Integrated electrode and preparation method and application thereof

A technology of electrodes and electrolytes, which is applied in the field of integrated electrodes and its preparation, can solve the problems of poor battery performance, poor electrolyte density, electrolyte and electrode interface impedance, etc., and achieve high density, improved magnification and cycle performance, and high energy density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

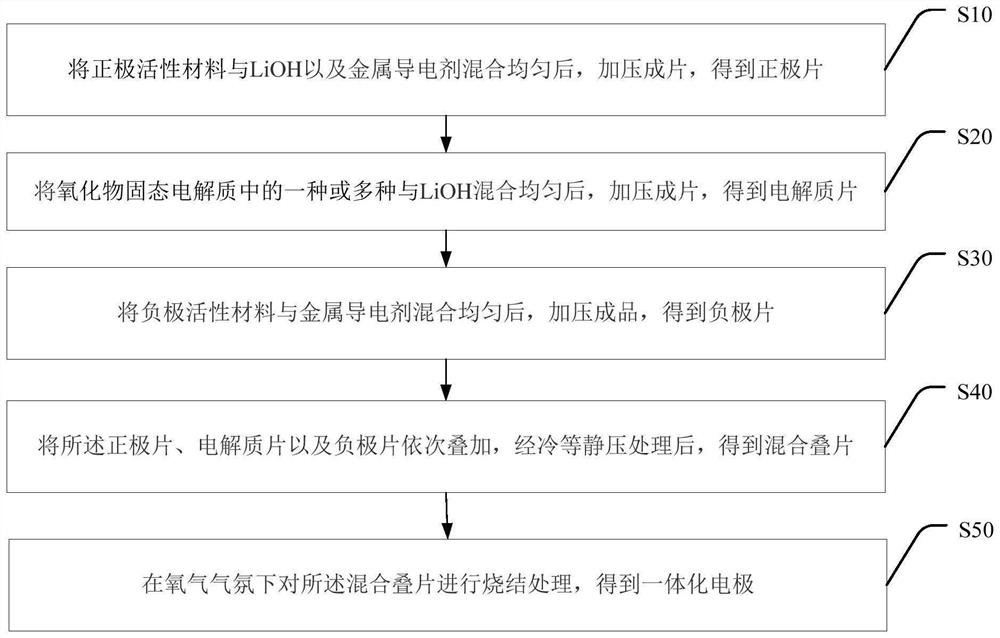

Method used

Image

Examples

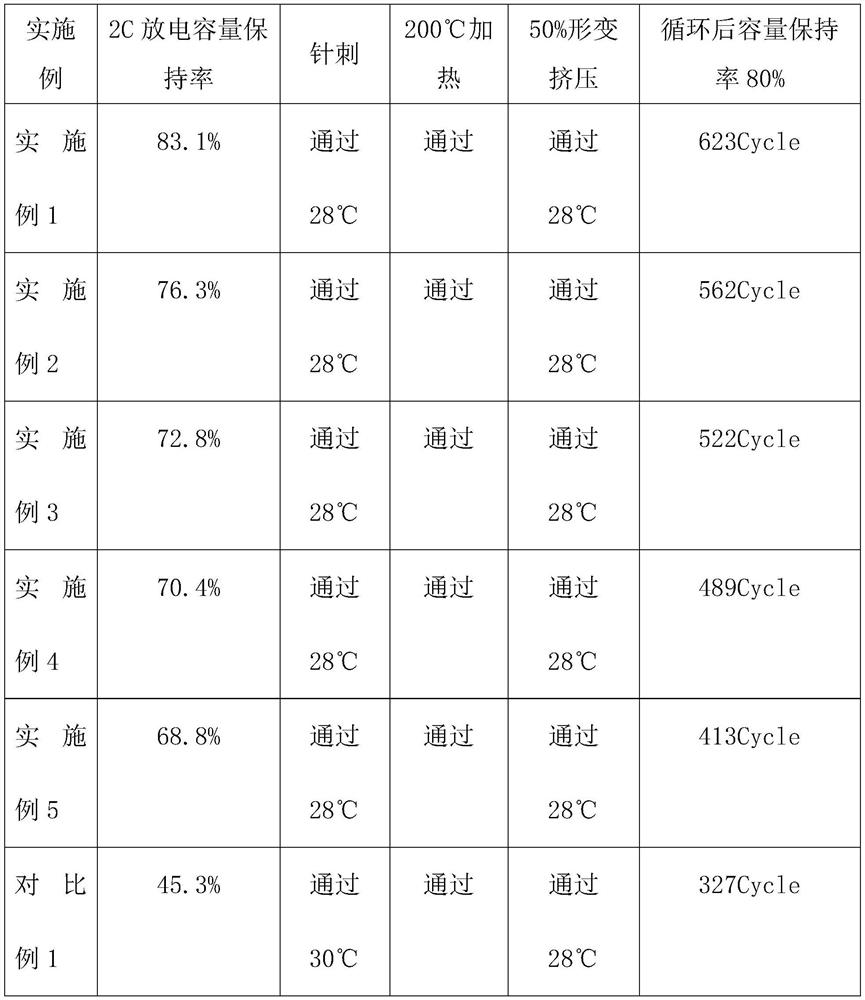

Embodiment 1

[0039] Step 1: Composite cathode configuration: the Ni 0.8 Co 0.1 Mn 0.1 (OH) 2 : LiOH (molar ratio 1:1), metal conductive agent accounted for 5%, mixed evenly and pressed into a sheet;

[0040] Step 2: Electrolyte (LATP) configuration: the NH 4 H 2 PO 4 :Al 2 O 3 :TiO 2 : LiOH (molar ratio 3:0.3:1.7:1.3) mixed evenly and pressed into tablets;

[0041] Step 3: Negative Configuration: Li 4 Ti 5 O 12 , The proportion of metal conductive agent is 5%, mixed evenly and pressed into pieces;

[0042] Step 4: Stack the sheet-like samples in the order of the composite positive electrode / electrolyte / negative electrode mixed pole pieces, and compact them by cold isostatic pressing;

[0043] Step 5: Place the samples pressurized in step 4 into a dry pot and then sintered in a quartz tube at 800°C under the addition of an oxygen atmosphere to obtain a highly dense chemical electrode-electrolyte integrated electrode;

[0044] Step 6: The electrode-electrolyte integrated electr...

Embodiment 2

[0046] Step 1: Composite cathode configuration: the Ni 0.8 Co 0.1 Mn 0.1 (OH) 2 : LiOH (molar ratio 1:1), metal conductive agent metal conductive ratio of 5%, mixed evenly and pressed into a sheet;

[0047] Step 2: Electrolyte (LLZO) configuration: La 2 O 3 : ZrO 2 : LiOH (molar ratio 1.5:2:7) is mixed evenly and pressed into tablets;

[0048] Step 3: Negative Configuration: Li 4 Ti 5 O 12 , The proportion of metal conductive agent is 5%, mixed evenly and pressed into pieces;

[0049] Step 4: Stack the sheet-like samples in the order of the composite positive electrode / electrolyte / negative electrode mixed pole pieces, and compact them by cold isostatic pressing;

[0050] Step 5: Place the samples pressurized in step 4 into a dry pot and then sintered in a quartz tube at 800°C under the addition of an oxygen atmosphere to obtain a highly dense chemical electrode-electrolyte integrated electrode;

[0051] Step 6: The electrode-electrolyte integrated electrode obtained...

Embodiment 3

[0053] Step 1: Composite cathode configuration: the Ni 0.8 Co 0.1 Mn 0.1 (OH) 2 : LiOH (molar ratio 1:1), metal conductive agent accounted for 5%, mixed evenly and pressed into a sheet;

[0054] Step 2: Step 2: Electrolyte (LATP) configuration: NH 4 H 2 PO 4 :Al 2 O 3 :TiO 2 : LiOH (molar ratio 3:0.3:1.7:1.3) mixed evenly and pressed into tablets;

[0055] Step 3: Negative configuration: SiO x , The proportion of metal conductive agent is 5%, mixed evenly and pressed into pieces;

[0056] Step 4: Stack the sheet-like samples in the order of the composite positive electrode / electrolyte / negative electrode mixed pole pieces, and compact them by cold isostatic pressing;

[0057] Step 5: Place the samples pressurized in step 4 into a dry pot and then sintered in a quartz tube at 800°C under the addition of an oxygen atmosphere to obtain a highly dense chemical electrode-electrolyte integrated electrode;

[0058] Step 6: The electrode-electrolyte integrated electrode obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com