Production device and method for gasified wastewater crystal salt

A technology of a production device and a production method, applied in the field of crystalline salts, can solve the problems of inability to respond flexibly, excessive and small amounts, and simple way of adding drugs, so as to improve crystallization efficiency and filtration effect, prevent neutralization reaction, and save time and cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

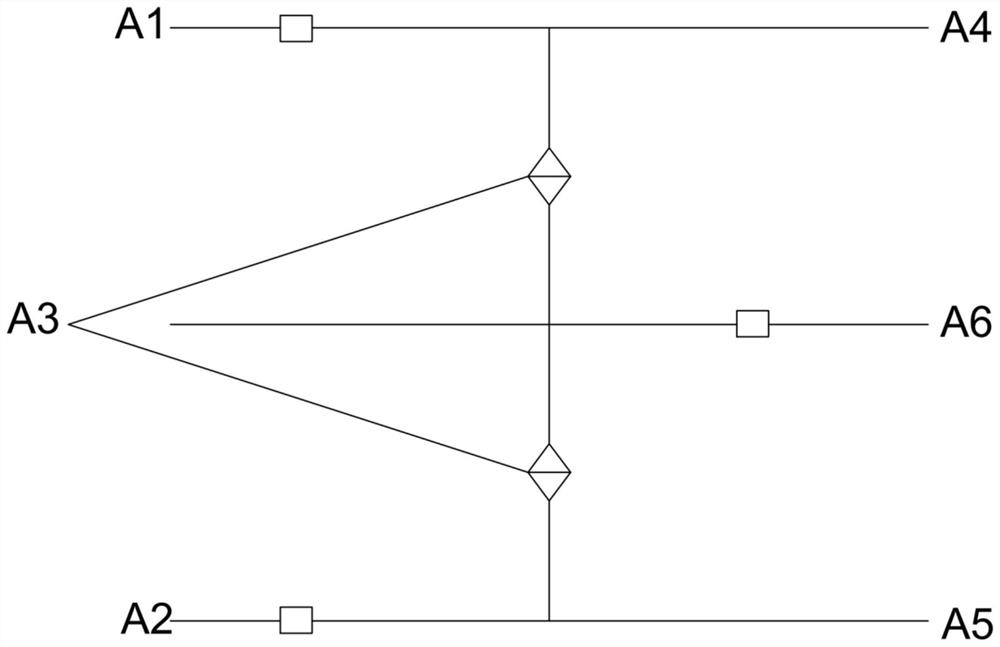

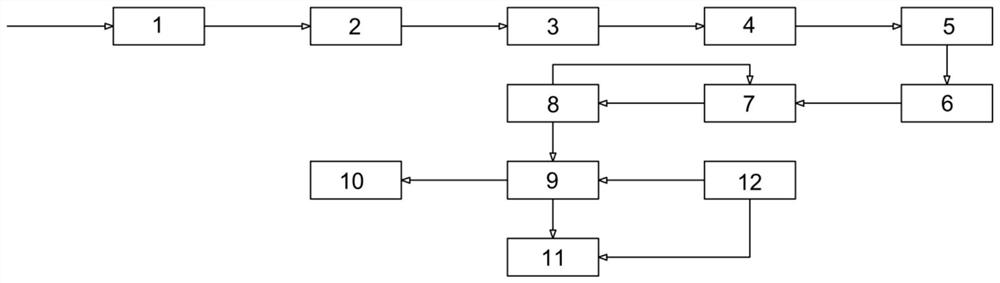

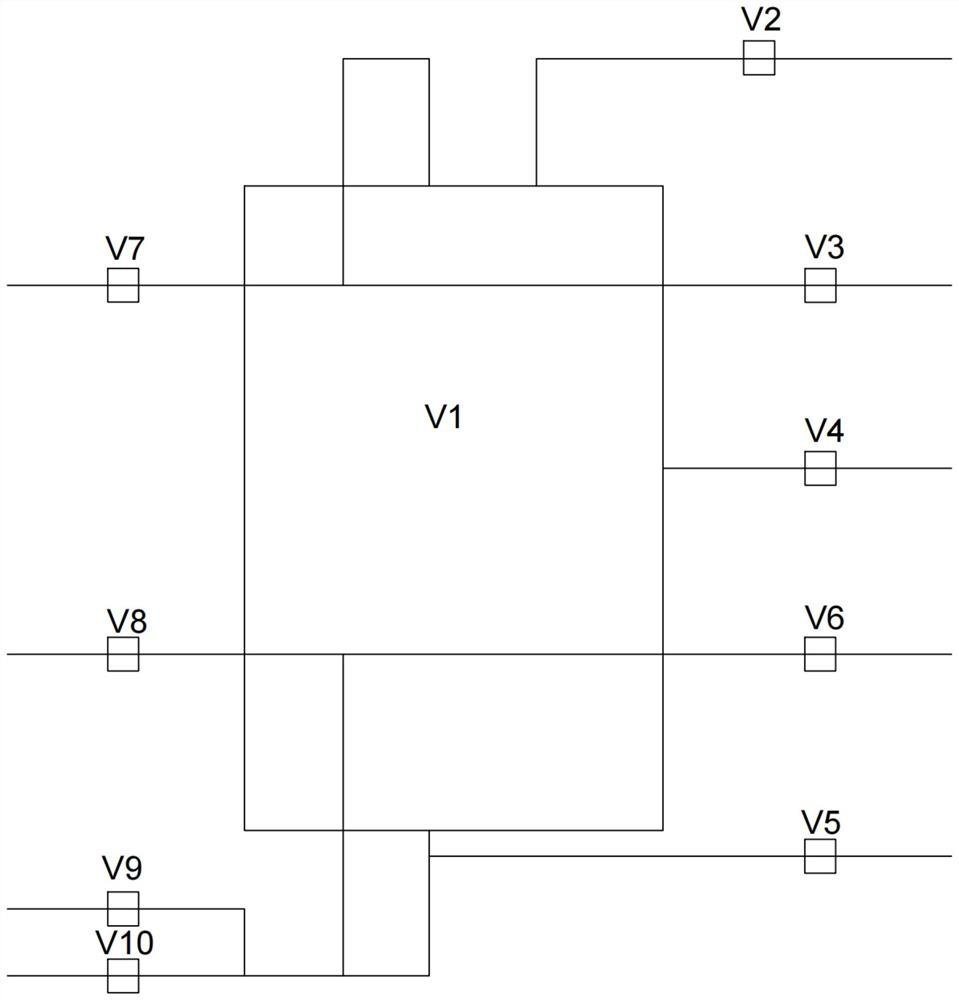

[0029] The application relates to a production device for crystalline salt of gasification wastewater. The device includes a reduction auxiliary unit, a reduction unit and a crystalline salt unit.

[0030] A reduction auxiliary unit is used to pretreat various compounds in the gasification wastewater.

[0031] The reduction unit is used for performing at least one reduction step to obtain a reduced amount of produced water from the gasification wastewater, thereby obtaining a reduced amount of concentrated water.

[0032] The crystallized salt unit is used to evaporate and crystallize the reduced concentrated water.

[0033] Both the reduction auxiliary unit and the reduction unit are provided with a dosing module. The dosing module adds the first component and / or the second component to the gasification wastewater treated in the reduction auxiliary unit or the reduction unit. The dosing module controls the addition amount of the first component and / or the second component,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com