Gradient utilization system for heat energy of polycrystalline silicon production system

A production system, polysilicon technology, applied in the direction of polycrystalline material growth, crystal growth, single crystal growth, etc., can solve the problem of increased steam energy consumption in the system, reduce steam energy consumption, reduce system steam energy consumption, and steam energy consumption Optimized effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

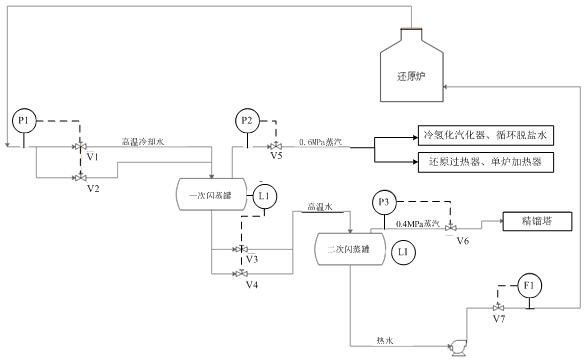

[0024] This embodiment relates to a cascade utilization system of thermal energy of a polysilicon production system.

[0025] Including the reduction furnace, the primary flash tank and the secondary flash tank connected in sequence, the water inlet of the primary flash tank is connected to the furnace barrel water outlet of the reduction furnace, the primary flash tank is provided with a 0.6Mpa steam outlet, and the outlet of the primary flash tank is The water outlet is connected to the water inlet of the secondary flash tank, the 0.4Mpa steam outlet is set on the secondary flash tank, and the water outlet of the secondary flash tank is connected to the furnace barrel water inlet of the reduction furnace.

[0026] Among them, the 0.6Mpa steam is used to provide the steam heat source for the cold hydrogenation process, the tail gas adsorption process and the reduction process, and the 0.4MPa steam is used to provide the heat source for the rectification process. Therefore, in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com