Vernier sensitization optical fiber air pressure sensor combined with coating technology and preparation method of vernier sensitization optical fiber air pressure sensor

A technology of air pressure sensor and optical fiber, which is applied in fluid pressure measurement using optical methods, cladding optical fiber, instruments, etc., can solve the problem of low air pressure sensitivity, and achieve the effects of easy preparation, low preparation technical requirements, and great application potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

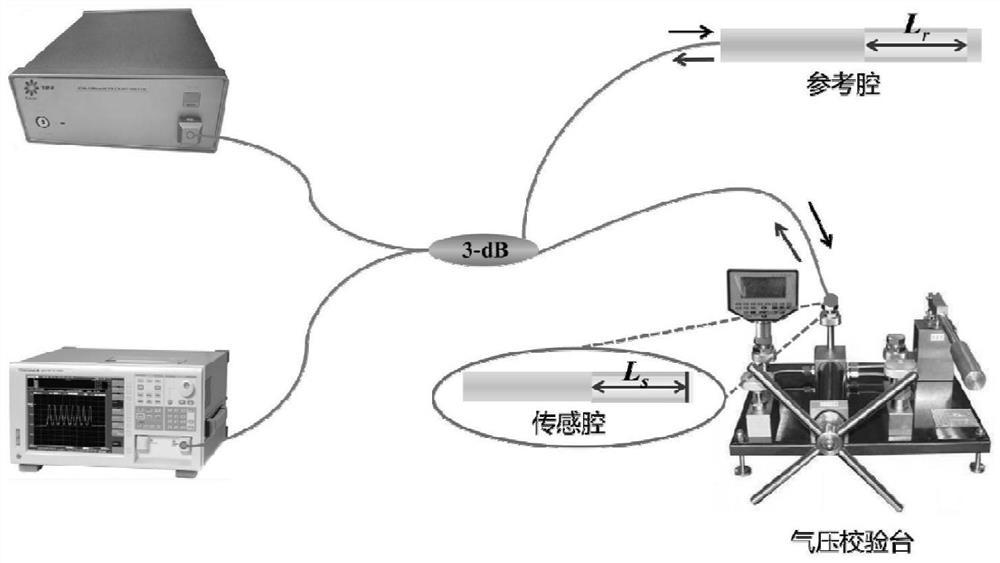

[0028] Embodiment 1: The vernier-sensitized optical fiber air pressure sensor combined with the coating technology in this embodiment includes a broadband light source, a spectrum analyzer and a 3-dB coupler, as well as a microcavity FPI-1 and a microcavity FPI-2;

[0029] Among them, the output end of the broadband light source and the input end of the spectrum analyzer are respectively connected to one port of the 3dB coupler through an optical fiber; the microcavity FPI-1 and the microcavity FPI-2 are connected in parallel and are respectively connected to the two ports of the 3dB coupler through an optical fiber ;

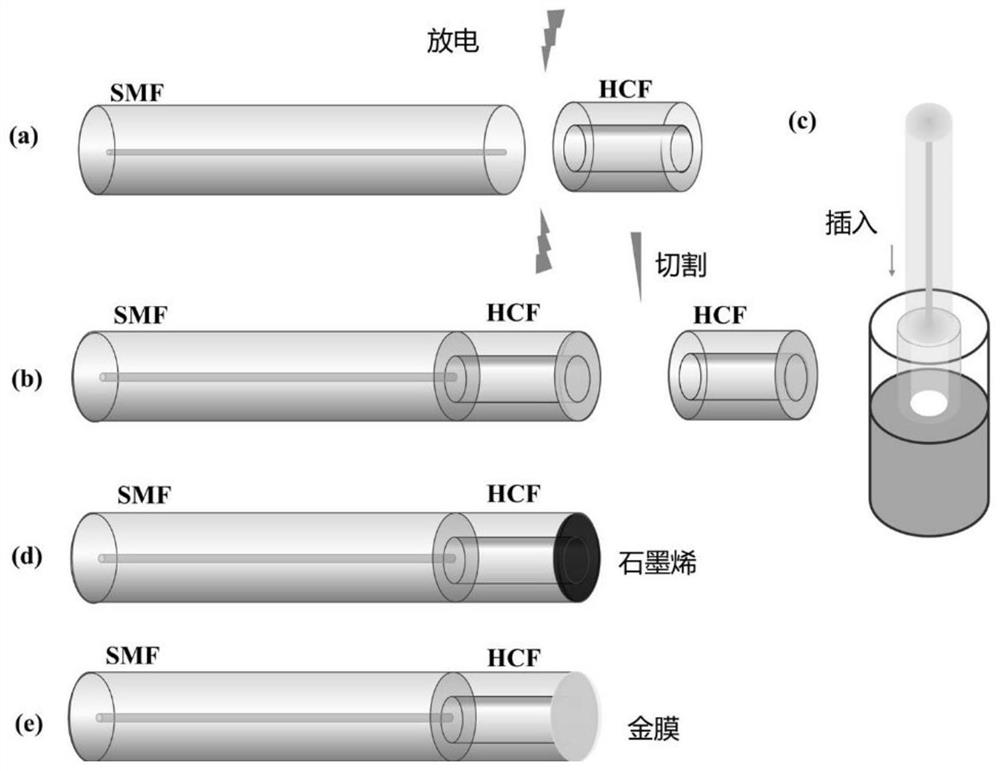

[0030] The microcavity FPI-1 is made by splicing one end of a single-mode fiber with a flat end face and a hollow core fiber with a flat end face, and the other end of the hollow core fiber is sequentially coated with graphene oxide film and gold film to seal the hollow core fiber;

[0031] The microcavity FPI-2 is made of two single-mode fibers and a hollow-co...

specific Embodiment approach 2

[0050] Embodiment 2: The difference between this embodiment and Embodiment 1 is that: L s 157μm, L r is 166 μm. Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0051] Specific embodiment three: the preparation method of the cursor-sensitized optical fiber air pressure sensor combined with the coating technology in this embodiment:

[0052] A. Preparation of microcavity FPI-1

[0053] A-1. Peel off the coating of the hollow core fiber and single-mode fiber, and wipe the coated single-mode fiber and hollow-core fiber with non-woven fabric dipped in alcohol repeatedly in one direction, and then use a fiber cleaver Cut the end faces of single-mode fibers and hollow-core fibers flat;

[0054] A-2. Weld the flattened end face of the single-mode fiber with the flattened end face of the hollow core fiber, and then keep the length of the hollow core fiber as L s , cut the other end face of the hollow-core fiber flat, and then coat it with a graphene oxide film;

[0055] A-3. Coating gold film on the outside of graphene oxide film;

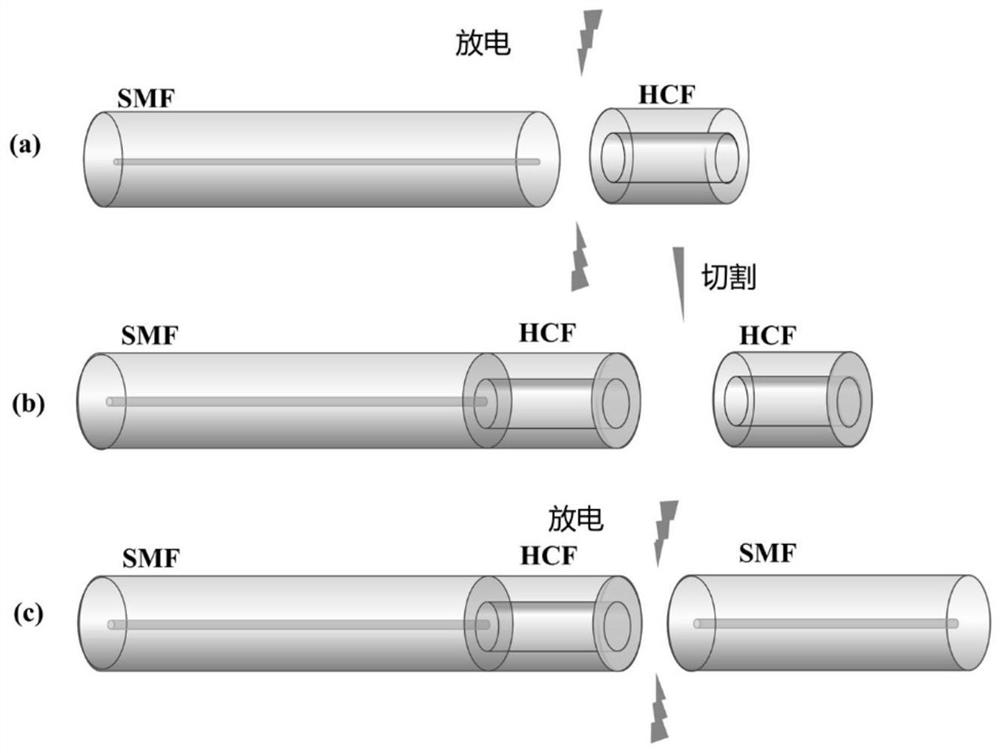

[0056] B. Preparation of microcavity FPI-2: peel off the coating of the hollow-core fiber and the two-segmen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Inner diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com