AI visual inspection equipment and system for shell structure defect detection

A technology of visual inspection and shell structure, applied in the field of visual inspection, can solve the problems of incomplete inspection of all sides of the product, large space of inspection equipment, and easy deviation of rotation angle, so as to achieve simple and fast transmission direction change and avoid operation. The effect of many processes and less difficulty in process production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

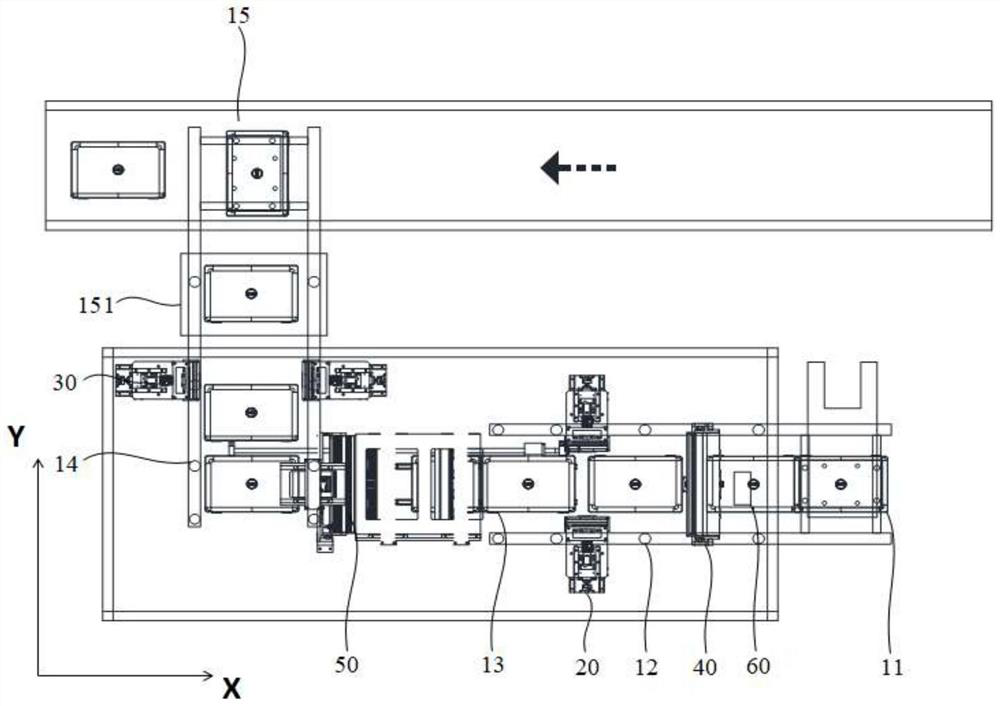

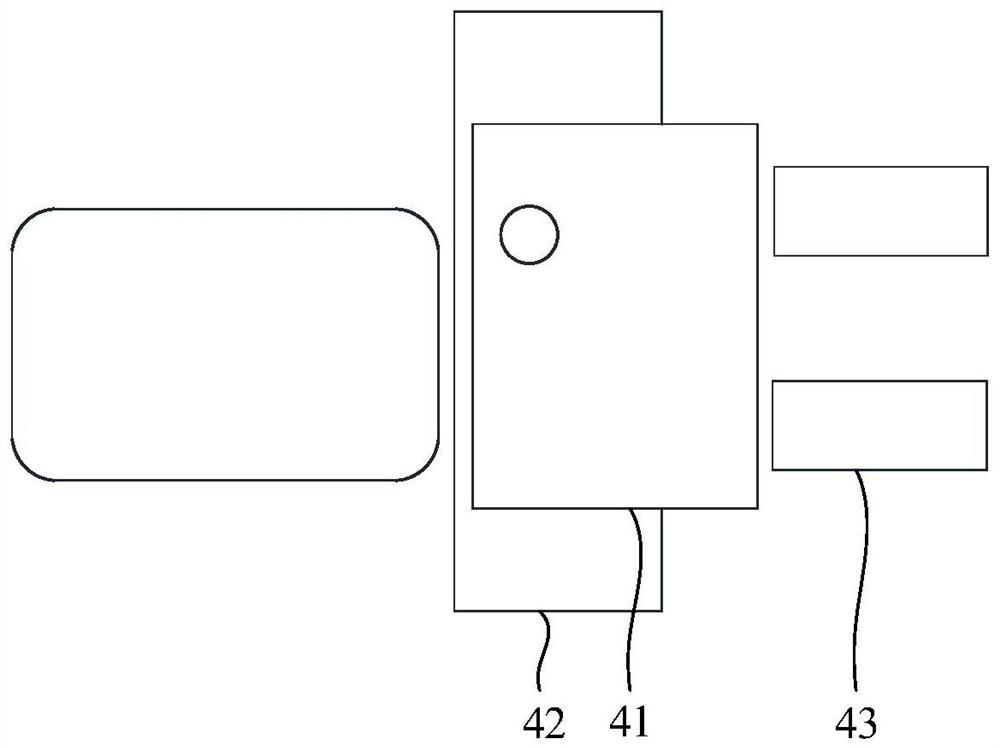

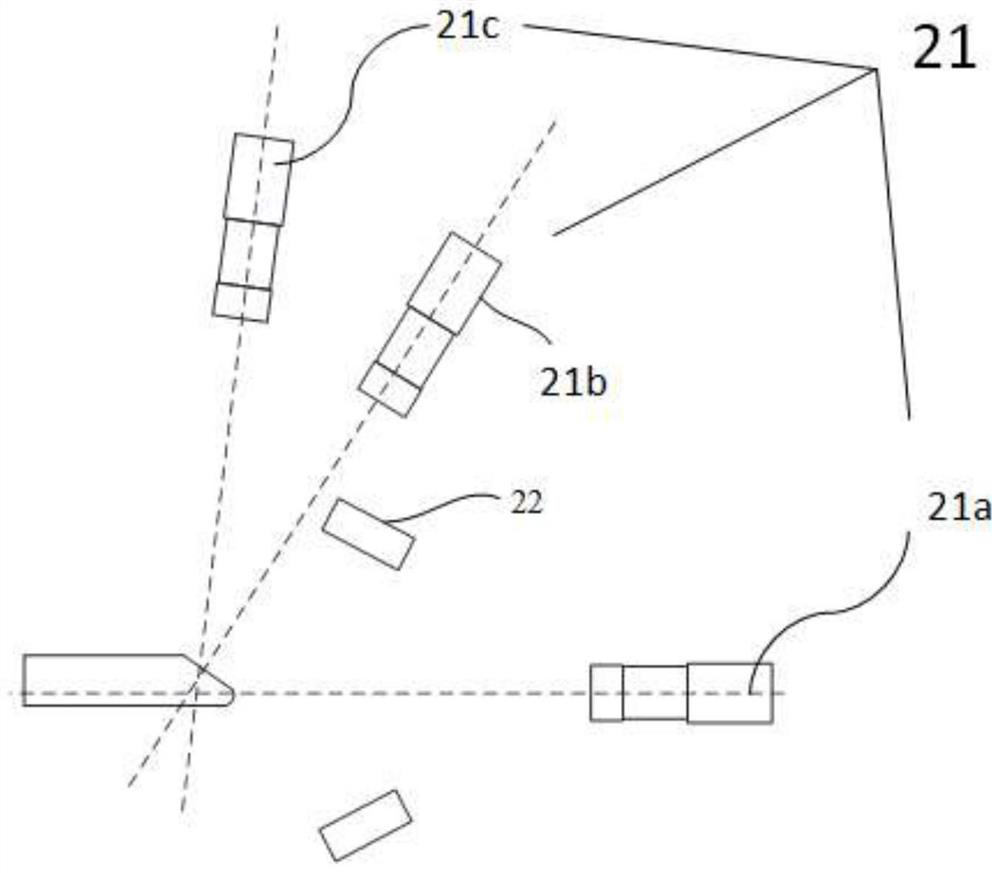

[0069] Please refer to Figure 1-Figure 9 , AI visual inspection equipment, including:

[0070] Transmission structure, one end of the transmission structure is the material loading position 11, the other end of the transmission structure is the material lowering position 15, the transmission structure has a transmission position for the housing structure to move, and the transmission position includes: a first The transmission segment and the second transmission segment, and the transmission directions of the first transmission segment and the second transmission segment are different;

[0071] Two first side visual detection devices 20, two of the first side visual detection devices 20 are respectively arranged on both sides of the first transmission section of the transmission position;

[0072] Two second side visual detection devices 30, two of the second side visual detection devices 30 are respectively arranged on both sides of the second transmission section of the tr...

Embodiment 2

[0130] Based on the AI visual inspection device in the above embodiment, the present invention further provides an AI visual inspection system, including an industrial computer, a quality inspection server, and the aforementioned AI visual inspection device;

[0131] The industrial computer is connected to the AI visual inspection device to control the AI visual inspection device and receive inspection information, and the industrial computer is wired or wirelessly connected to the quality inspection server to transmit inspection information and obtain identification result.

[0132] The industrial computer is responsible for scheduling each device to take pictures, uploading the pictures to the quality inspection server, calling the algorithm model and rule processing program deployed on the quality inspection server to identify and determine the defects, and finally send the identification results returned by the service to The industrial computer controls the correspo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com