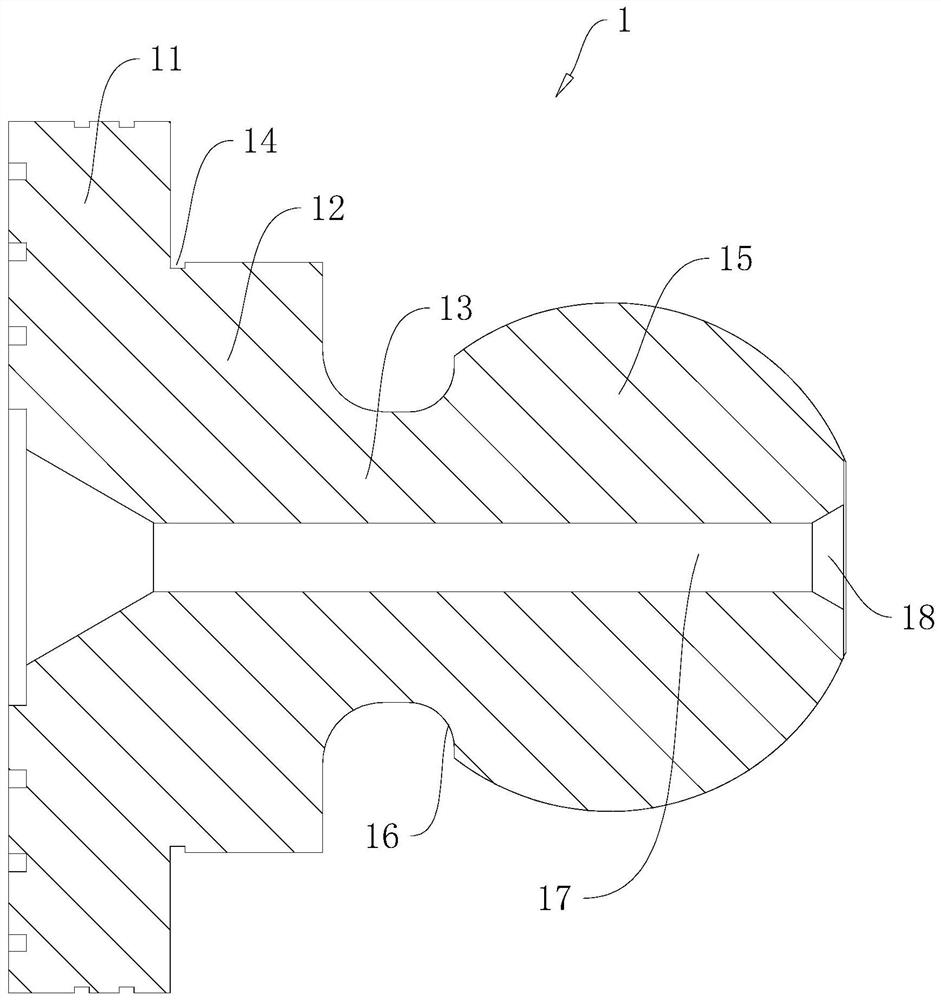

[0039] refer to figure 1 and figure 2 , a plunger sliding shoe assembly, including a sliding shoe 1, a plunger 2, a matching restricting assembly and a tightening ring 5, the sliding shoe 1 sequentially includes a connecting portion 11, a middle portion 12 and a neck portion 13 with diameters reduced in turn. The connection between the part 11 and the middle part 12 is provided with an undercut 14 , the undercut 14 is opened obliquely, and the undercut 14 is inclined in the direction of the connecting part 11 along the depth direction, and the inclination of the push groove is 45 degrees.

[0040] refer to image 3 , the sliding shoe 1 is integrally provided with a ball head 15, the ball head 15 is arranged at the end of the neck 13 away from the middle part 12, the diameter of the ball head ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com