Built-in heat preservation type molten aluminum transfer ladle

A transfer bag, aluminum water technology, applied in metal processing equipment, manufacturing tools, casting melt containers, etc., can solve problems such as affecting aluminum water heat preservation and production safety, reducing the amount of aluminum loaded, difficult to clean, etc., to improve production inconvenience. , The effect of improving the quality of aluminum water and prolonging the life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

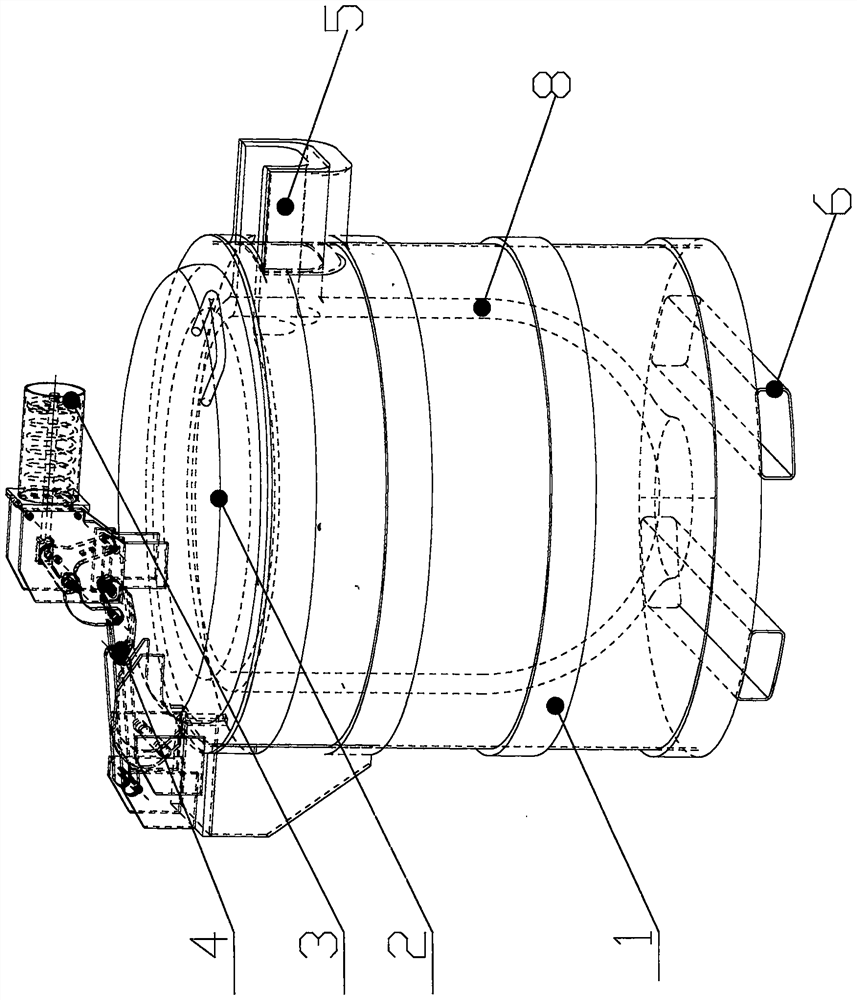

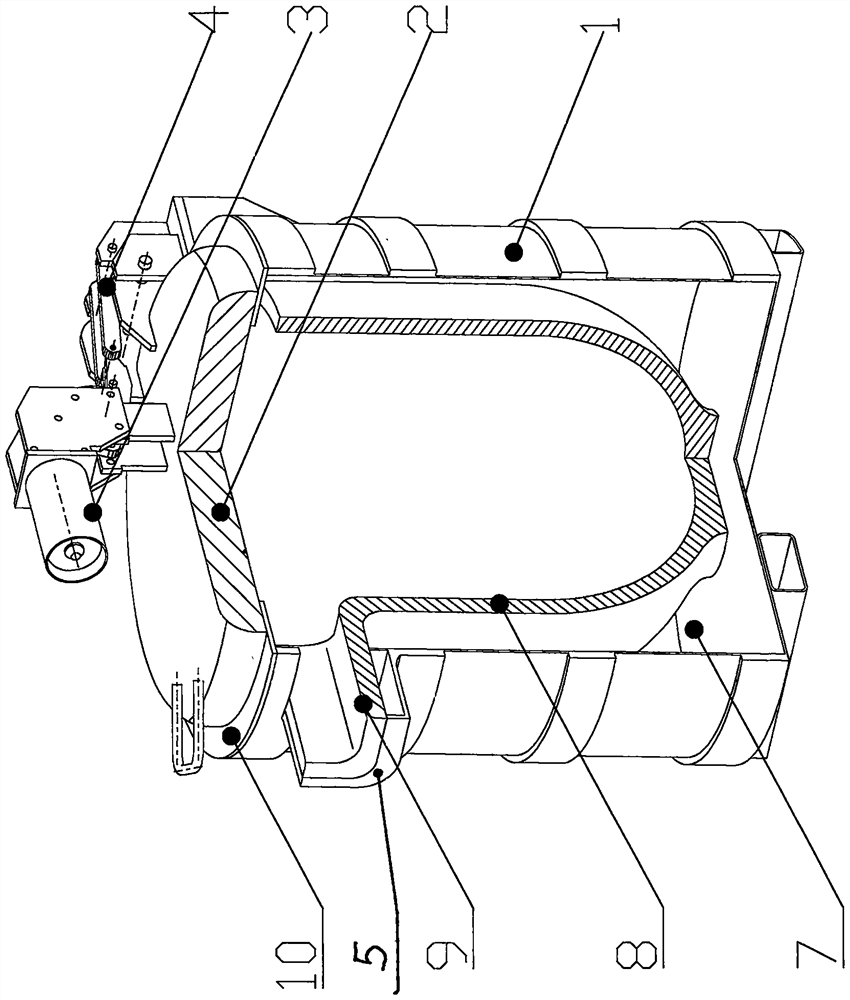

[0010] Refer to the attached figure 1 , figure 2 , the present invention has a built-in thermal insulation type aluminum water transfer bag, including a transfer bag 1, a transfer bag cover 2, a nozzle 5 (for pouring aluminum water) is installed on the upper part of the transfer bag 1, and a fork hole is provided on the lower part of the transfer bag 1 6 (for forklift insertion and transfer), an anti-stick inner liner 8 is housed in the transfer envelope 1, and a thermal insulation layer 7 is installed between the transfer envelope 1 and the anti-stick inner liner 8 (for thermal insulation) , the material of the anti-stick inner liner 8 is a graphite crucible, and the material of the insulation layer 7 is refractory asbestos (high temperature resistance and thermal insulation). A pressure plate 10 is installed between the transfer bag cover 2 and the anti-stick inner liner 8 for pressing and fixing. The pressure plate is locked by screws and can be flexibly disassembled, whi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com